Method for dismantling discarded jacket through air bags

A jacket and airbag technology, which is applied in the field of offshore oil engineering, can solve problems such as difficulty in pre-selecting the floating crane with lifting capacity, uncertainty of the mud adsorption force, and structural damage to the floating hook, etc., to reduce the risk of offshore construction, The effect of avoiding hoisting risks and reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention adopts following steps:

[0034] Step 1: Preparations for dismantling the discarded jacket 6

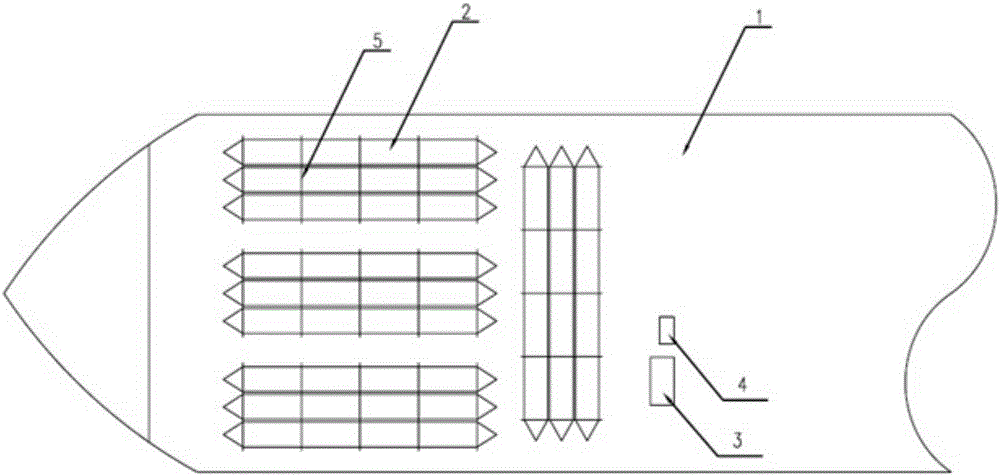

[0035] One, such as figure 1 As shown, the airbag group 2 and the charging and discharging control system are arranged on the stern or bow deck of the workboat 1. The workboat 1 of this embodiment is a tugboat.

