Synthetic system and method for sludge soil layer deep foundation pit supporting

A deep foundation pit support and comprehensive system technology, applied in the field of comprehensive system of deep foundation pit support in muddy soil, can solve the problem that horizontal steel support is easy to hinder the construction personnel's operation, the ability to resist horizontal load is limited, and the foundation floor cannot be replaced. problems such as bracing, so as to avoid the safety hazards of the enclosure structure, save the amount of steel, and increase the rigidity and bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

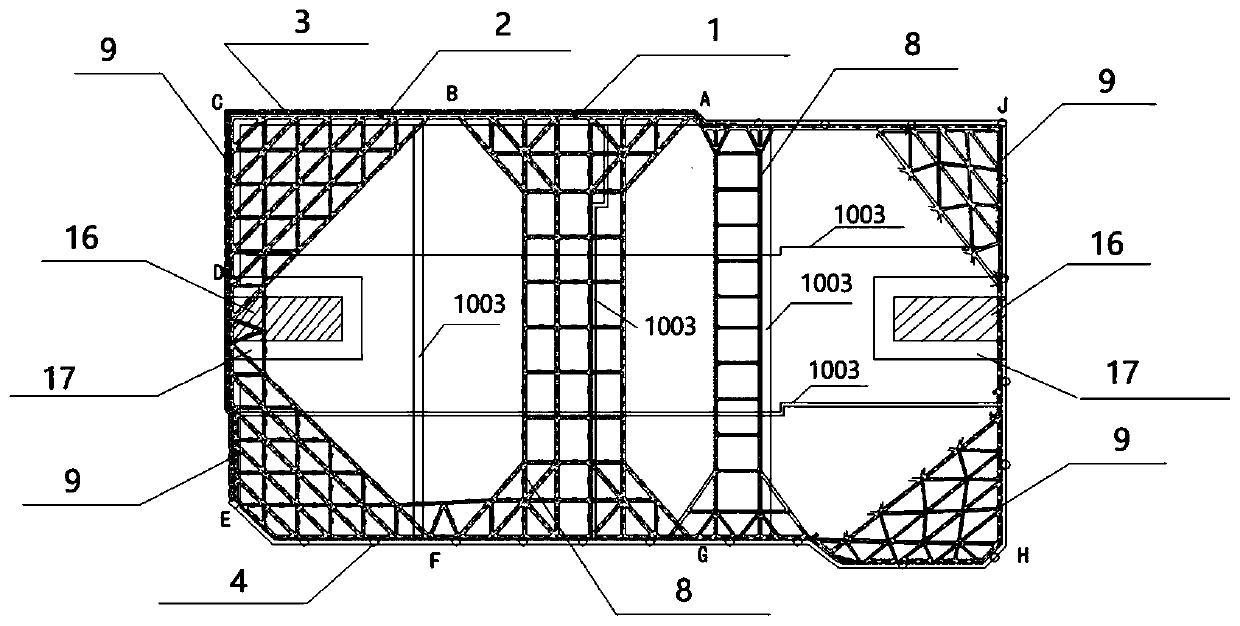

