Storage tank for large-scale fused salt energy storage

A large-scale, molten salt technology, applied in tank trucks, large containers, containers, etc., can solve the problems of complex systems, poor reliability, increased failure points, small tank volume, etc., to save tank material costs, reduce failure points, System simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

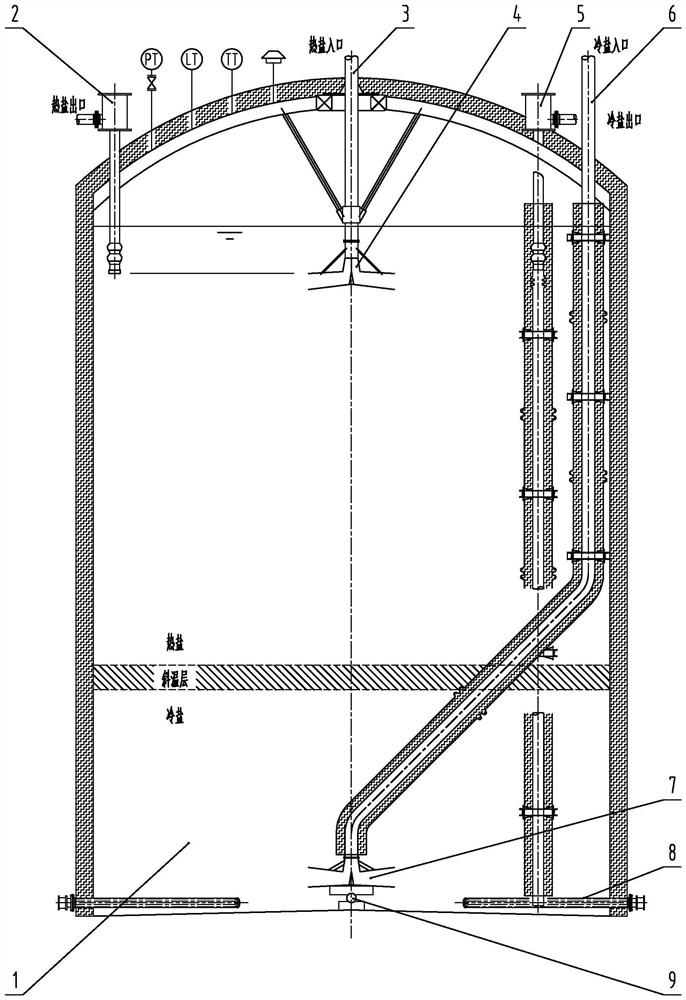

[0036] DETAILED DESCRIPTION One: Combination figure 1 The present embodiment described embodiment, the embodiment of the present embodiment for a large-scale tank molten salt storage tank 1 includes a heat pump 2 salts, salts heat pipe system 3, a hot plate 4 cloths salt, cold saline pumps 5, 6 cold saline piping system, the cold plate salt cloths 7, the electric heater 8, the cold salt cloth supporting unit 9;

[0037] Roof body 1 dome is a spherical cap, on top of the tank body 1 is provided with pressure meters, level meters, temperature meter, and a safety relief unit heat pump salts, salts heat pipe system, the pump and cold saline cold saline pipe system, the pump and the hot salt disposed close to the tank wall, which inlet is provided in a position near the liquid level inside the tank, and heat pipe system disposed salt tank top center position, the outlet of a hot plate is connected cloths salt, cold saline a pump disposed close to the tank wall, that the suction tube in...

