Method for embedment of grouting hole in base plate of underground chamber

A technology for underground caverns and grouting holes, which is applied in soil protection, protection devices, construction, etc., can solve the problems of troublesome digging and difficulty in controlling the influence range of the waterproof layer, so as to reduce the operation period and eliminate the need for chiseling and removing concrete. The effect of the construction process and the reduction of operational impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] The present invention is a method for reserving grouting holes, the steps of which are as follows.

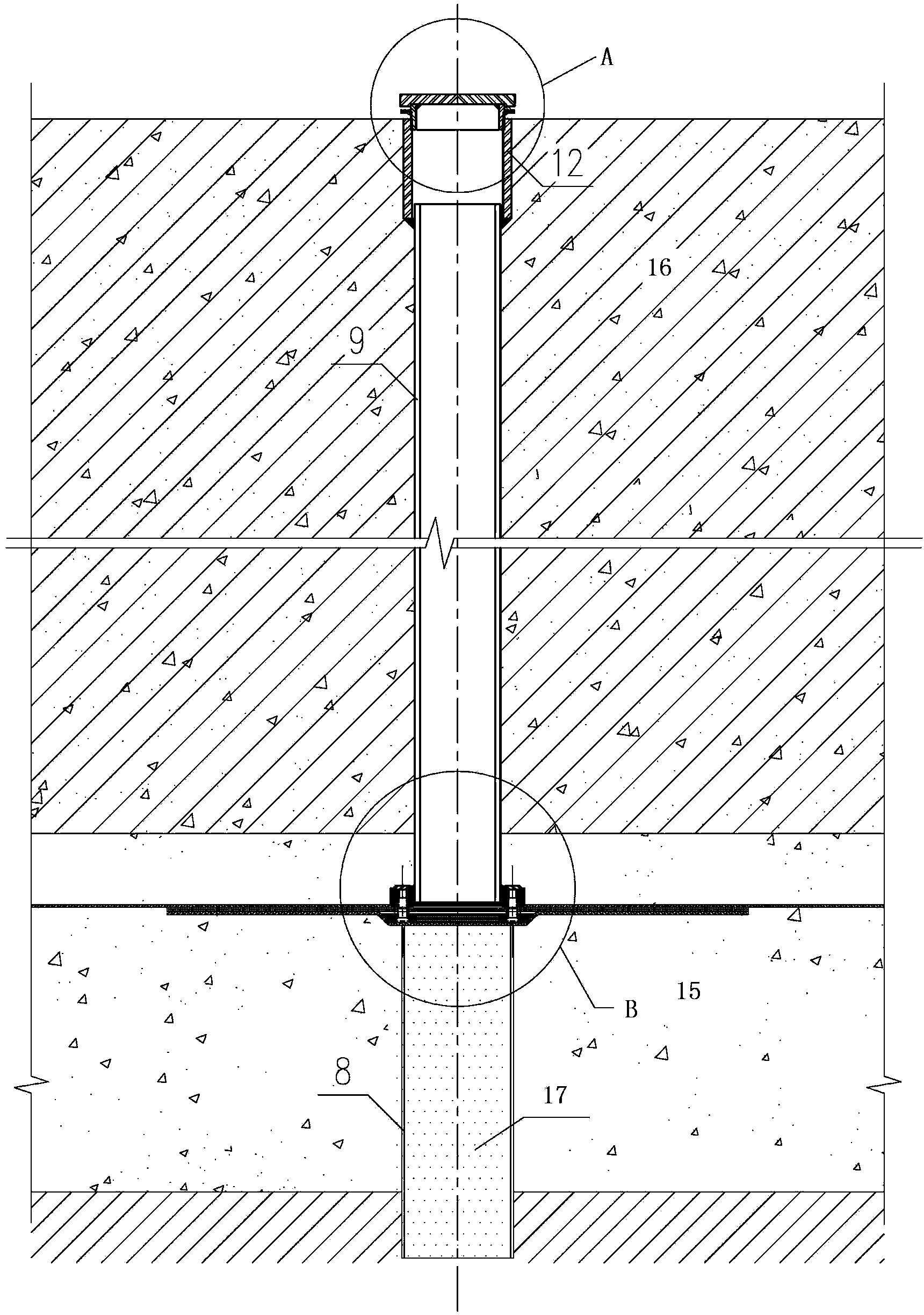

[0013] 1. Set the cushion grouting hole buried pipe 8 in the plain concrete cushion according to the specified position (the pipe can be made of PVC and other engineering plastic materials, and the pipe can be filled with cohesive soil 17 or other materials).

