Construction method for replacing disc type support with rail transit plate type support

A technology for rail transit and construction methods, applied in bridge parts, bridge erection/assembly, bridge maintenance, etc., can solve problems such as inability to complete synchronous jacking, replacement of pads, traffic interruption, and affecting the normal operation of lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Take a certain urban rail transit line as an example for construction. The skylight point is from 00:00 to 4:00 every day, and the railway line needs to be in normal operation during the day.

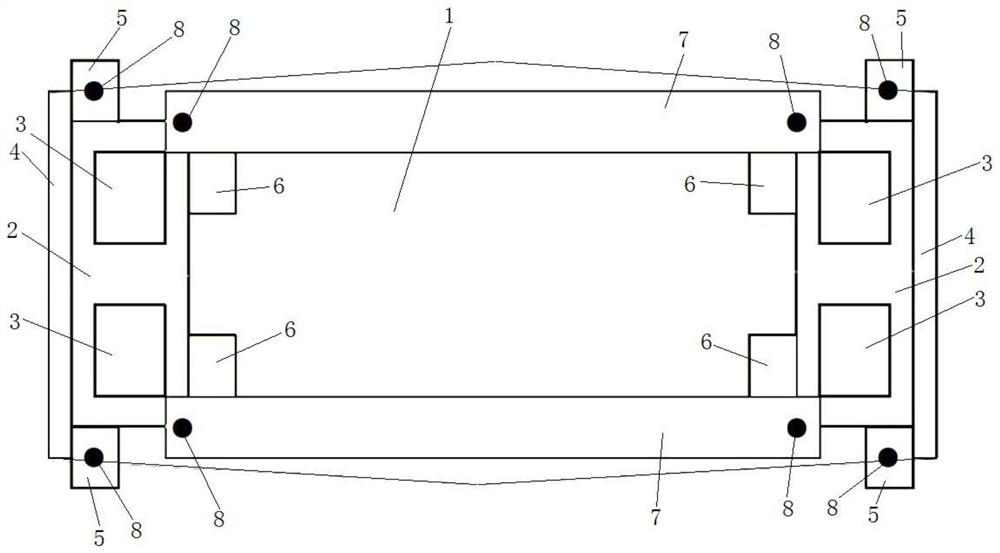

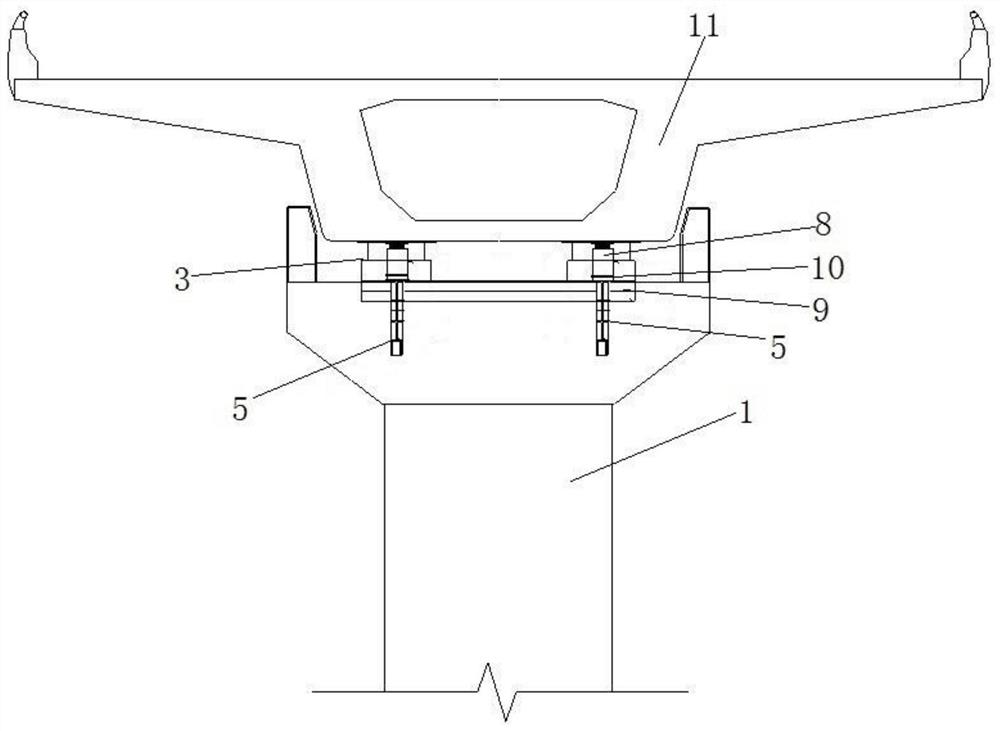

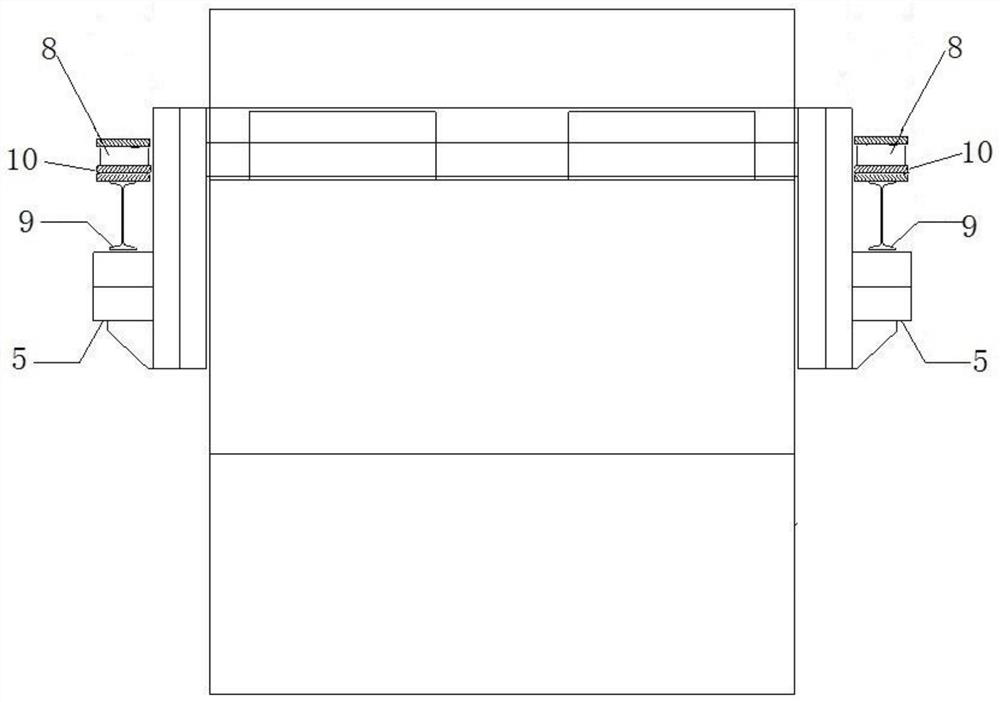

[0048] A construction method for replacing a disc-type bearing with a rail transit slab-type bearing, which includes the following four stages in sequence: a preparation stage, a first jacking stage, a pad stone replacement stage, and a second jacking stage; wherein, the preparation stage and the pad stone replacement stage is completed in the non-skylight point, and the first jacking stage and the second jacking stage are completed in the skylight point;

[0049] Both the first jacking stage and the second jacking stage adopt the construction method of longitudinal split piers and horizontal synchronous jacking beams, and both include the release of the upper restraint force, the overall jacking, and the release of the upper restraint force. Steps for recovery, data acquisition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com