Railway construction method of dismantling existing girder bridge and pushing frame structure in situ

A technology with existing railways and construction methods, applied to bridges, bridge maintenance, bridge reinforcement, etc., can solve the problems that D beams cannot be used to reinforce lines in double-track sections, railway reconstruction sections cannot be used, and busy railways have been interrupted for a long time. Achieve the effects of small impact on railway operation, unapplicable solutions, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

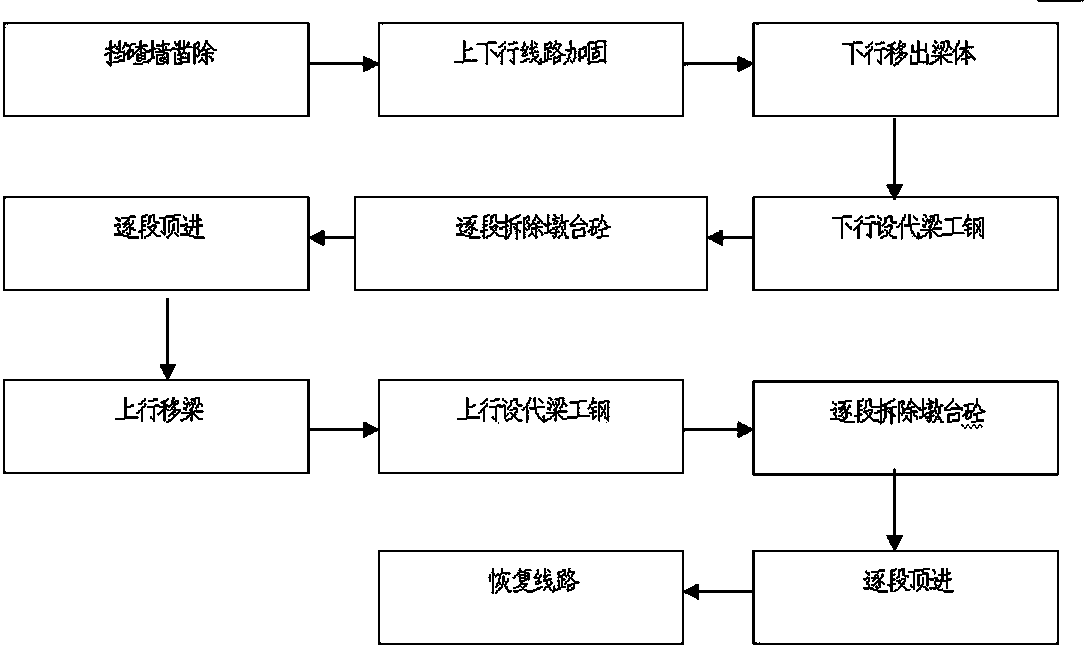

[0032] The construction method of a kind of existing railway demolition beam bridge in situ jacking frame structure bridge of the present invention, such as figure 1 , the construction steps are as follows:

