Cylinder frame support type integral steel platform suitable for inclined wall construction and construction method thereof

A steel platform and supporting technology, which is applied in the direction of formwork/formwork/work frame, scaffolding for building structure support, building structure support, etc., can solve problems such as inefficient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

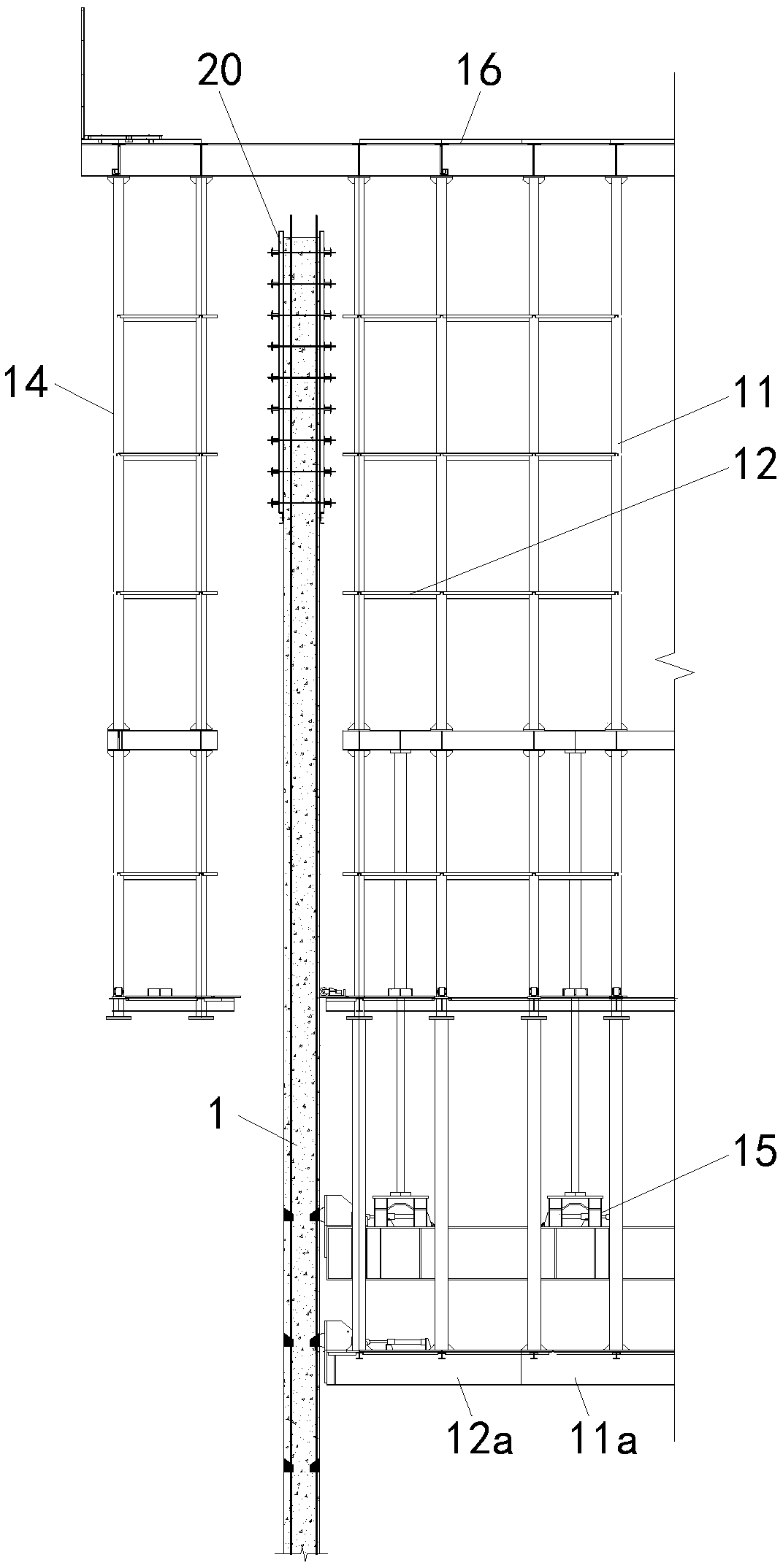

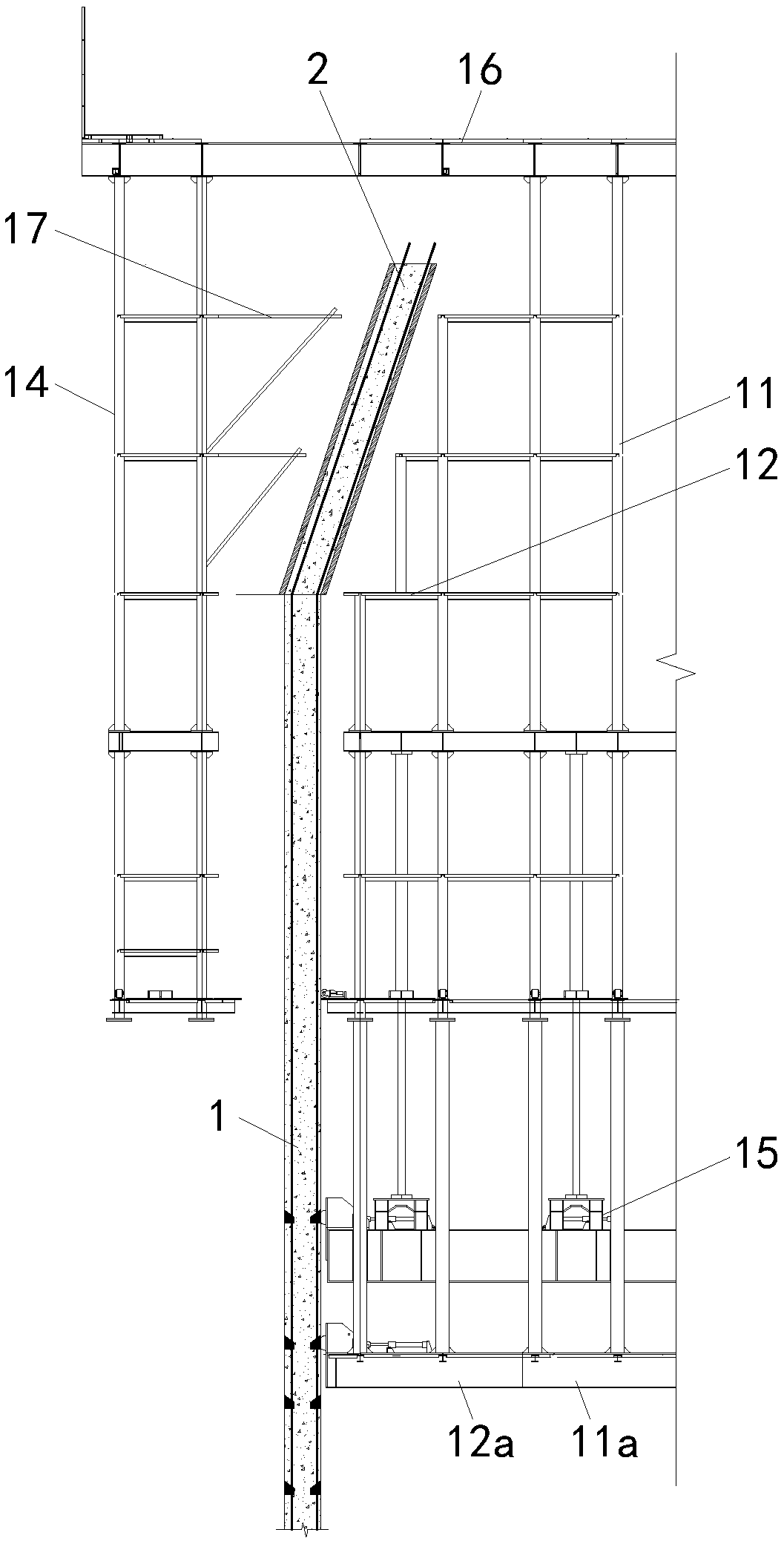

