TBM tunnel face front rock mass integrity drilling device and method

A technology of integrity and rock mass, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve problems that have not yet been developed and applied, and achieve the effect of ensuring safe and efficient construction, overcoming uncertainty, and high level of informationization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention. It should be understood that the embodiments described below are only a part of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained without making creative efforts belong to the protection scope of the present invention.

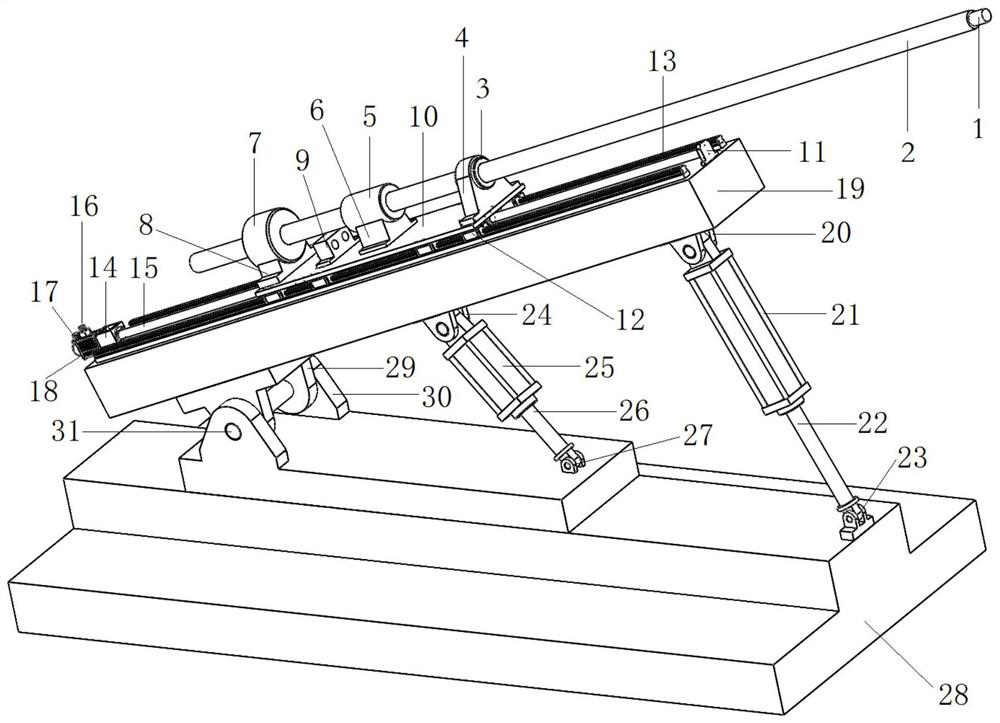

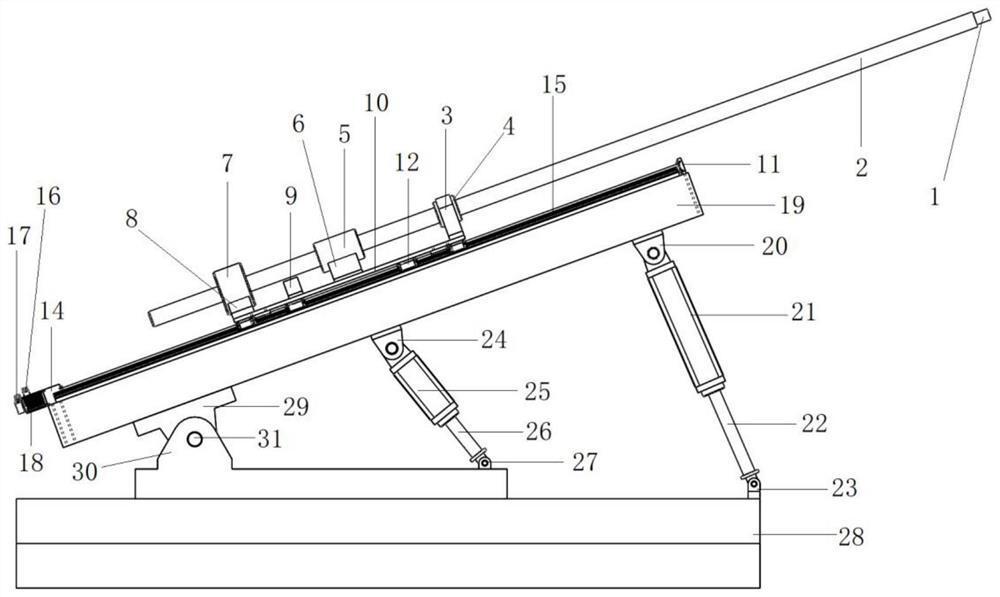

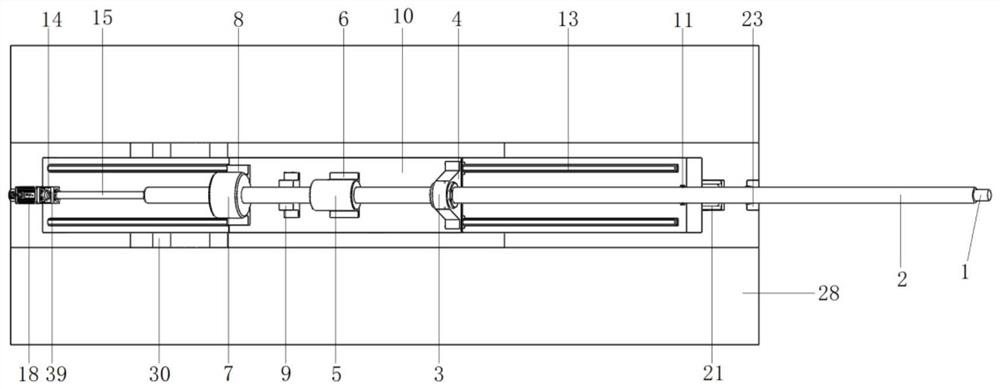

[0033] like Figure 1-Figure 5 As shown, a rock mass integrity drilling device in front of the face of a TBM tunnel according to the present invention includes a drilling assembly, a drilling rig attitude control assembly, a data monitoring assembly, and a TBM drilling rig platform fixing seat.

[0034] like Figure 1-Figure 4As shown, the drilling assembly consists of an alloy drill bit 1, a drill pipe 2, a pallet slider 10, a pipeline 15, a TBM hydraulic input port 16, a hydraulic adapter 35, a hydraulic adapt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com