Quick press-in type tubular pile well and application thereof

A press-in type and pipe pile technology, applied in the separation method, construction, filtration and separation, etc., can solve the problems of complex well pipe design, long precipitation time, and high difficulty, so as to improve the efficiency and quality of well completion, and improve the precipitation efficiency , The effect of saving engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

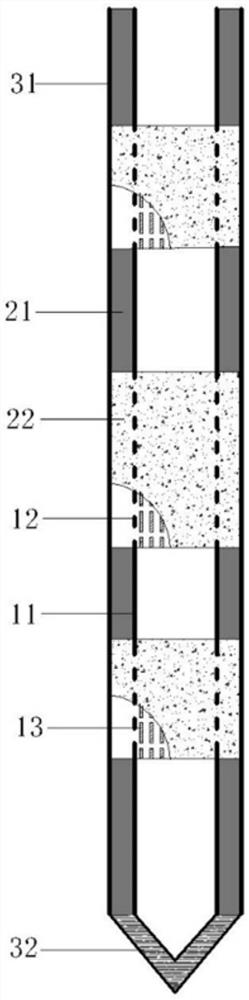

[0038] A quick press-in pipe pile well, such as Figure 1-2 , the pipe pile well includes the well pipe layer, packing layer and outer reinforcement layer arranged from the inside to the outside, as well as the water-resisting layer section and the aquifer layer section for drainage and drainage arranged in a staggered manner. Water layers correspond, and aquifer segments correspond to aquifers in soil.

[0039] The well pipe layer includes a well wall pipe 11 and a water filter pipe 12 which are fixedly connected to each other and play a supporting and diverting role; the well wall pipe 11 is located in the water-resisting layer section, and the water filter pipe 12 is located in the aquifer section. The water filter pipe 12 is provided with a permeable hole 13 for drainage and drainage. The surface of the permeable hole 13 is plugged with a net and sealed with wax to prevent the permeable hole 13 from being destroyed during well formation.

[0040] The packing layer include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com