Roadbed karst collapse comprehensive renovation method

A karst collapse and roadbed technology, applied in the direction of roads, infrastructure engineering, buildings, etc., can solve the problems of low construction cost, short period and long period, and achieve the effect of low construction cost, remarkable effect and short period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

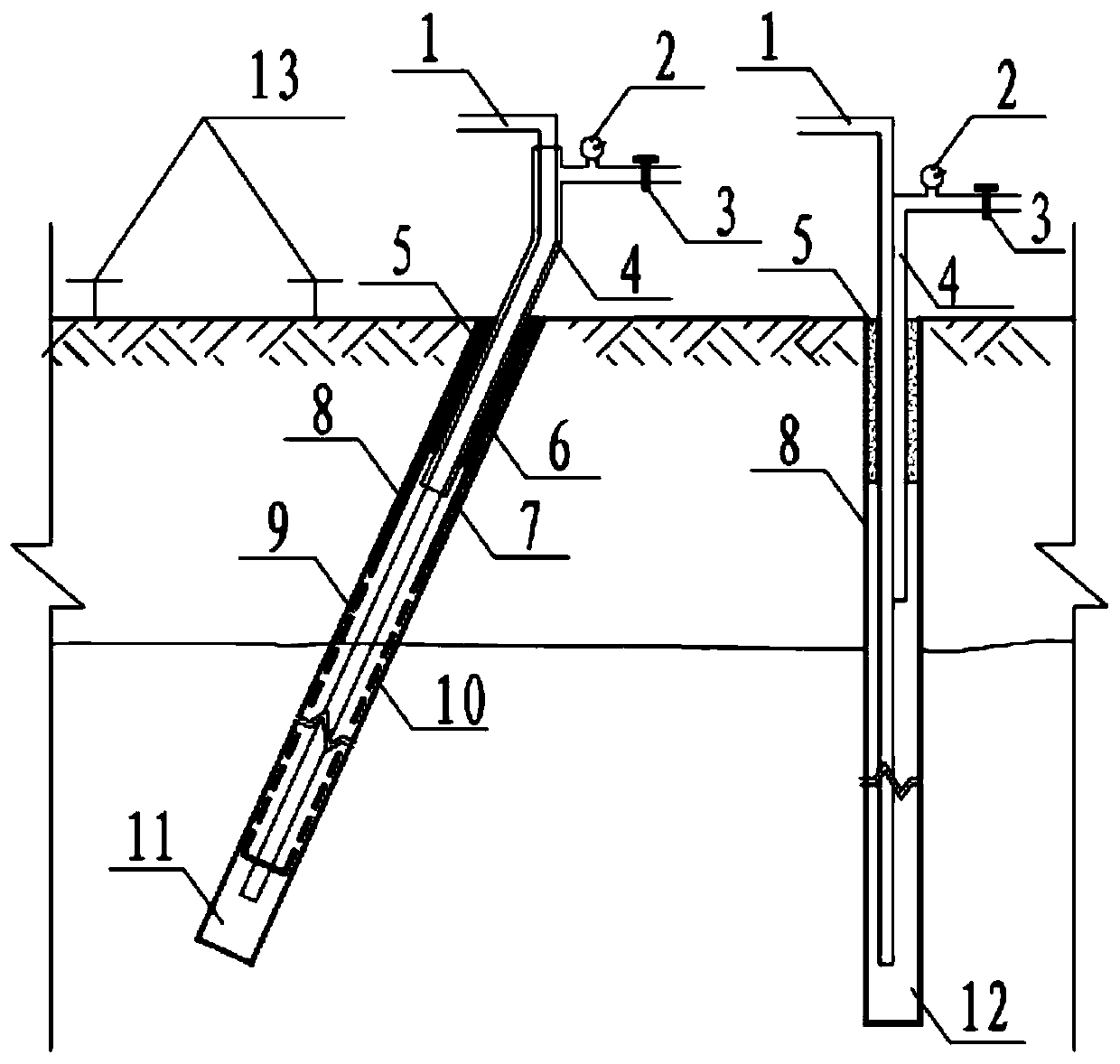

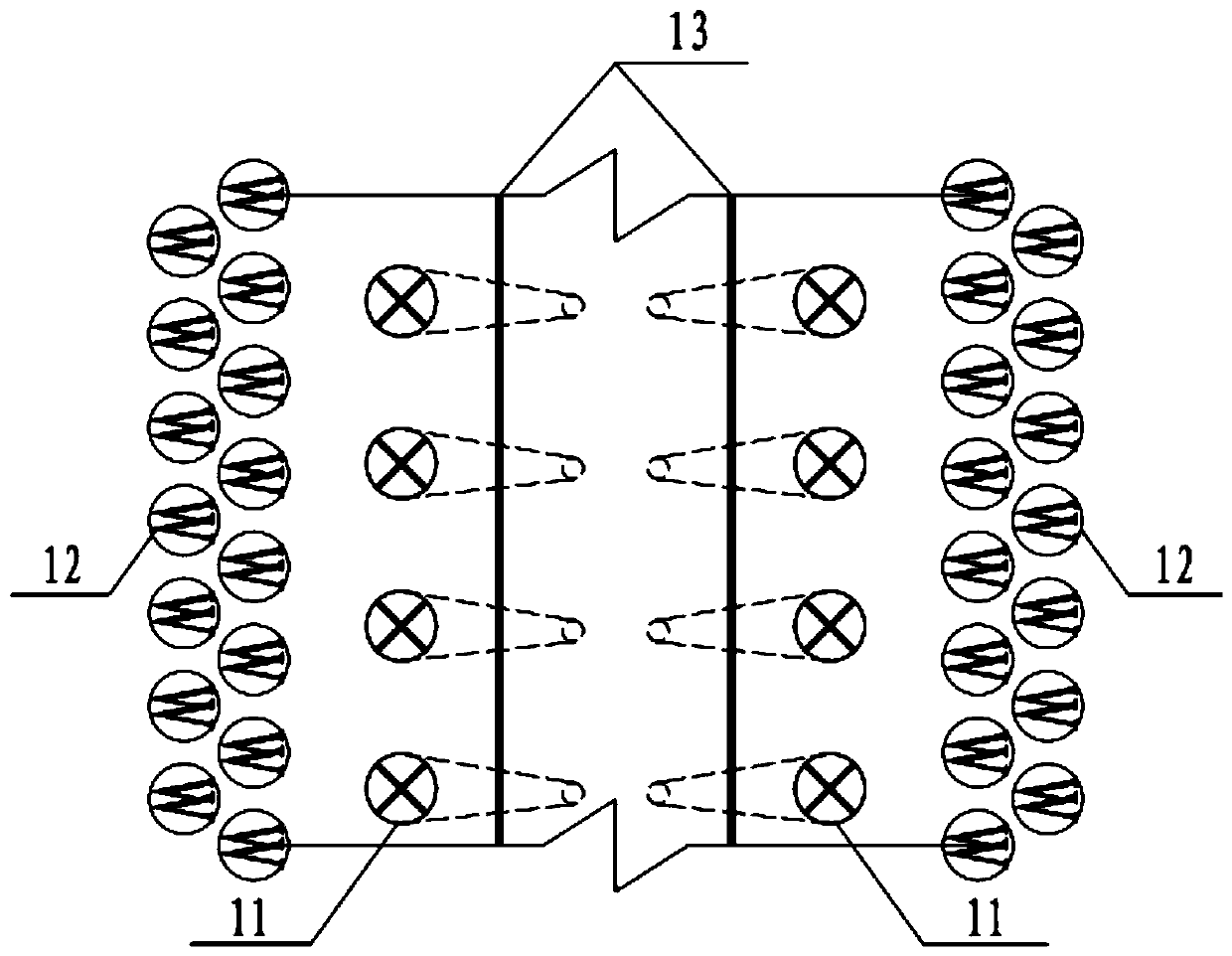

[0029] Such as figure 1 and figure 2 As shown, the comprehensive treatment method for subgrade karst collapse in this embodiment includes the following steps:

[0030] Step 1. Conduct geological exploration within the range of line 13 by seismic surface wave and radar method, and determine the development of karst in combination with core drilling and water pressure test;

[0031] Step 2: Drill inclined holes 11 and straight holes 12 in the karst-developed section. The inclined holes 11 are one row on each side of the line 13 and are drilled obliquely towards the center of the line 13. The straight holes 12 are two rows on each side of the line 13. And it is located outside the oblique hole 11.

[0032] Step 3: After the drilling is completed, set the grouting pipe 1 and the grouting pipe 4 for the inclined hole 11 and the straight hole 12, and set the pressure gauge 2 and the valve 3, and seal the inclined hole 11 and the straight hole 12;

[0033] Step 4: Perform pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com