Lifting transportation process of wind power steel pipe piles

A steel pipe pile and hoisting technology, which is used in transportation and packaging, load handling devices, cargo handling equipment, etc., can solve problems such as increasing the difficulty of deck transportation and lashing, affecting the normal running of transport ships, and damage to the surface of steel pipe piles. , to achieve the effect of stable and orderly process steps, avoiding shaking and stable hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

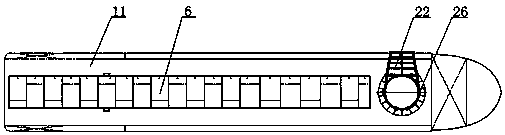

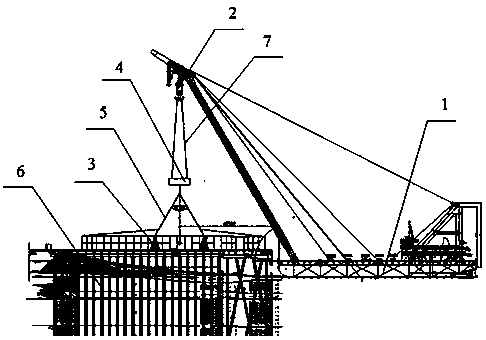

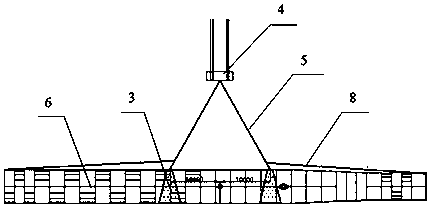

[0038] Such as figure 1 As shown, a wind power steel pipe pile hoisting and transportation process, the wind power steel pipe pile includes a pile body, a flange part and a connecting part connecting the cylinder part and the flange part, and the inner diameter of the flange part is smaller than that of the cylinder part The diameter of the inner circle, the weight of the steel pipe pile 6 is G, the diameter of the pile body is D, the pile length is L, the distance between the center of gravity and the flange is L, including selecting the floating crane and calculating the hoisting parameters of the floating crane, Select the lifting point of the steel pipe pile, select the transport ship, select the transport supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com