Pile casing device for brine stratum mucky soil cast-in-place pile construction

A technology of silty soil and cast-in-situ piles, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as excessive sediment, inconvenient construction, and low bearing capacity, and achieve the effect of eliminating pollution and ensuring construction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

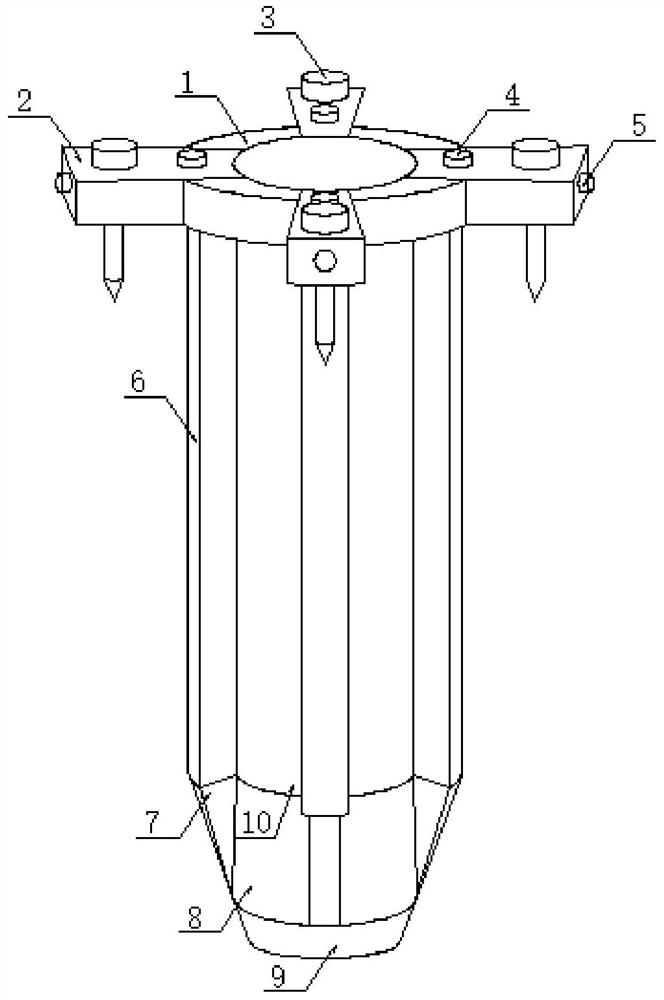

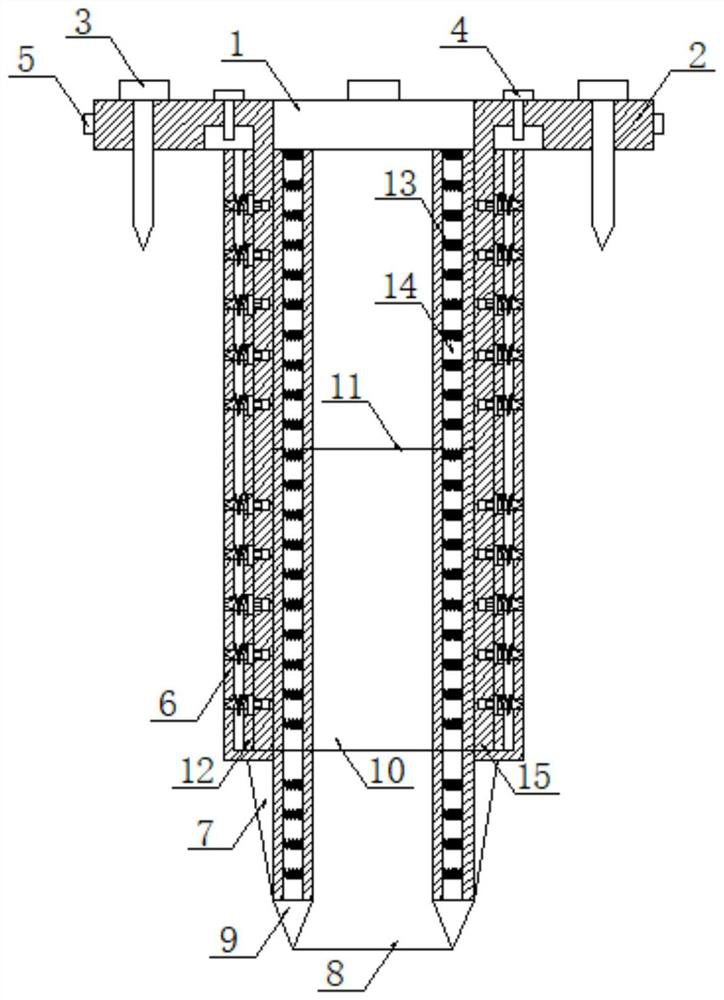

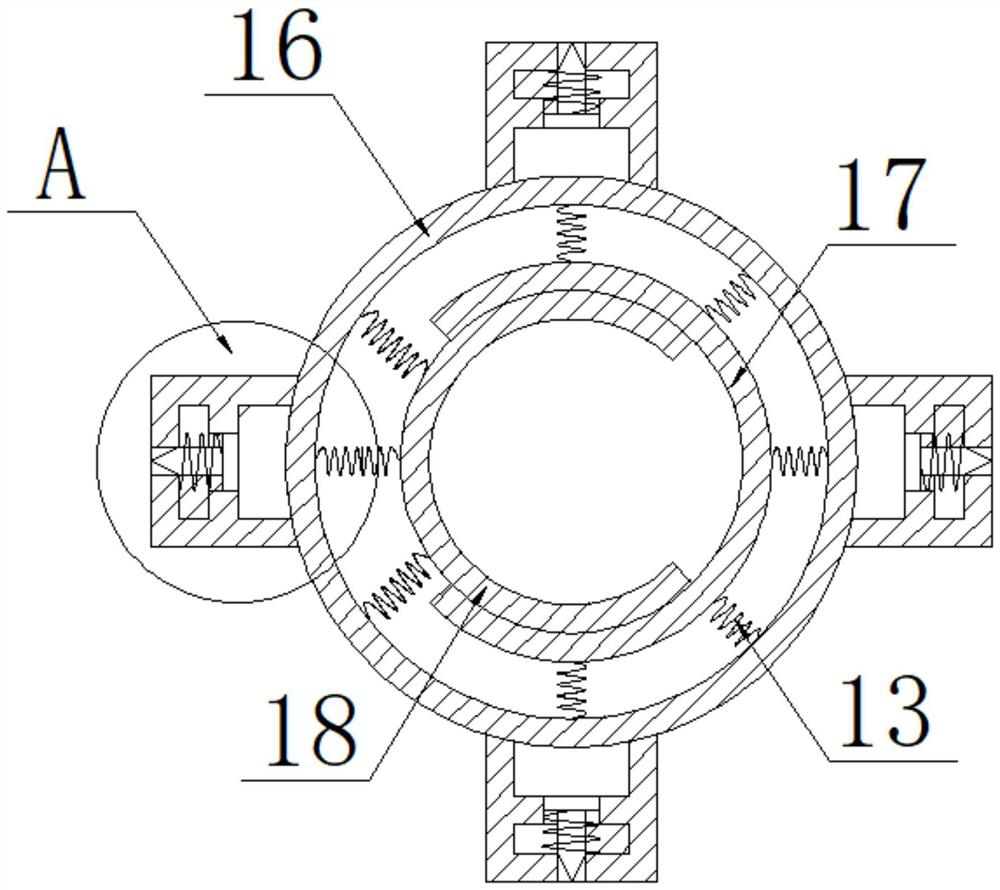

[0038] see Figure 1-8 , the present invention provides a technical solution: a casing device for the construction of silty soil grouting piles in brine formations, comprising a casing head 1, a fixed horizontal plate 2 and an outer casing body 16, the upper surface of the casing head 1 is fixedly connected with The horizontal plate 2 is fixed, and the lower surface of the casing head 1 is fixedly connected with an outer casing 16, and the outer surface of the outer casing 16 is fixedly provided with reinforcing ribs 6, four of which are arranged, and the outer surface of one side of the reinforcing ribs 6 is fixed A plurality of first through holes 19 are provided, and one side of the first through hole 19 is fixed with a partition plate 12, and a plurality of second through holes 22 are provided on the partition plate 12, and the second through hole 22 is in the same position as the first through hole 19. Correspondingly arranged, one side of the dividing plate 12 is fixedly...

Embodiment 2

[0046] see Figure 1-8 , the present invention provides a technical solution: a casing device for the construction of silty soil grouting piles in brine formations, comprising a casing head 1, a fixed horizontal plate 2 and an outer casing body 16, the upper surface of the casing head 1 is fixedly connected with The horizontal plate 2 is fixed, and the lower surface of the casing head 1 is fixedly connected with an outer casing 16, and the outer surface of the outer casing 16 is fixedly provided with reinforcing ribs 6, four of which are arranged, and the outer surface of one side of the reinforcing ribs 6 is fixed A plurality of first through holes 19 are provided, and one side of the first through hole 19 is fixed with a partition plate 12, and a plurality of second through holes 22 are provided on the partition plate 12, and the second through hole 22 is in the same position as the first through hole 19. Correspondingly arranged, one side of the dividing plate 12 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com