Deep and thick soft soil deep foundation pit soft soil body pre-reinforcement method

A deep foundation pit and soft soil technology, applied in excavation, soil protection, infrastructure engineering, etc., can solve the problems of uncontrollable upper soft soil deformation and increase construction risks, saving materials, construction time, construction methods, etc. Easy to operate and save construction materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

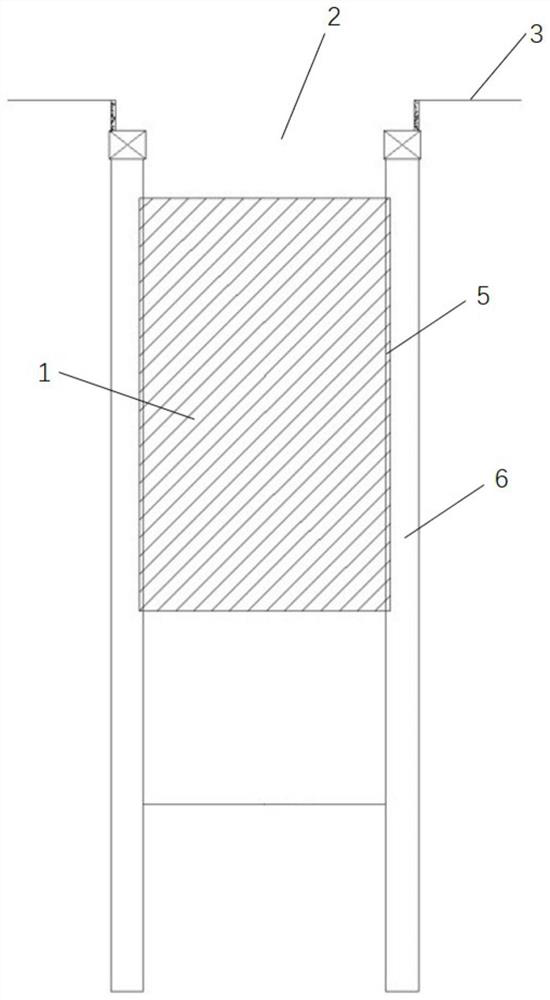

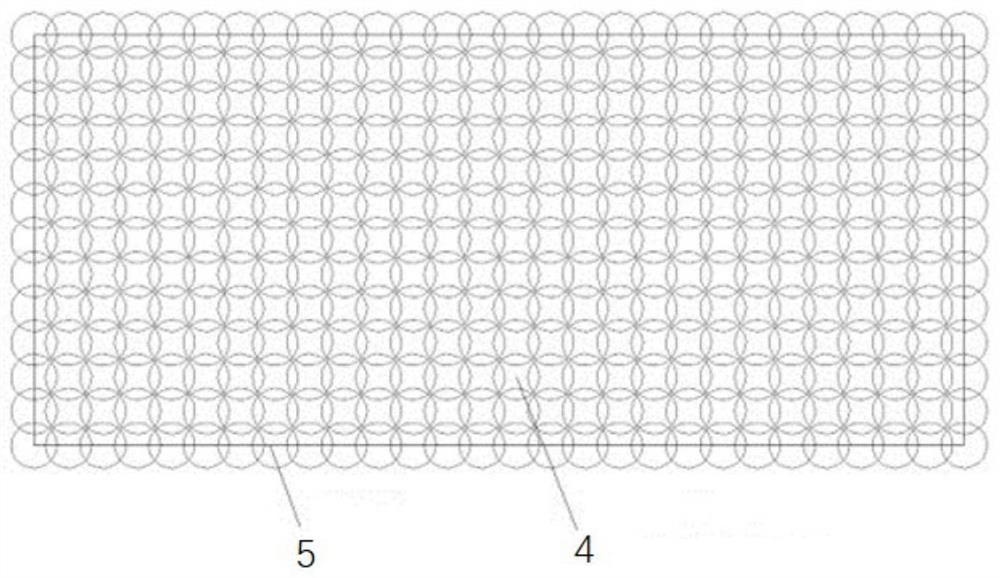

[0042] see figure 1 with figure 2 , the present embodiment adopts the triple tube method high-pressure rotary grouting piles to pre-reinforce the weak soil inside the rectangular deep foundation pit 2, and the reinforced body 1 is composed of a plurality of pile bodies 4, and its structure is a solid belly type. The specific construction method is as follows:

[0043] First construct the foundation pit support structure 6, and then reinforce the soil inside the foundation pit. Pile body 4 adopts triple tube method high-pressure rotary grouting pile, the strength grade of ordinary Portland cement used is 32.5MPa, the water-cement ratio is 0.8, and the amount of cement added to the rotary grouting pile per cubic meter is 450kg; the pile diameter is 0.8m, Arranged in a square, the vertical and horizontal pile spacing is 0.6m, and the interlocking is 0.2m. First construct a single reinforced pile body 4, and then move the construction equipment according to the design spacing ...

