Machining process method of special machine for large stay rings

A technology of processing technology and process method, applied in mechanical equipment, engine components, engine manufacturing, etc., can solve problems such as inability to implement and do not have processing conditions, and achieve the effect of ensuring processing quality, flexible relocation, and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A special machine processing method for a large seat ring: the processing method includes the following steps:

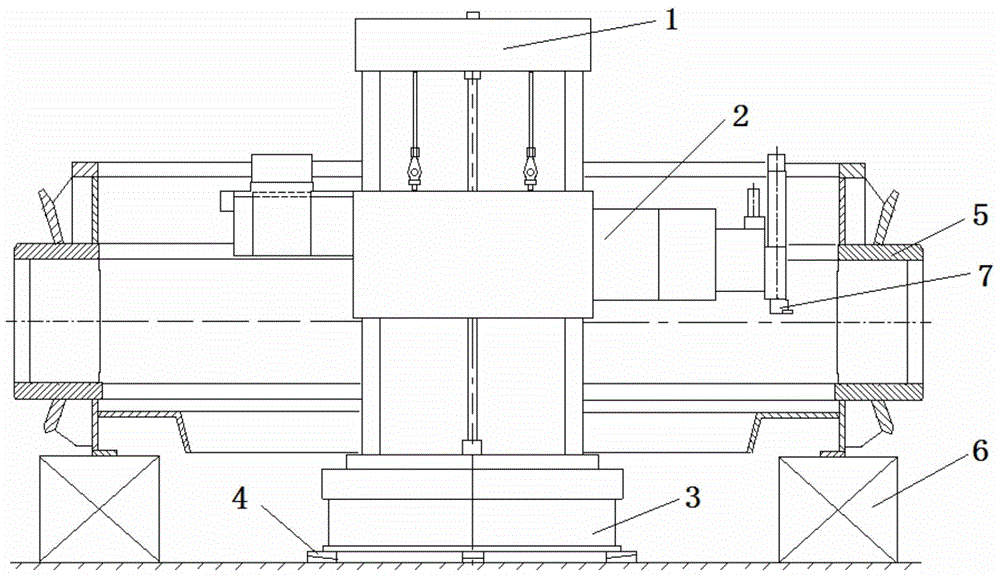

[0023] (1) if figure 1 As shown in the figure, a movable CNC seat ring processing machine is adopted, and the main part of the equipment includes a workbench 3, a column 1, a beam 2, and a tool holder 7;

[0024] (2) The rotating workbench of the equipment is installed on the assembly platform, and the workbench is leveled on the assembly platform with adjustable pad iron 4;

[0025] (3) Hang the split seat ring to the height of the machining stroke range of the machine tool, and on the support of the tooling, form the split seat ring 5 on the square box 6 to form a full circle;

