A large formwork support method for constructing concrete retaining walls without anchors

A support method and technology of large formwork, applied in construction, underwater structures, infrastructure engineering, etc., can solve problems such as appearance quality and flatness effect that is difficult to achieve with fair-faced concrete, less frequent use of formwork turnover, and increased construction costs. , to achieve the effect of reducing appearance treatment, shortening operation period and simple reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings.

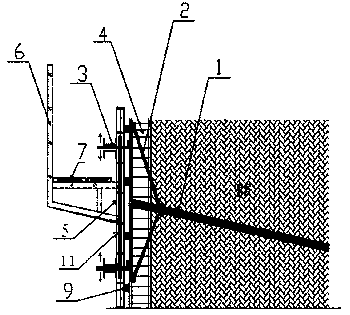

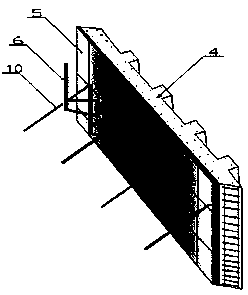

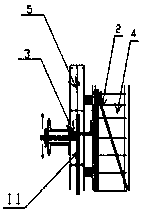

[0019] A concrete retaining wall without anchors, comprising concrete retaining wall reinforcement 4, the concrete retaining wall reinforcement 4 is used to construct a concrete retaining wall covering a slope, and also includes a slope protection anchor rod 1 and tie bars 2;

[0020] One end of the slope protection anchor rod 1 is inserted obliquely downward into the rock formation of the slope body, and the other end of the slope protection anchor rod 1 is exposed outside the slope body and runs through the concrete retaining wall reinforcement 4 obliquely upwards and is connected with a cantilever length The middle position of the direction is fixedly connected, and the cantilever abuts against the outer side of the concrete retaining wall reinforcement 4 away from the slope;

[0021] Between the two ends of the cantilever and the rock-entry end located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com