Method for changing and transferring catenary rods

A catenary and frame bridge technology, applied in the direction of overhead lines, building types, buildings, etc., can solve the problems of large changes in catenary poles, high construction costs, high risks, etc., and achieve small impact, simple construction, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

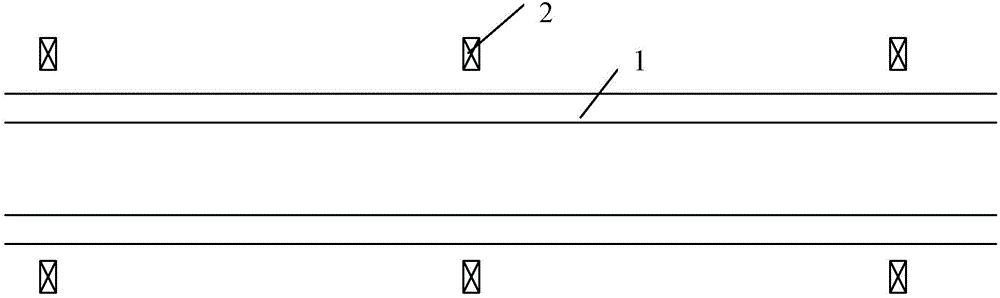

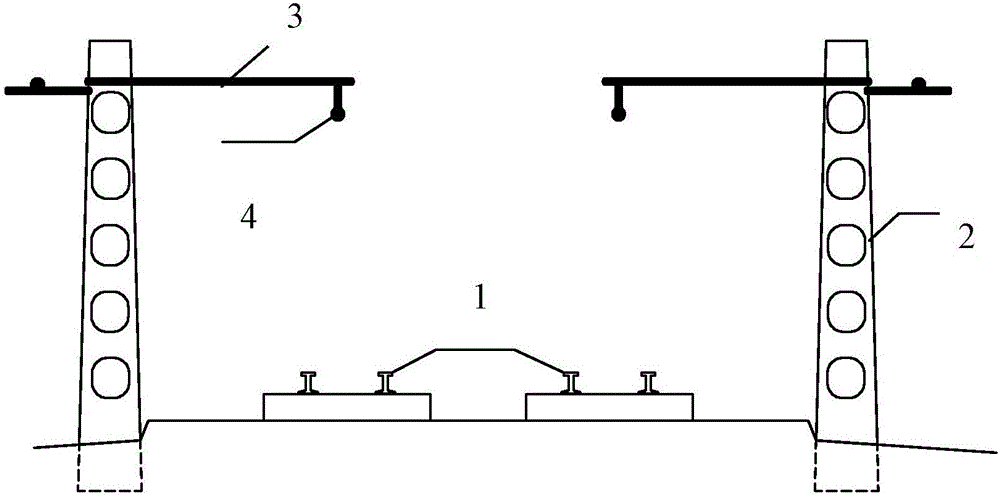

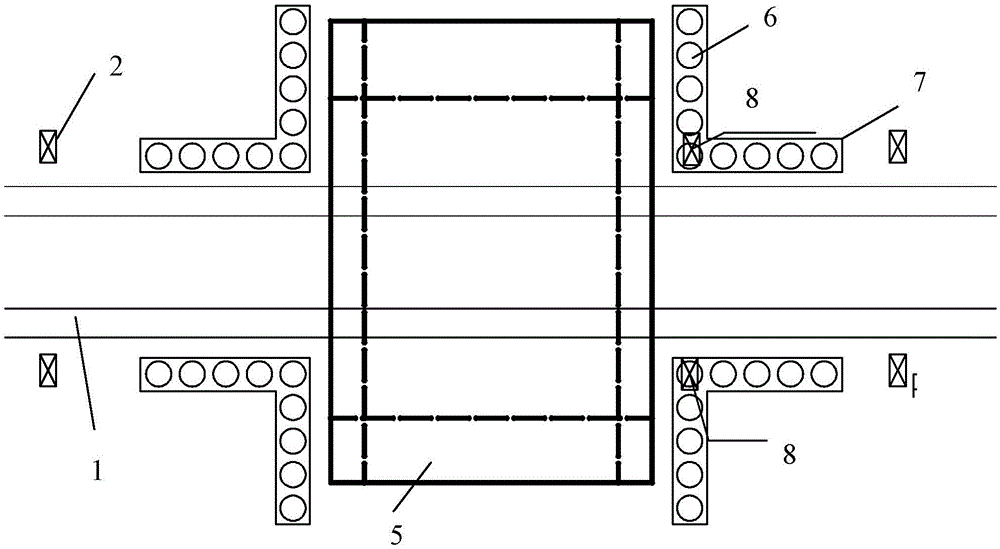

[0023] The catenary pole modification method provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The same reference numerals are used for the same components as in the prior art.

[0024] like image 3 — Image 6 As shown, the method for changing catenary rods provided by the invention includes the following steps carried out in order:

[0025] 1) Before the frame bridge 5 is jacked, a set of L-shaped reinforced concrete protection piles 6 and a reinforced concrete crown beam 7 at the top of the group of protection piles 6 are respectively installed on the railway subgrade on both sides of the front and rear ends of the frame bridge 5 to be installed. For railway subgrade protection, in the process of setting up protective piles 6 and crown beams 7, multiple screws and bolts are pre-embedded on the top of the crown beam 7 at the corner on one side, and the steel truss is softly spanned ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com