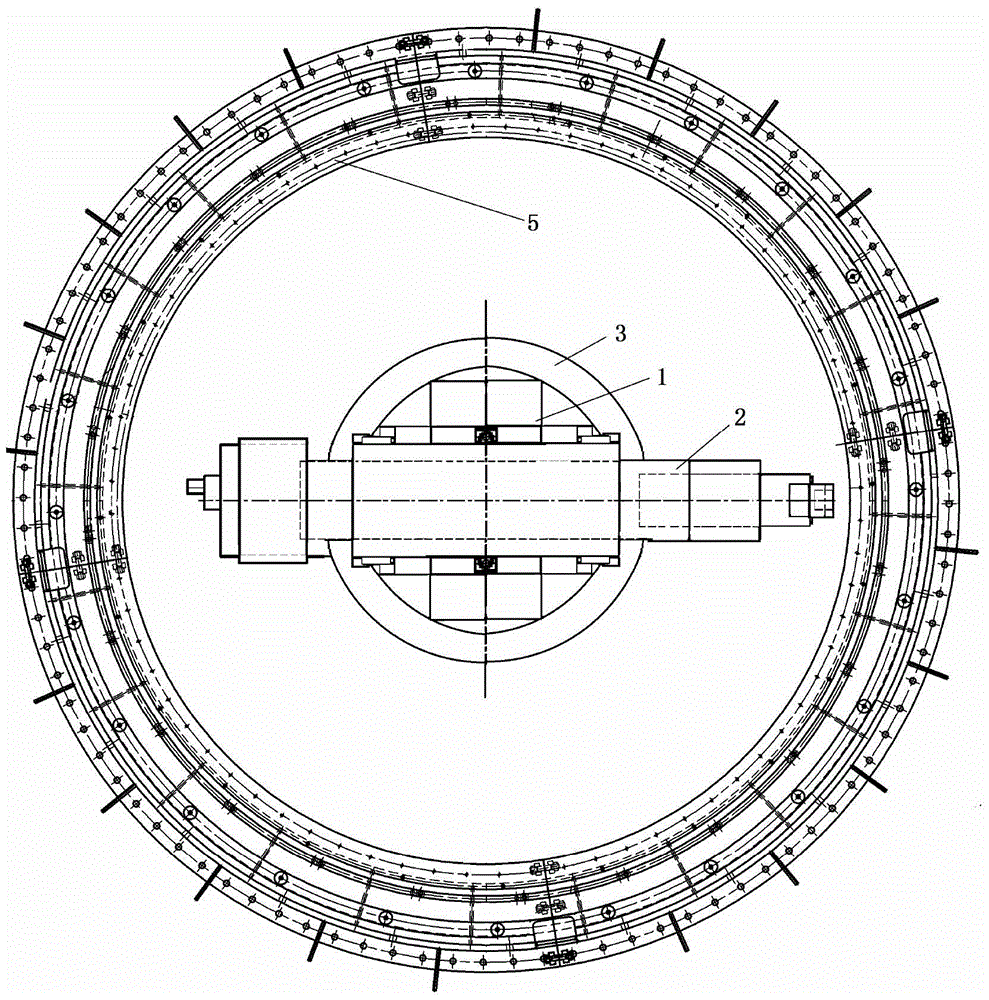

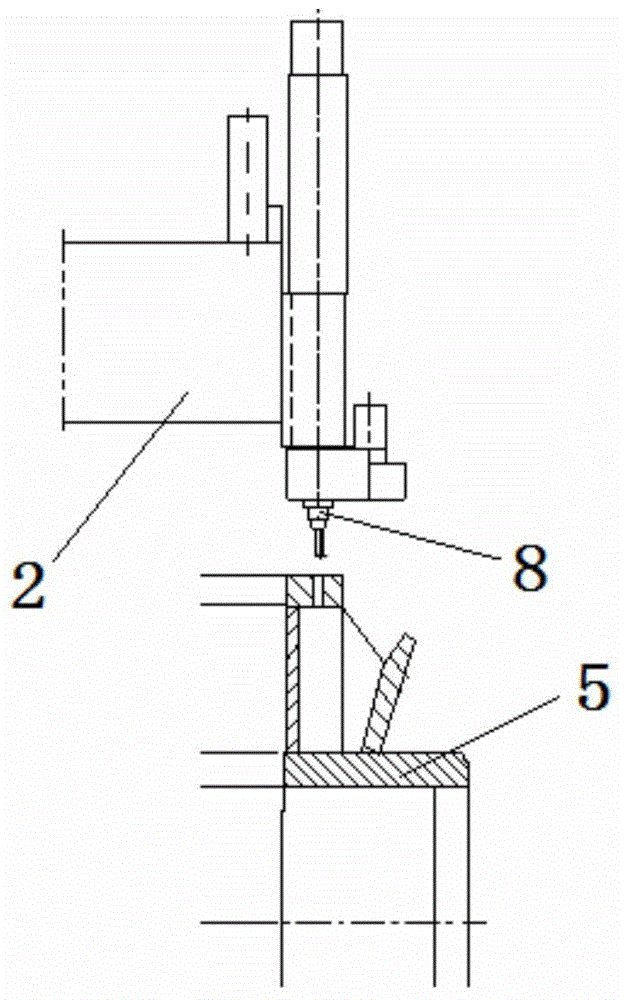

[0026] (4) Adjust machine tool equipment, such as figure 2 As shown, adjust and align according to the existing benchmark on the seat ring 5 to ensure that the equipment is concentric with the seat ring;

[0027] (5) hoisting equipment column 1 and beam 2, tool holder 7 assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com