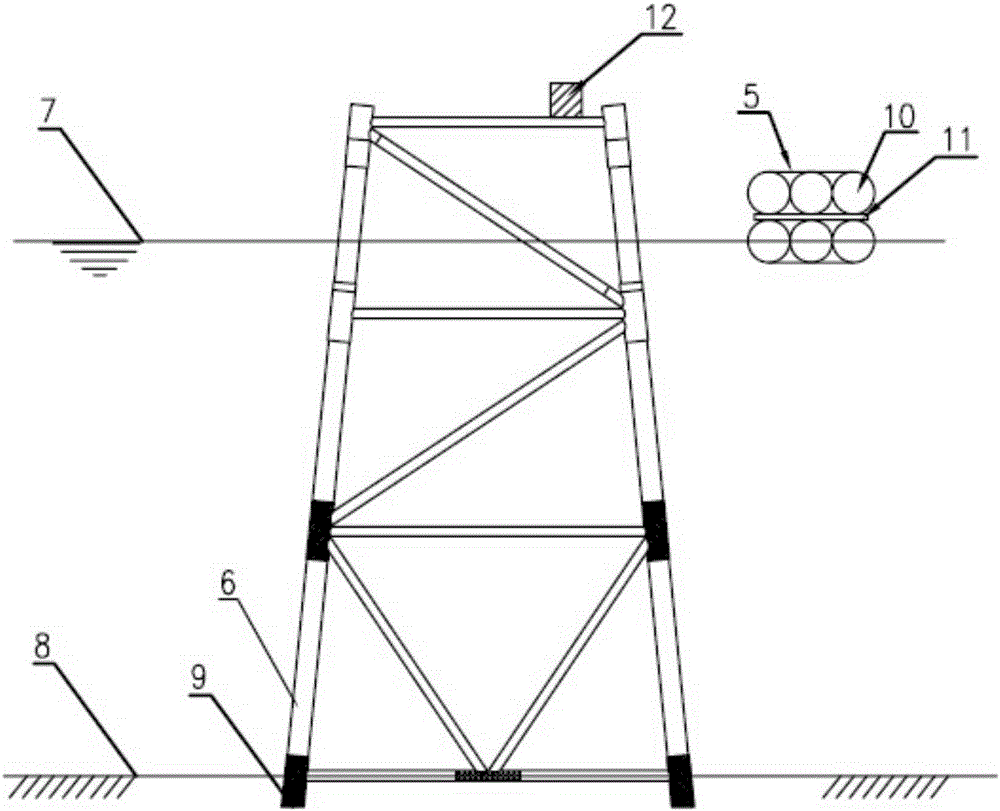

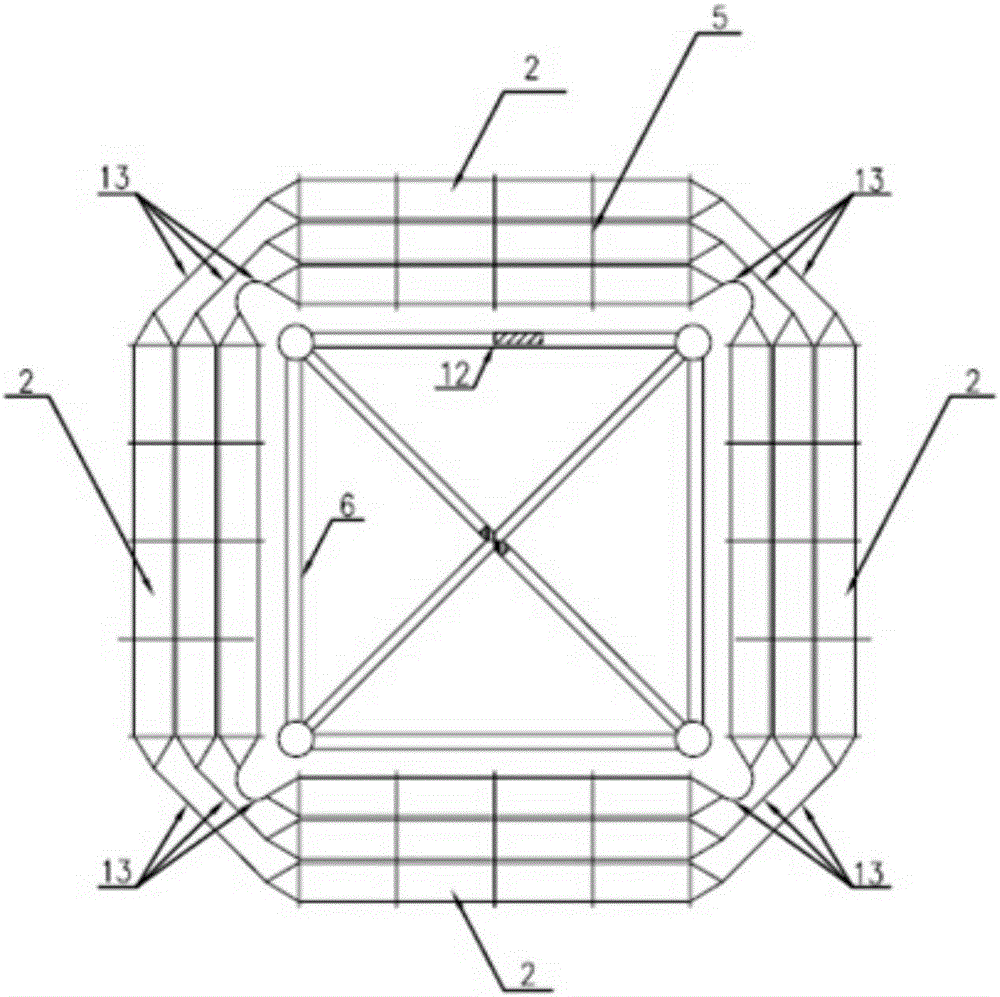

[0036] Two, such as figure 2 As shown, the stern or bow of the workboat 1 is placed close to the abandoned jacket 6 by using the dynamic positioning system arranged on the workboat 1; and the local control panel 12 in the inflation and deflation control system is installed on the abandoned jacket 6 top; after determining that the sea weather and climate window is suitable for sea operations, start the dismantling operation of the jacket 6 abandoned at sea, and after inflating the first air bag group 2 in the air bag buoyancy unit 10, it is launched and floats on the water level 7.

[0037] 3. Before starting the dismantling operation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com