A construction method for jacking the box under the hump line

A construction method and jacking technology, which is applied to artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of not being allowed to be closed for a long time and cannot be completed, and achieve the effect of low construction cost, good effect and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

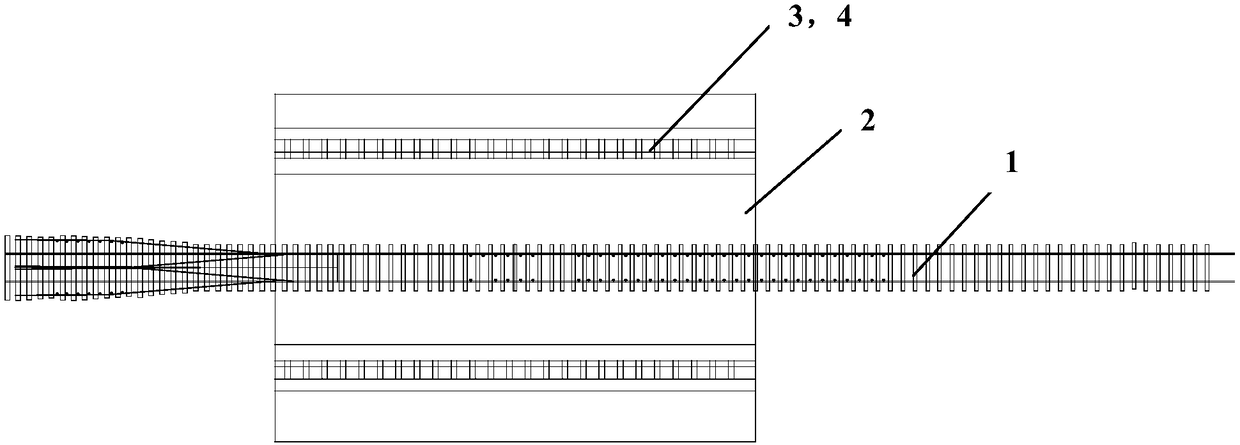

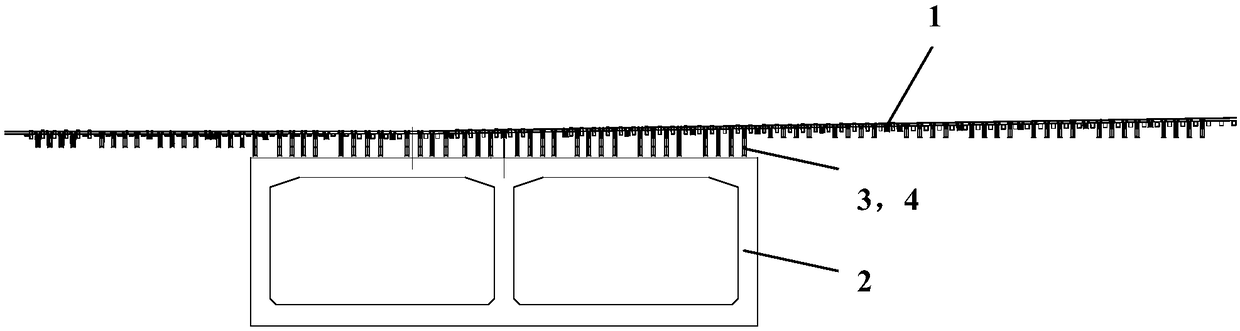

[0027] Such as figure 1 As shown, the construction method for jacking the cabinet under the hump line provided in this embodiment includes the following steps in order:

[0028] 1) First, adopt the traditional line reinforcement system consisting of 3-5-3 suspension rails and I-beam longitudinal beams to reinforce the existing railway line 1 in the area affected by jacking on the hump line, and remove the rubble in this area retaining wall;

[0029] 2) Prefabricate a multi-section reinforced concrete box 2 in the foundation pit located on the side of the above-mentioned existing railway line 1. During the prefabrication process, the position corresponding to the retaining wall on the top plate of the box 2 is reserved for connecting the prefabricated block of the retaining wall steel bars;

[0030] 3) At the same time, the prefabricated block of the reinforced concrete structure of the retaining wall is prefabricated outside the site. The width of the prefabricated block of ...

Embodiment 2

[0035] Such as figure 1 As shown, the construction method for jacking the cabinet under the hump line provided in this embodiment includes the following steps in order:

[0036] 1) First, adopt the traditional line reinforcement system consisting of 3-5-3 suspension rails and I-beam longitudinal beams to reinforce the existing railway line 1 in the area affected by jacking on the hump line, and remove the rubble in this area retaining wall;

[0037] 2) Prefabricate a multi-section reinforced concrete structure box 2 in the foundation pit on one side of the existing railway line 1 above, and reserve steel bars at the position corresponding to the retaining wall on the top plate of the box body 2 during the prefabrication process;

[0038] 3) After the concrete in the box body 2 reaches the predetermined strength requirement, a reinforcement cage for the prefabricated hump retaining wall 4 is made at the above-mentioned reserved reinforcement, and a formwork for the prefabricat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com