specific Embodiment approach 2

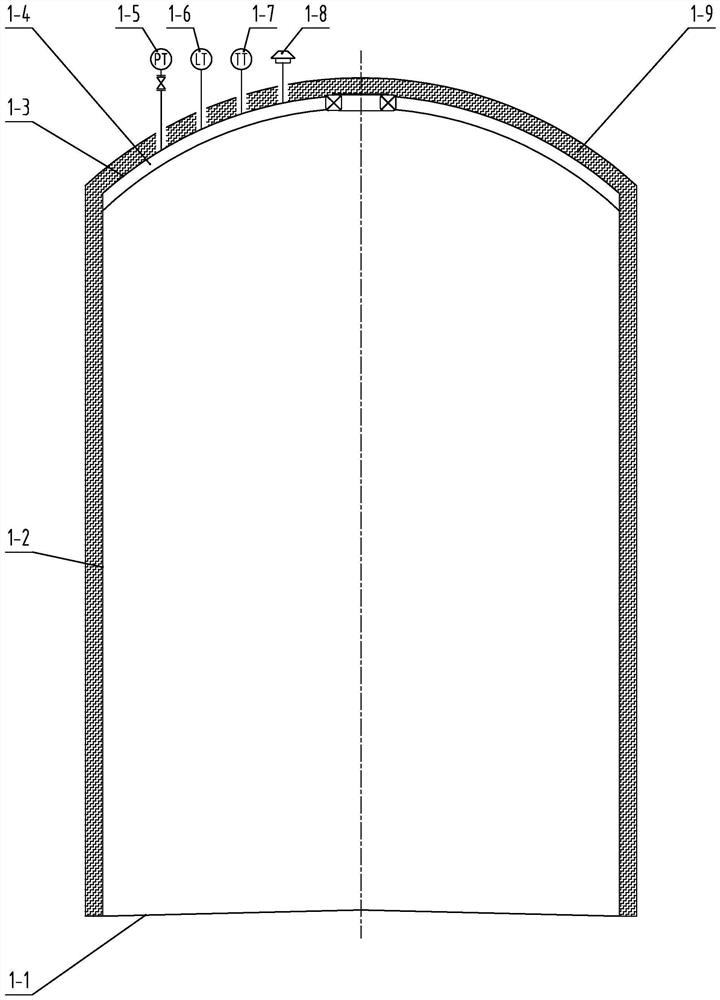

[0043] DETAILED DESCRIPTION 2: Combination figure 2 The present embodiment described embodiment, the present embodiment is further limited to specific embodiments of the tank according to a present embodiment one embodiment of the molten salt storage tank for large-scale, the can body 1 1-1 comprises a tank bottom, the tank wall 1-2, 1-3 roof, roof steel support 1-4, pressure meters 1-5, 1-6 level meter, temperature meter 1-7, safety relief means 1-8 and 1-9 tank insulation means, the upper portion of the tank bottom welded 1-1 1-2 tank wall, the tank wall welded upper roof 1-2 1-3, 1-4 tank top outer edge of the steel support welding the interior tank walls 1-2, an upper portion of the lower tank top surface weld 1-3, 1-5 equipped with a pressure meter, a liquid level meter roof 1-3 1-6 1-7 temperature meter, safety relief device 1-8, 1-3 and 1-2 outside the tank wall provided with roof tank insulation means 1-9

specific Embodiment approach 3

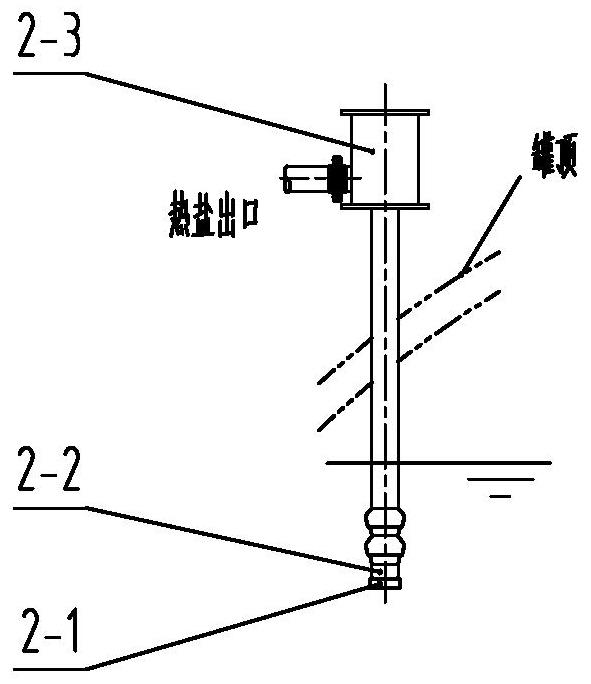

[0044] Specific Embodiment 3: Combination image 3 The present embodiment described embodiment, the present embodiment is further limited to specific embodiments of the tank according to a present embodiment the one storage tank for molten mass, said heat pump salts 2 comprises a suction pipe heat salts 2-1, 2-2, and a power head means 2-3, 2-3 power means connected to one end of the pump head 2-2, the other end of the salts of the suction pipe and the heat pump head 2-2 2-1 connected to the top of the pump head is arranged close to a position near the liquid level, and thus without a long shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com