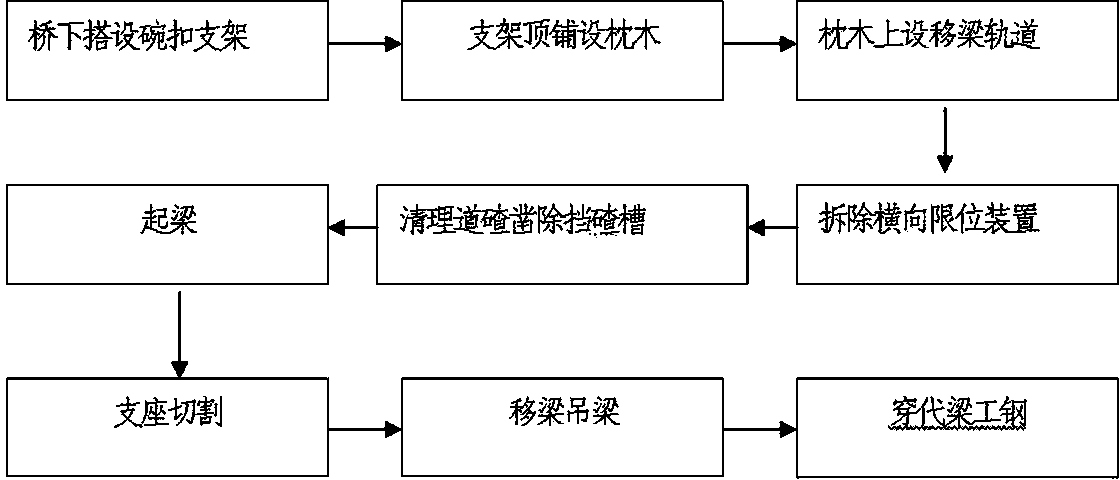

[0033] (1) Set up the beam moving bracket and slideway

[0034] Bowl-buckle beam-moving support 1 is set up under the bridge. The foundation of moving beam support 1 is the existing concrete pavement. Lay a layer of sleepers, lay two steel rail slideways on the sleepers, put a small block between the rail slideway and the beam, and the small block is a small block commonly used for moving the turnout.

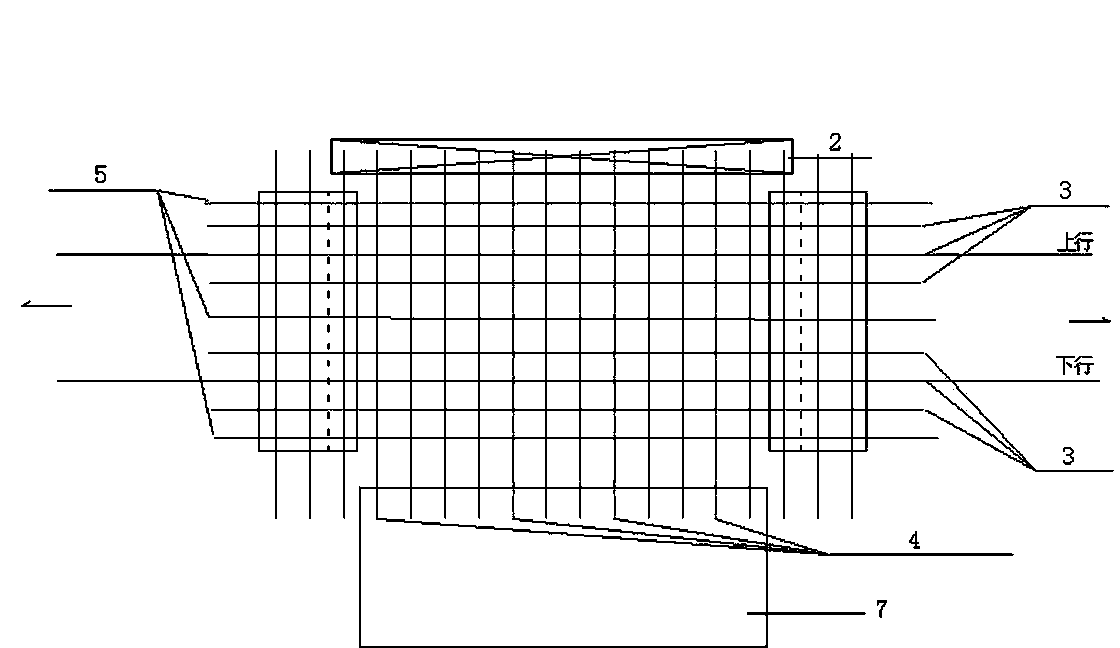

[0035] Such as Figure 4 As shown, sleeper piles 2 are set up on both sides of the lower beam of the bridge, and the width of sleeper piles 2 is 4.5m outside the I-beam beam 4, which is used for the beam platform and supports the I-beam beam 4, which is enough to place two beams.

[0036] (2) The line is reinforced by buckle rail and longitudinal and beam method

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com