Integral steel platform formwork equipment for inclined wall construction and construction method of integral steel platform formwork equipment

An integral steel and steel platform technology, applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problem of difficulty in meeting the requirements for safe and efficient construction of inclined walls, poor construction applicability of inclined walls, and existing safety problems. Hidden dangers and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above objects, features and advantages of the present invention more clearly understood, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

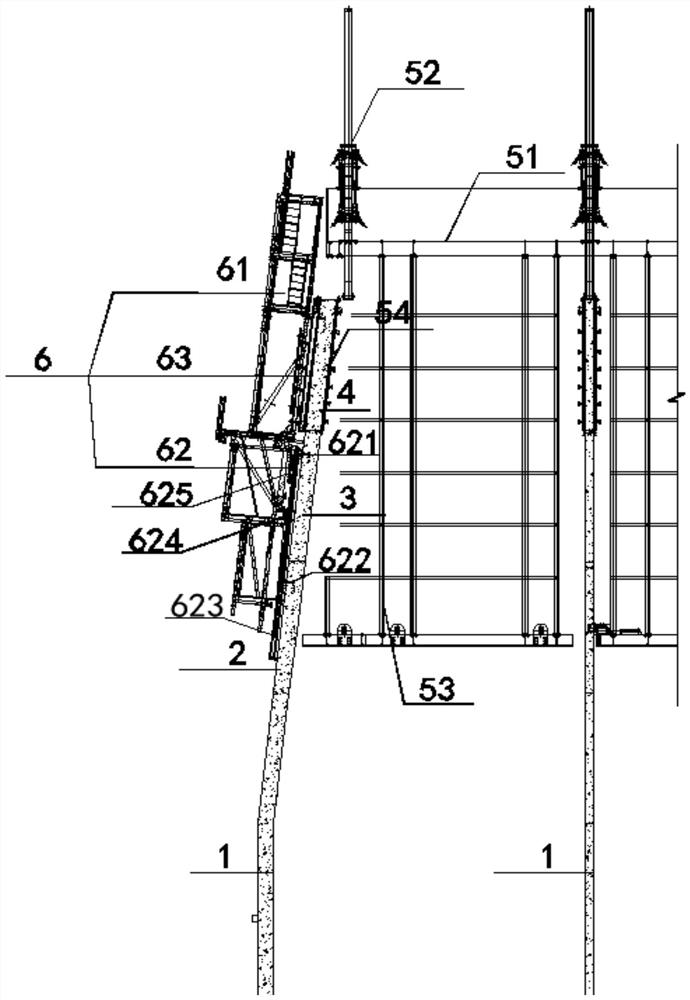

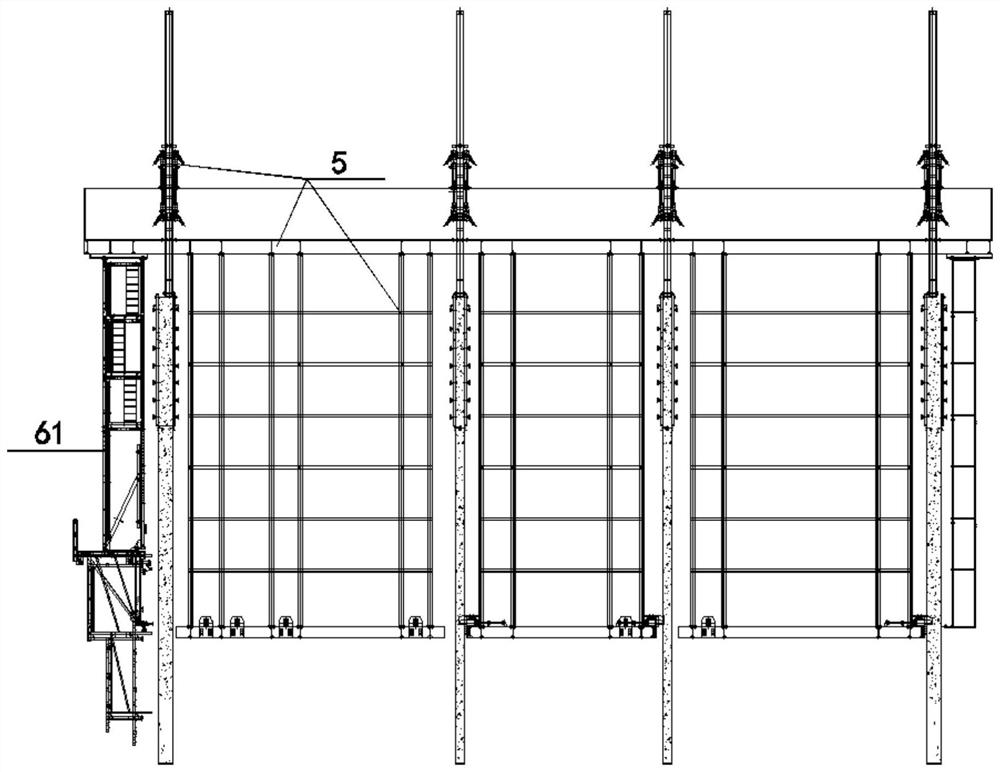

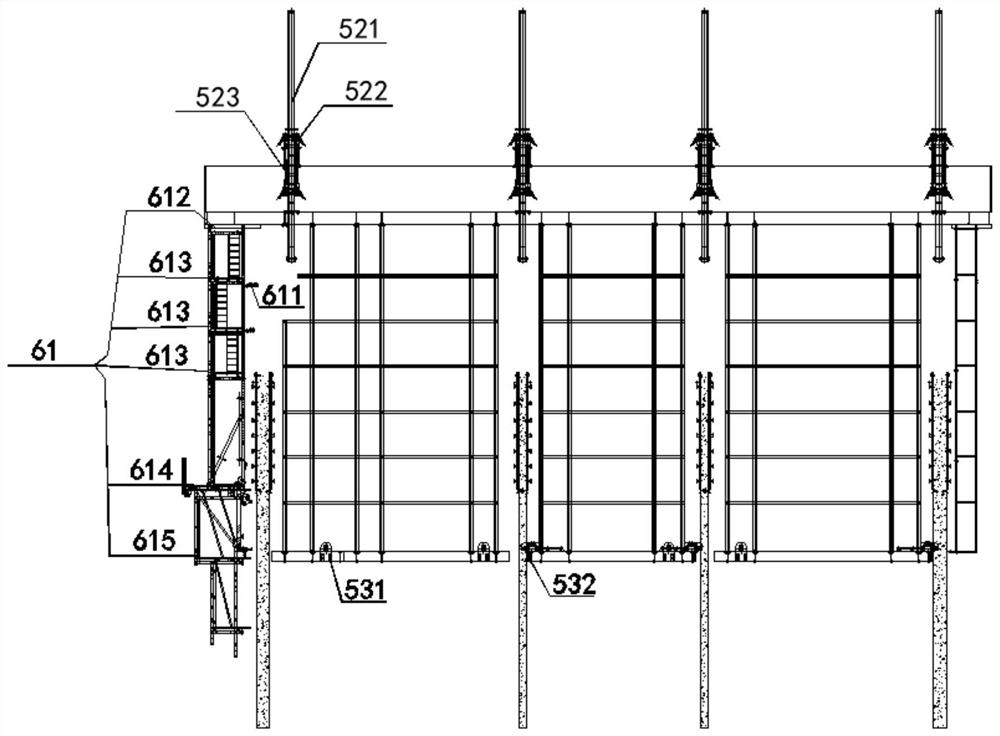

[0034] like Figures 1 to 3As shown, the present invention provides an integral steel platform formwork equipment for inclined wall construction, comprising:

[0035] The main body part 5 includes: a steel platform system 51, a cylinder frame support system 53, a steel column climbing system 52, and a main formwork system 54, wherein the steel column climbing system 52 is located on the top of the inclined wall to be constructed, and the steel platform system 51 is connected to the Under the steel column climbing system 52 , the cylinder frame support system 53 is fixed to the lower part of the steel platform system 51 by bolts, and the cylinder frame support system 53 is supported by the hydraulic telescopic steel corbel 531 lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com