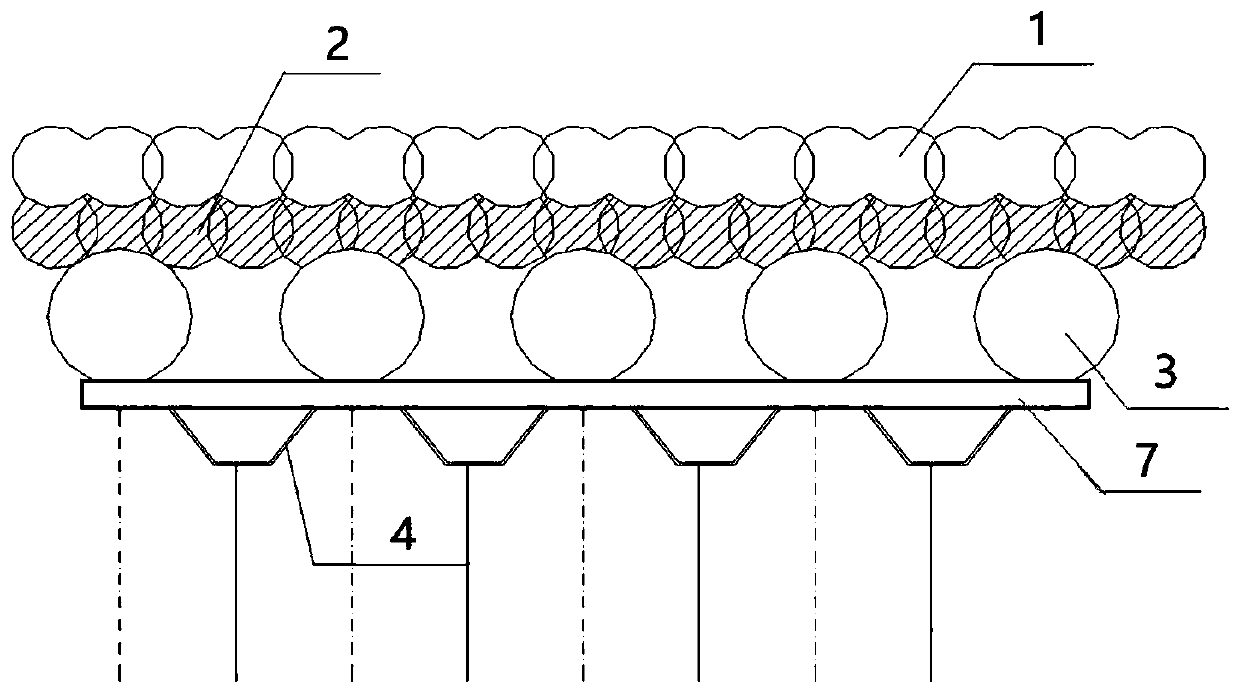

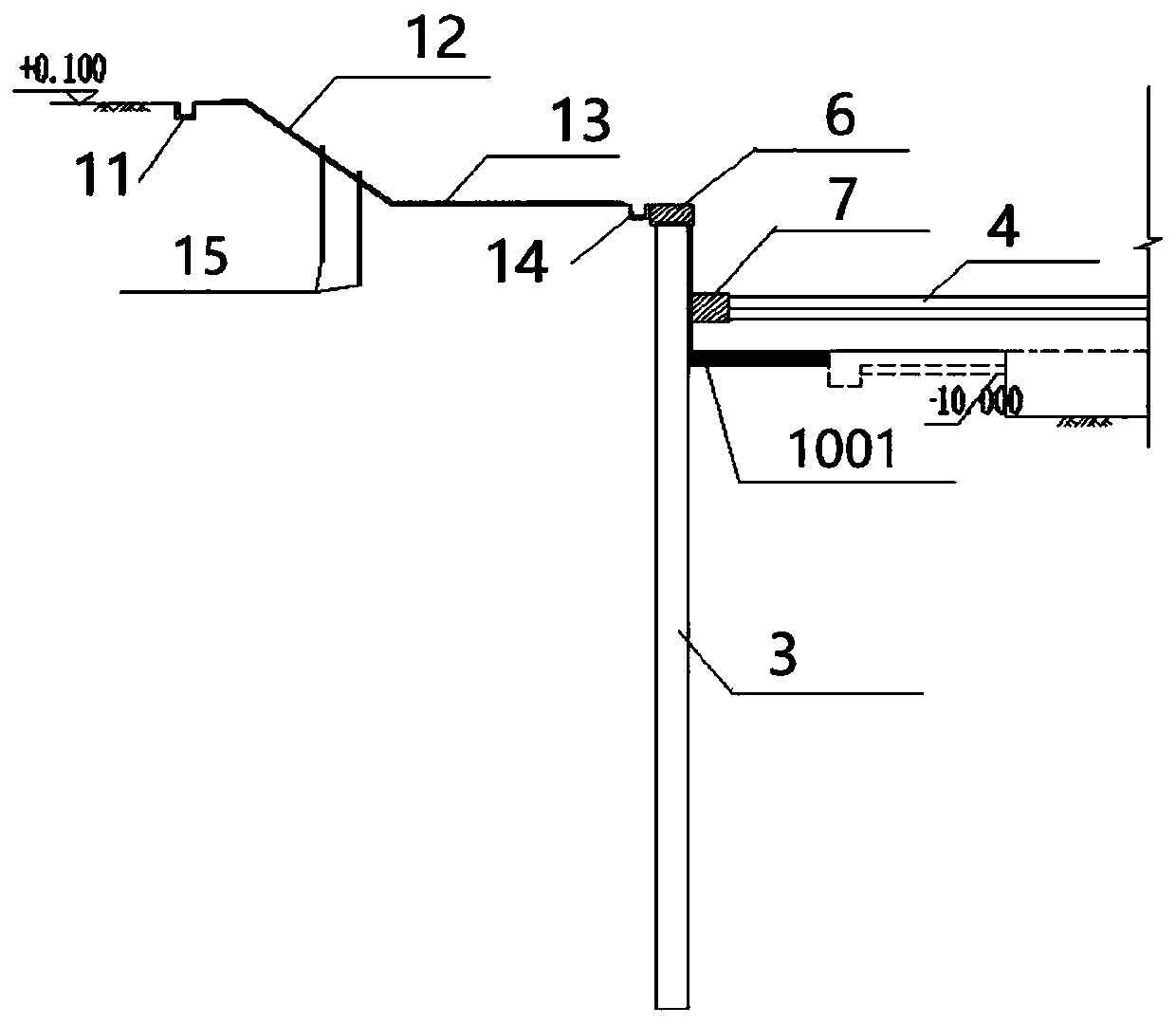

[0029] please see Figure 1-Figure 7 , a comprehensive system for deep foundation pit support in silty soil layer provided by the present invention, including ABCDE silt soil body support area, EFGHJA soft soil body support area, floor layer, ESC-H Larsen pile 4 , Reinforced high-pressure rotary grouting cement-soil pile anchor rod 5, ring-shaped crown beam and waist beam; ABCDE silt soil support area includes biaxial cement mixing pile 1, high-pressure rotary grouting pile 2, punching cast-in-place pile 3; several Biaxial cement mixing piles 1 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com