Frame structure for bridge type and door type combination type crane

A frame structure and combined technology, which is applied in the direction of walking bridge cranes, cranes, bottom support structures, etc., can solve problems such as weak wind resistance, earthquake resistance, poor coordination, and large working blind areas, so as to improve wind resistance and The effect of earthquake resistance, low manufacturing cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

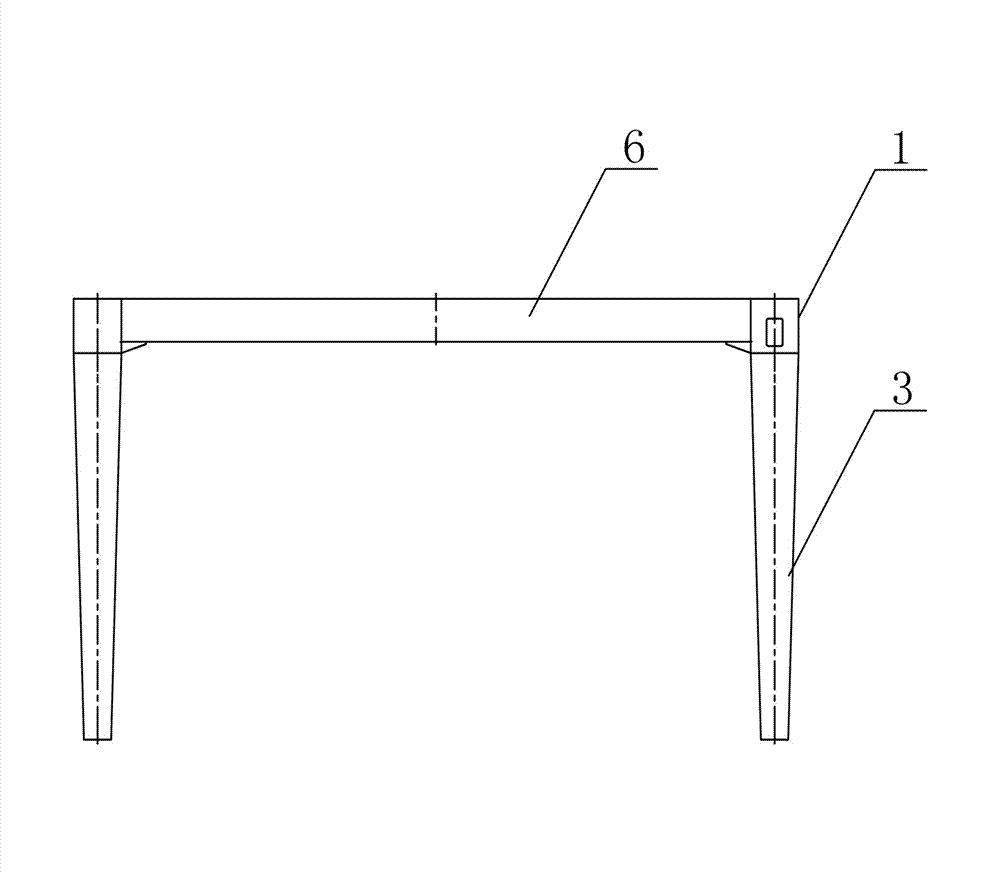

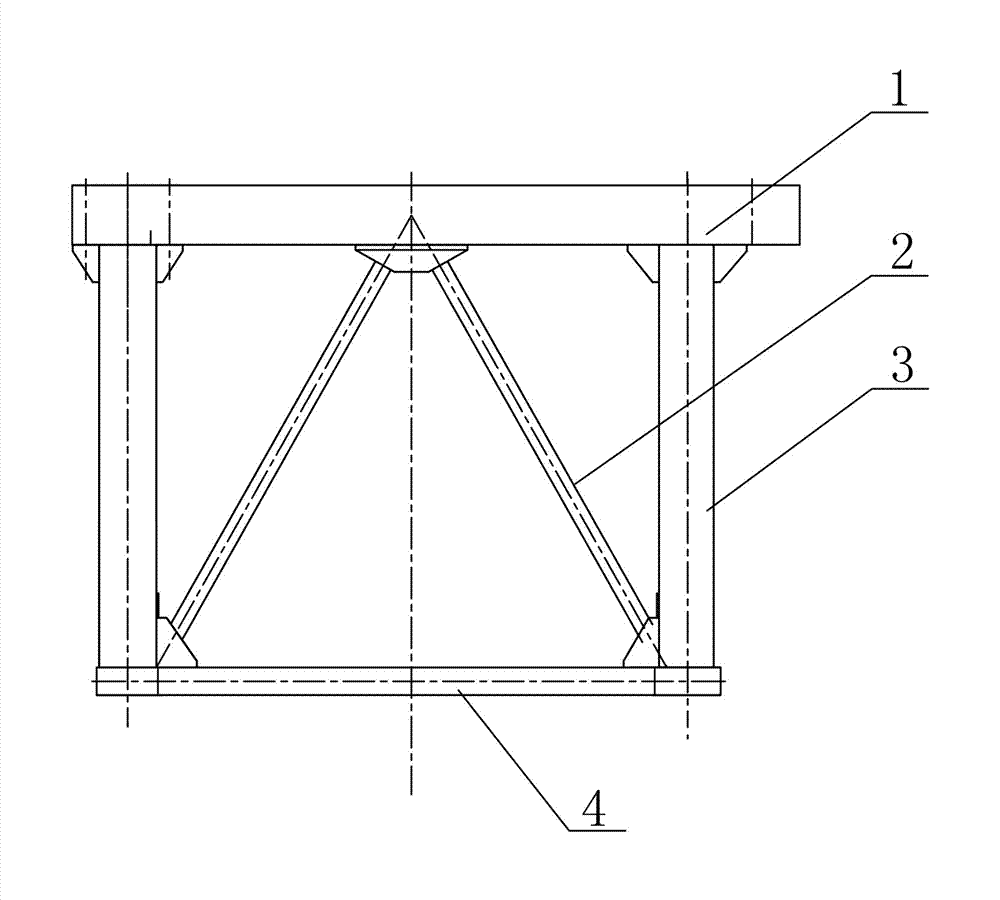

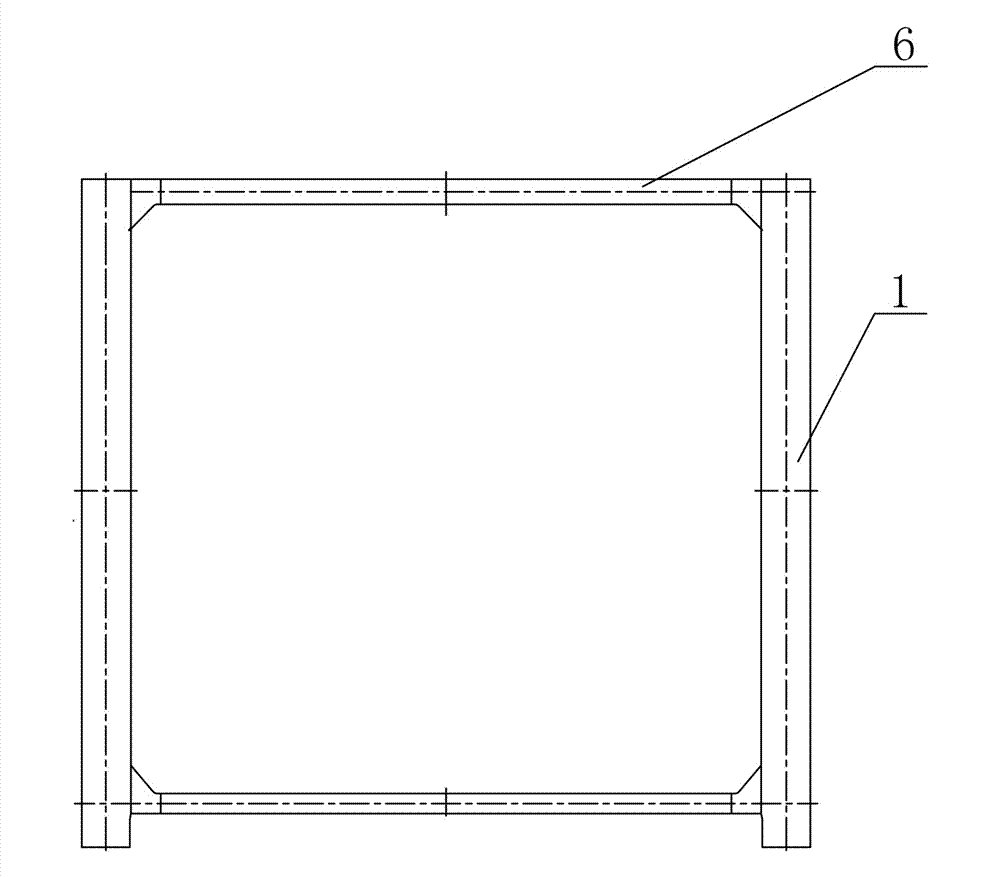

[0012] See attached figure 1 ~ attached image 3 , the present invention is welded by rail beam 1, oblique support 2, column leg 3, lower beam 4 and connection beam 6, described rail beam 1 and lower beam 4 are welded with two column legs 3 to form a side frame, and oblique support 2 is formed by welding The triangle is fixedly arranged between the track beam 1 and the lower beam 4, and the frame on both sides is welded by two connecting beams 6 to form a door frame-shaped steel structure; the track beam 1 and the connecting beam 6 are welded to form an upper plane frame; the track beam 1 is A box-shaped beam, which is provided with a working channel and a lighting system; the column leg 3 is a box-shaped column structure, and an escalator or a manned elevator connected with the track beam 1 is provided inside; the two ends of the inclined support 2 are provided with A connecting plate 8 is welded with the track beam 1 and the lower beam 4.

[0013] See attached Figure 4 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com