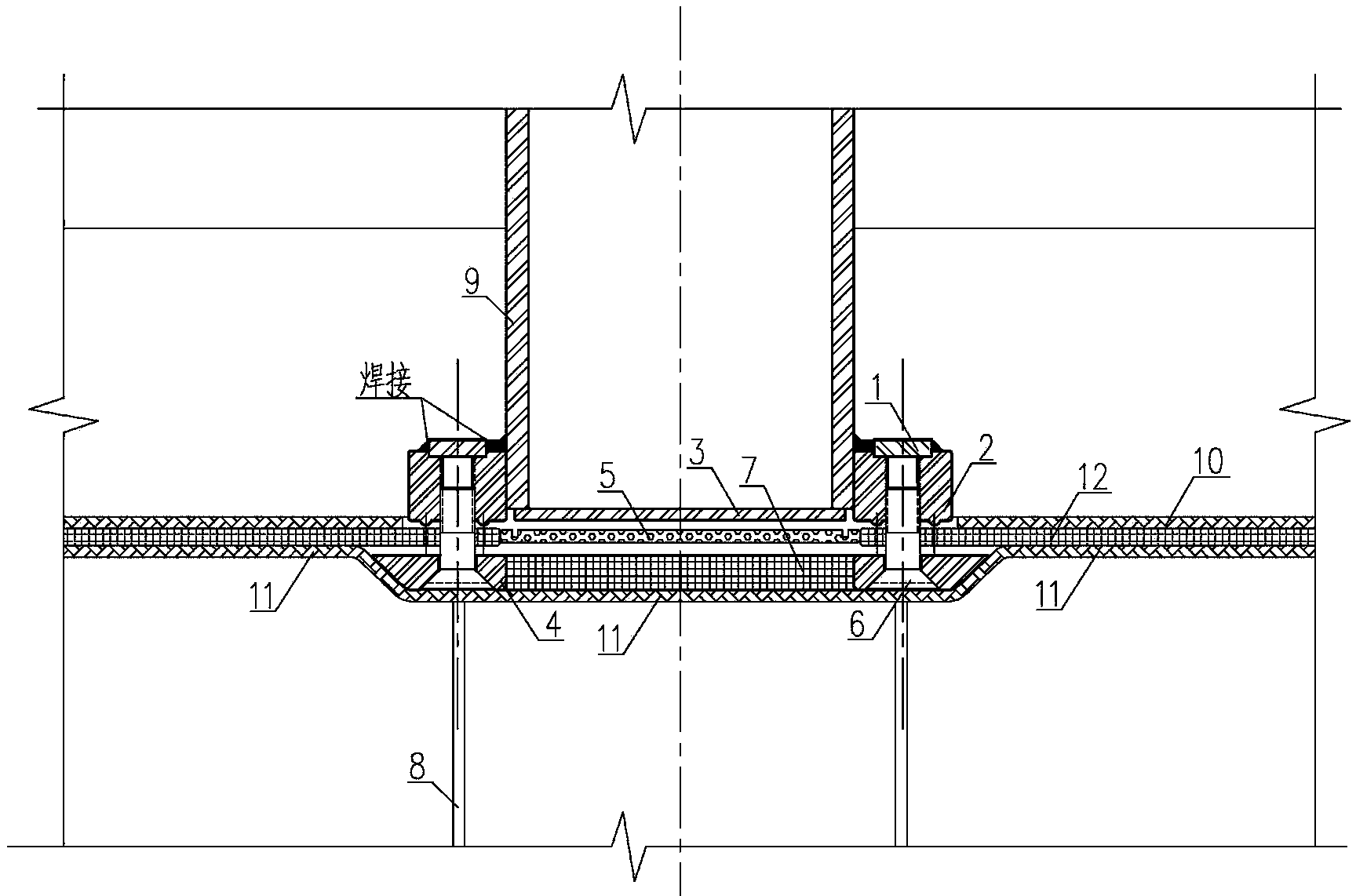

[0014] 2. Install the grouting hole buried pipe assembly on the upper part of the grouting hole buried pipe in the cushion layer. The buried pipe assembly is a supporting product of the factory-made components. The capping cover and the grouting hole bottom sealing device, the bottom plate grouting hole buried pipe is connected with the cushion layer grouting hole buried pipe through the grouting hole bottom sealing device, and the factory manufacturing and on-site assembly method steps are as follows.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com