Prestress anchor clamping method for dismantling brick masonry wall piece

A prestressed, brick masonry technology, used in building maintenance, construction, building construction, etc., can solve the problems of easy tilting of wall pieces, unsafe and stable transportation and hoisting, damage, etc., to simplify the construction process, enhance Overall performance, the effect of avoiding flip damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

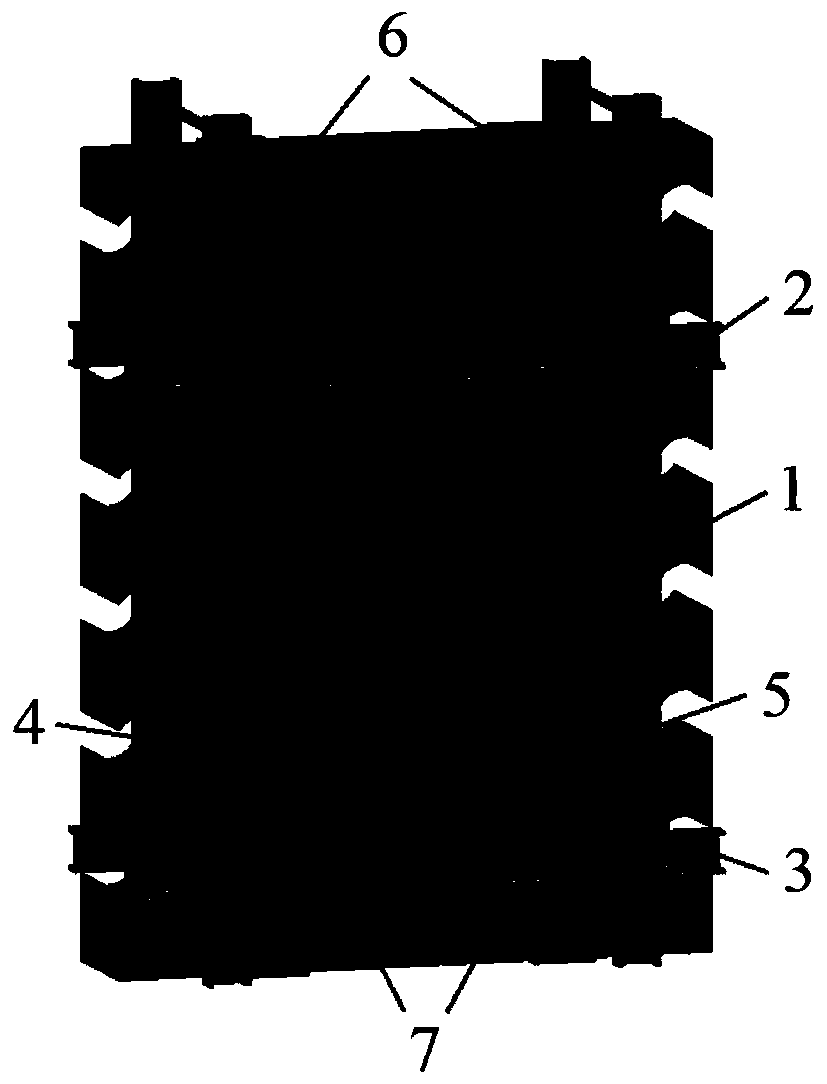

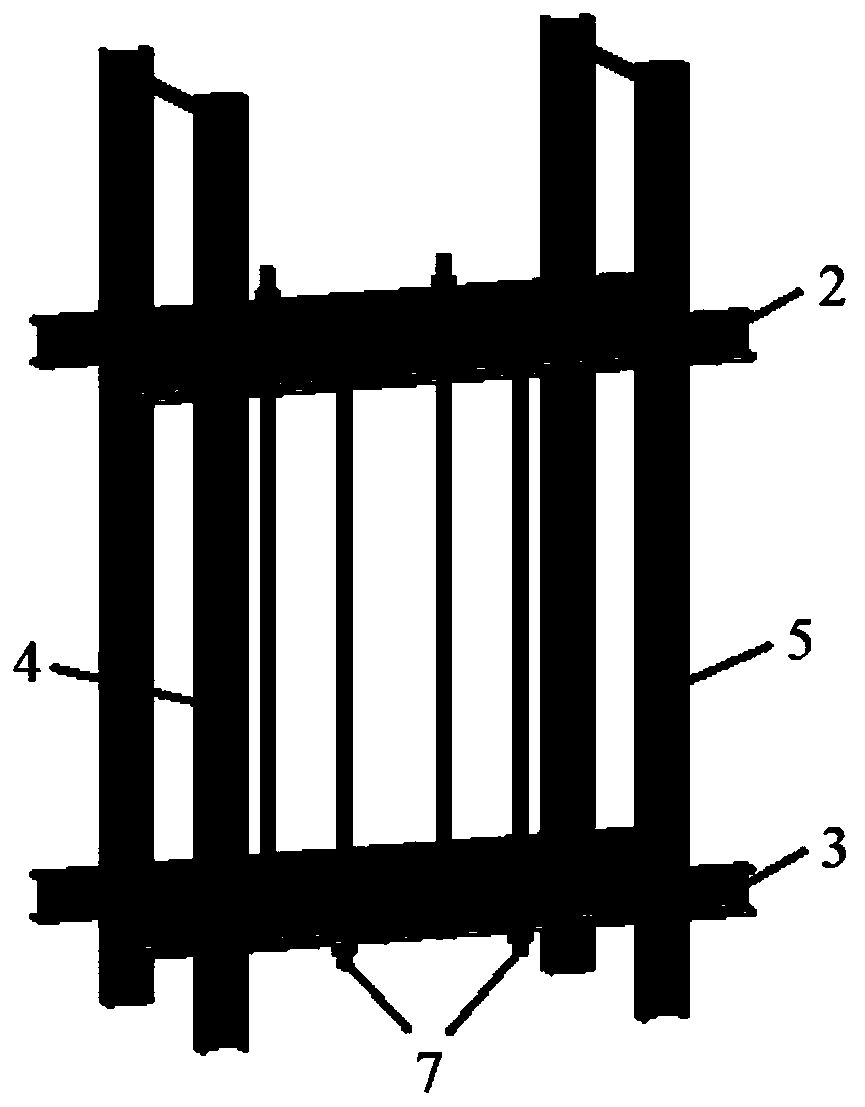

[0014] Specific implementation mode one: combine figure 1 and figure 2 Illustrate this embodiment, a kind of prestressed anchor clip method for removing brick masonry wall piece in this embodiment is specifically carried out according to the following steps:

[0015] 1. Place the wooden square 6 on the front and rear sides of the demolished brick masonry wall piece 1 and fix it;

[0016] 2. Assemble the two sets of prestressed anchor clip frames on both sides of the demolished brick masonry wall piece 1;

[0017] 3. Install a prestressed lead screw 7 between the upper frame 2 and the lower frame 3 of the prestressed anchor clip frame, and adjust the screw nut to provide prestress for the prestressed anchor clip frame;

[0018] Four, pass steel wire rope through the cross bar that the left frame 4 of prestressed anchor clip frame and the top of right frame 5 are provided with, can carry out hoisting and transportation that demolition brick masonry wall piece 1 is carried out...

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the demolition of the brick masonry wall piece 1 in step 1 is dismantled by industrial demolition. Others are the same as the first embodiment.

specific Embodiment approach 3

[0020] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the frame of the prestressed anchor clip described in step two is composed of an upper frame 2, a lower frame 3, a left frame 4 and a right frame 5; The frame 2 and the lower frame 3 are arranged in parallel, bolt holes are provided at both ends of the upper frame 2 and the lower frame 3, and the upper frame 2 and the lower frame 3 are respectively connected to the demolished brick masonry wall piece 1 by bolts; The left frame 4 is vertically arranged at the left end of the upper frame 2 and the lower frame 3, and the right frame 5 is vertically arranged at the right end of the upper frame 2 and the lower frame 3; the flanges of the upper frame 2 and the lower frame 3 A pair of through holes are provided for connecting the prestressed screw 7. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com