Clay court and construction method thereof

A construction method and technology of tennis courts, which can be applied to buildings, roads, pavement, etc., can solve the problems of ball course changes, hidden dangers of sports safety, complex construction, etc., and achieve good shock absorption performance, high professional performance, and good water seepage performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

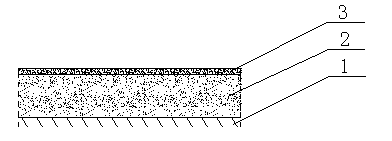

[0044] like figure 1 As shown in the schematic diagram of the structure of the laterite tennis court, it includes the bottom layer of laterite fragments and the surface layer of laterite fine sand laid on the foundation of the field from bottom to top; the foundation of the field is any hard ground foundation or lime soil foundation or elastic mat or semi-elastic carpet.

[0045] The bottom layer of laterite fragments is composed of laterite fragments and elastic particles in a weight ratio of 10:0--10:4, and the binder is bonded with the mixture in a weight ratio of 1:7--15. The laterite fragments are made of volcanic rock, clay Tablets, red sand, and colored sand are crushed by a rock crusher. The particle size of laterite fragments is 3-12 mm, the particle size of elastic particles is 0.5-6 mm, and the thickness of the bottom layer of laterite fragments is 2-10 cm.

[0046] Elastic particles are cold-resistant and high-temperature-resistant polymer elastic particles, inclu...

Embodiment 2

[0049] The construction method of the laterite tennis court described in the above embodiment is as follows: on the basis of the existing field, lay the bottom layer of laterite fragments and the surface layer of laterite fine sand sequentially from bottom to top, and install the field line after the laying is completed.

[0050] Taking the construction of a 1㎡ hard foundation laterite site as an example, the construction technology of the bottom layer of laterite fragments is as follows:

[0051] 1. Foundation treatment: Clean up 1㎡ of cement concrete hard ground, including sundries, oil stains, filling and leveling treatment, pickling treatment after cleaning.

[0052] 2. The volcanic rock is crushed into laterite fragments with a particle size of 10mm by a rock crusher, and 28KG of laterite fragments and 2.8KG of binder are added to the mixer at a weight ratio of 10:1, and stirred evenly.

[0053] 3. Pour the well-mixed laterite fragments and binder mixture into the paver, ...

Embodiment 3

[0061] In this embodiment, the construction of a 1㎡ lime soil foundation site is taken as an example, and the construction technology of the bottom layer of lateritic fragments is as follows:

[0062] 1. Foundation treatment: Clean up the lime soil foundation of 1㎡, including sundries, oil stains, and levelling treatment.

[0063] 2. The clay fired pieces are crushed into laterite fragments with a particle size of 8mm by a rock crusher, and 70KG of laterite fragments are mixed with 10.5KG of elastic particles with a particle size of 0.5mm in a weight ratio of 10:1.5, and then glued with 5.5KG The binder and the above mixture are added to the mixer at a weight ratio of 1:15, and stirred evenly, wherein the elastic particles are PE polyethylene particles.

[0064] 3. Pour the mixture of laterite fragments, elastic particles and binder evenly mixed according to the weight ratio into the paver, and spread it on the lime soil foundation through the paver, spread it according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com