Method for jacking main coolant pump motor rotor of nuclear power station

A technology of main coolant and motor rotor, applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of high collective radiation dose of the working group, affecting the assembly quality of the main pump motor, increasing the risk of equipment damage, etc., to reduce the number of cooperative operations The effect of reducing the number of people, reducing the risk of equipment damage, and shortening the operation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

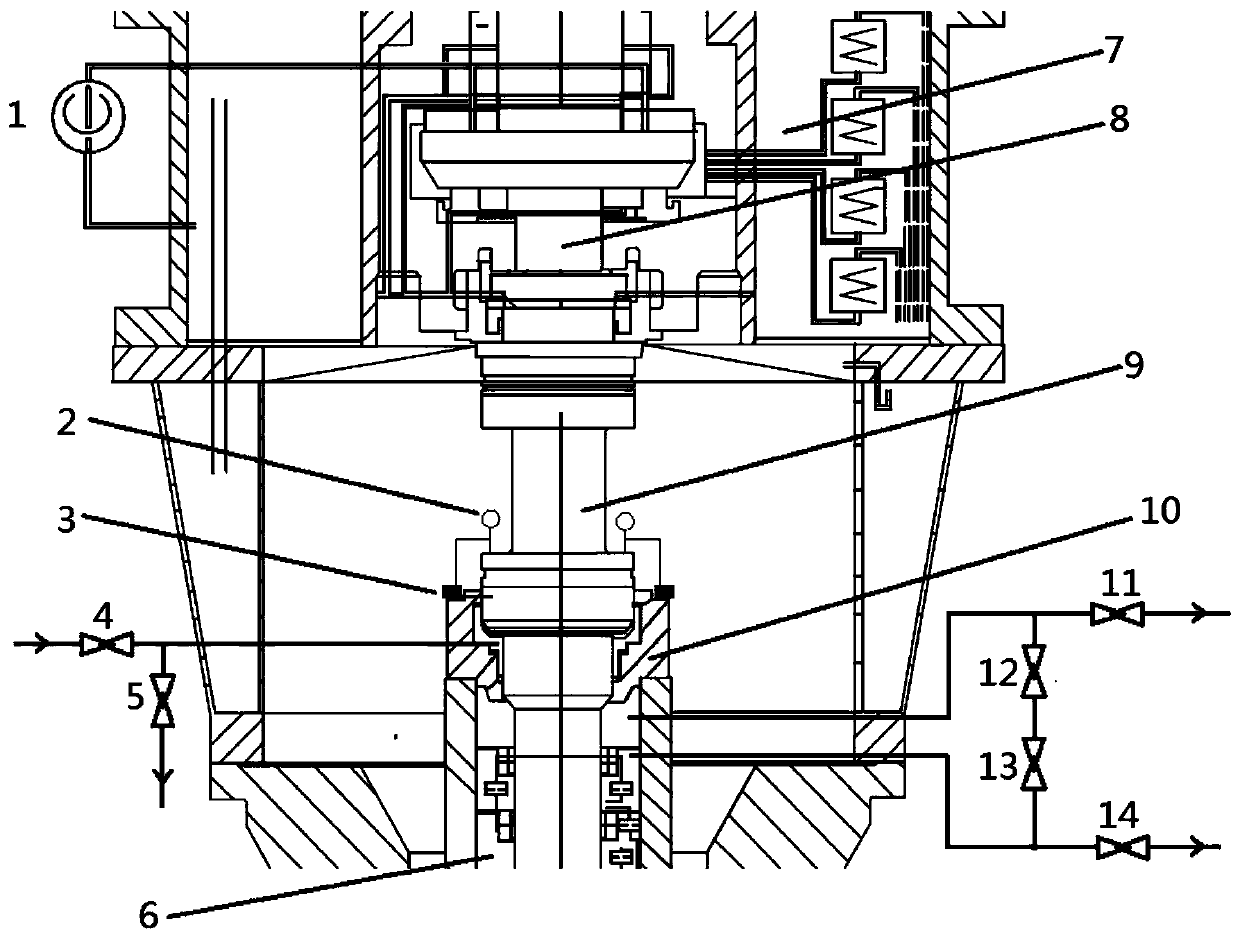

[0037] A method for jacking up the rotor of a main coolant pump motor in a nuclear power plant, using the following jacking device for operation, such as figure 1 As shown, the jacking device includes a dial indicator 2, a magnetic gauge seat 3, a nitrogen isolation valve 4, an exhaust valve 5, a low pressure leakage isolation valve 11, a high and low pressure leakage communication valve A12, a high and low pressure leakage communication valve B13, High pressure leak isolation valve 14.

[0038] The main coolant pump includes a jacking shaft oil pump 1 , a mechanical seal 6 , a motor 7 , a motor rotor 8 , an intermediate short shaft 9 , and a parking seal 10 . Wherein, the bottom end of the motor rotor 8 is connected with the top end of the intermediate short shaft 9 . The upper part of the parking seal 10 is connected with the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com