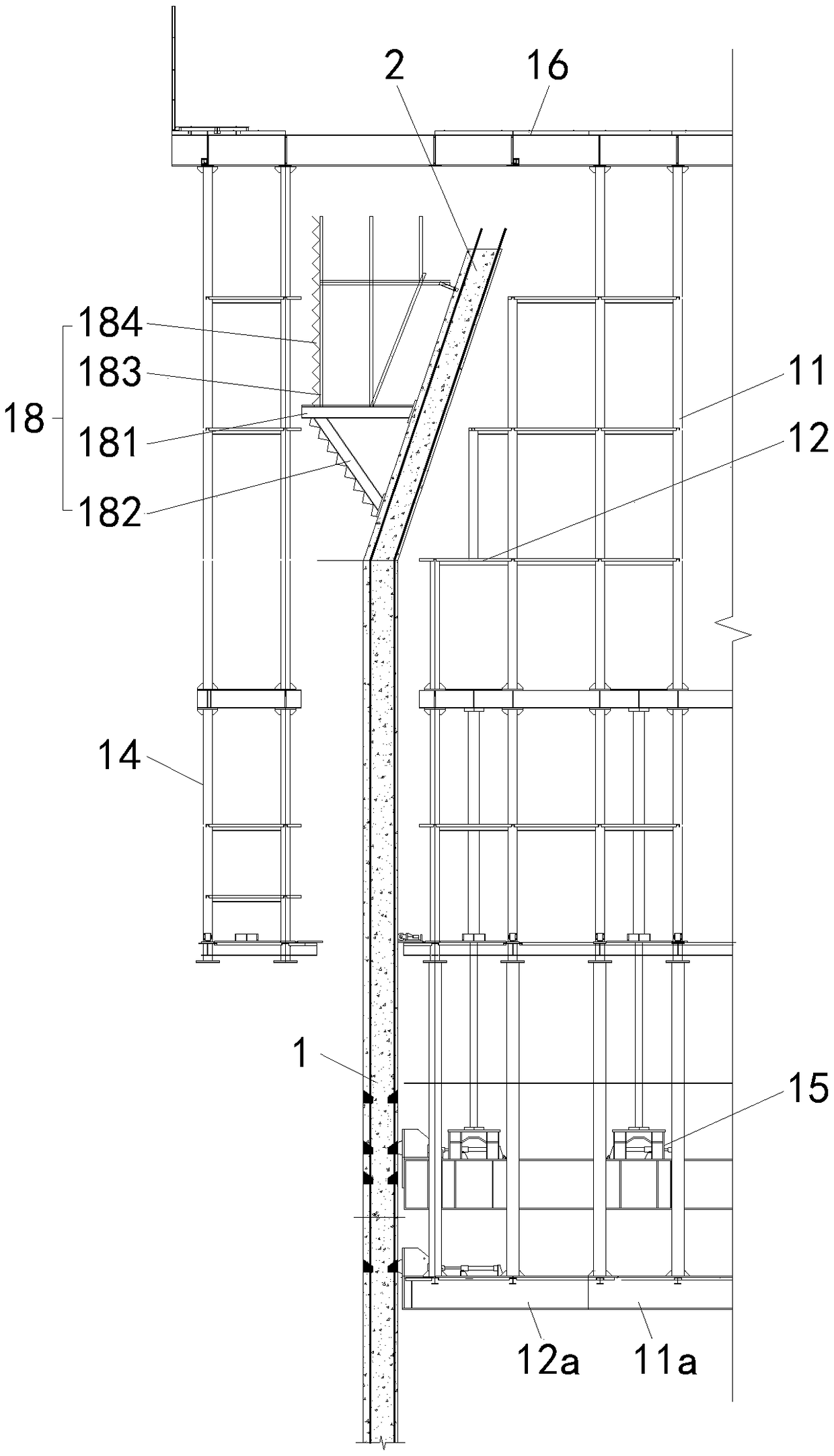

[0032] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be noted that, the accompanying drawings are all in a very simplified form and in inaccurate scales, and are only used to facilitate and clearly assist the purpose of explaining the embodiments of the present invention. For the convenience of description, the "upper" and "lower" described below are consistent with the upper and lower directions of the drawings, but this cannot be a limitation of the technical solution of the present invention.

[0033]The core tube shear wall of this embodiment has a retractable structure, that is, it consists of two-story oblique walls, a vertical structure 1 located below the oblique wall, and a vertical structure located above the oblique wall. Structure 2 and 3 are connected together, and the following is combined Figure 1 to Figure 11 It is explained that the present invention is suitable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com