Embodiment 2

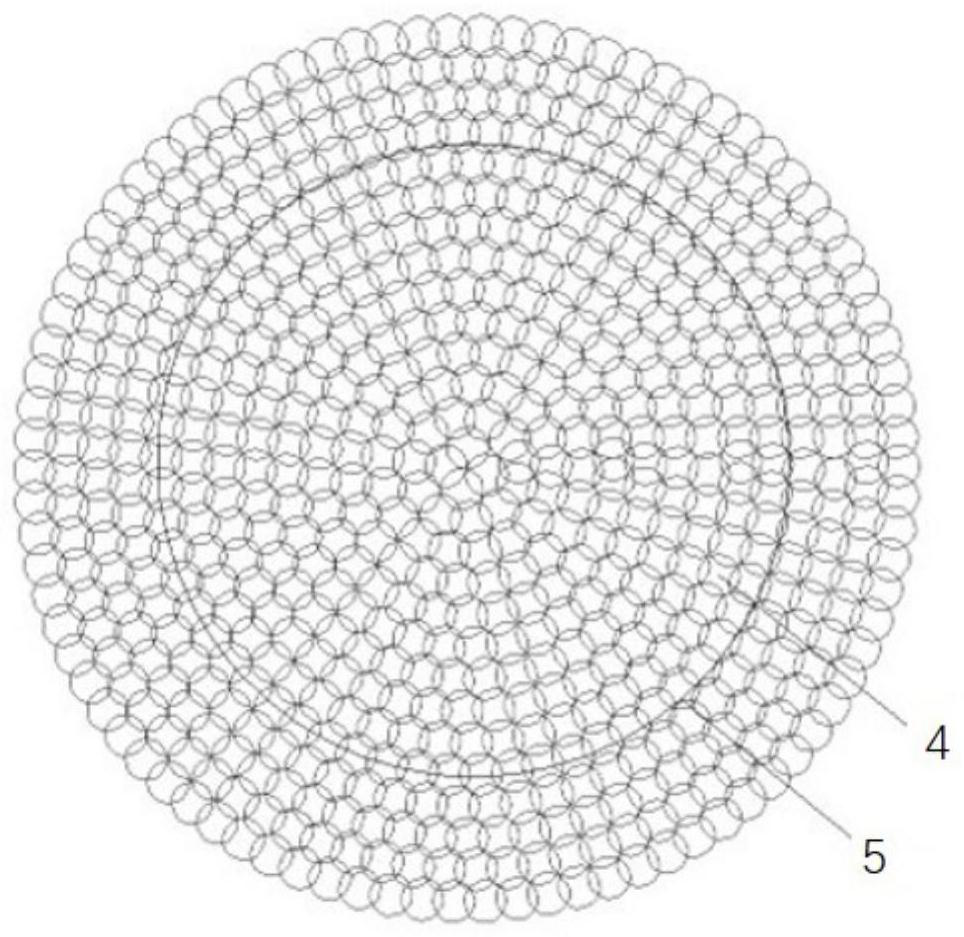

[0045] see figure 1 with image 3 , the present embodiment uses cement-soil mixing piles to pre-reinforce the weak soil inside the circular deep foundation pit 2, and the reinforced body 1 is composed of a plurality of pile bodies 4, and its structure is a solid belly type. The specific construction method is as follows:

[0046] First construct the foundation pit support structure 6, and then reinforce the soil inside the foundation pit. Pile body 4 is a cement-soil mixing pile, the ordinary portland cement strength grade used is 32.5MPa, the water-cement ratio is 0.50, and the amount of cement in the mixing pile per cubic meter is 270kg; The vertical and vertical pile spacings are both 0.4m, and the occlusion is 0.2m. First construct a single reinforced pile body 4, and then move the construction equipment according to the design spacing requirements, construct adjacent pile bodies 4, and construct sequentially along the longitudinal (or horizontal) direction. After cons...

Embodiment 3

[0048] see figure 1 with Figure 4 In this embodiment, MJS construction method piles are used to pre-reinforce the weak soil inside the rectangular deep foundation pit 2, and the reinforced body 1 is composed of a plurality of pile bodies 4, and its structure is a partial displacement type. The specific construction method is as follows:

[0049] First construct the foundation pit support structure 6, and then reinforce the soil inside the foundation pit. Pile body 4 adopts MJS construction method piles, the strength grade of ordinary Portland cement used is 32.5MPa, and the cement mixing amount in each cubic meter of MJS construction method piles is 500kg. The outer side of reinforcement body 1 adopts two rows of continuous interlocking arrangement, the pile diameter is 1m, arranged in a square, the longitudinal and transverse pile spacing is 0.8m, and the interlocking is 0.2m. First construct a single reinforced pile body 4, and then move the construction equipment accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com