Demolition construction method for bridge superstructure

A construction method and bridge technology, applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve the problems of imprecise hoisting arrangement and safety considerations, difficult implementation of mechanical equipment, insufficient bridge protection, etc., so as to be easy to grasp and implement, Demolition safety, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

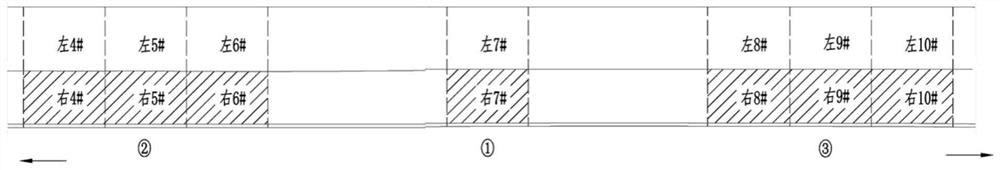

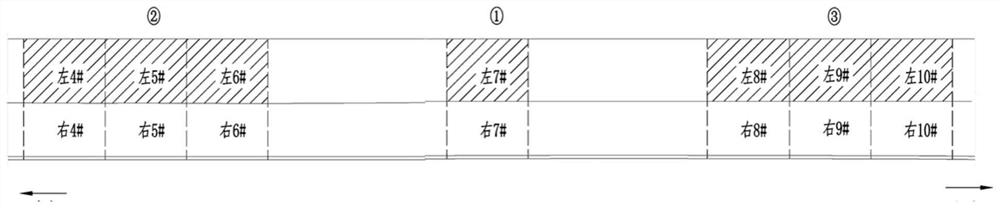

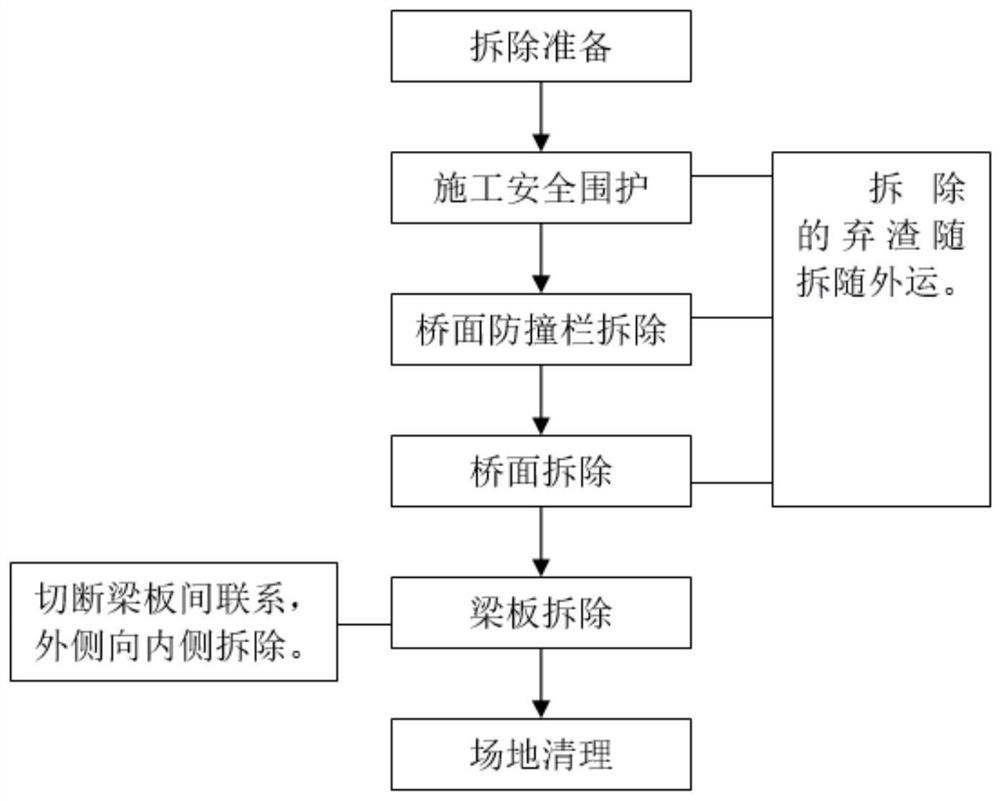

[0035] In order to facilitate understanding and description of the technical solution of the present invention, a certain section of bridge is selected as an example to describe in practice. The bridge has a total length of 417m. Ordinary concrete cast-in-place T beams, 25m prefabricated prestressed T beams, 15 holes in total; the demolition work is carried out in two stages: the first stage is to demolish the right (single) bridge deck and 28 pieces of T beams (including the main span of 25m fully hung Beams, semi-hanging beams and ordinary 25m prestressed T-beams); in the second stage, the left (single) bridge deck and 28 T-beams will be demolished. The demolition diagram is as follows figure 1 and figure 2 shown.

[0036] Only 4 T-beams need to be removed # 、5 # 、6 # 、7 # ,8 # ,9 # 、10 # A total of seven spans ( figure 1 and figure 2 The shaded part shown in ), combined with the actual situation on site, divided into three areas for demolition.

[0037] ①The No...

Embodiment 2

[0061] This embodiment provides the method for dismantling and hoisting safety calculation in Embodiment 1.

[0062] (1) Calculation of the weight of the removed beam

[0063] The concrete quantity of a main girder is shown in Table 1, and the self-weight Q of the most unfavorable middle girder (difficult) is taken 1 = 50.02t.

[0064] Table 1: Concrete Quantity Table for a Main Girder

[0065]

[0066] The average thickness of bridge deck pavement is 13cm, and the self-weight Q is calculated 2 =0.13×25×2.3×2.5=18.7t.

[0067] The number of prestressed steel tendons in a T-beam is shown in Table 2, and the total weight of prestressed steel tendons Q 3 = 0.57t.

[0068] Table 2: Quantity of Prestressed Tendon Materials for a T-beam

[0069]

[0070] Therefore, the hoisting weight of a center beam Q=Q1+Q2+Q3=50.02+19.07+0.57=69.66t, rounded to 70t.

[0071] (2) Selection of hoisting machinery and spreaders

[0072] According to the above calculation results, projec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com