Lifting appliance

A spreader and hanger technology, which is applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of bumps on the sealing surface, difficulty in connecting parallel surfaces, and affecting the assembly quality, so as to achieve stable hoisting and reduce processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

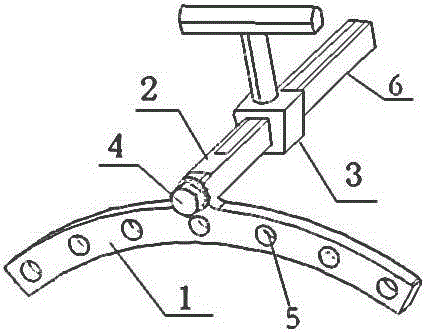

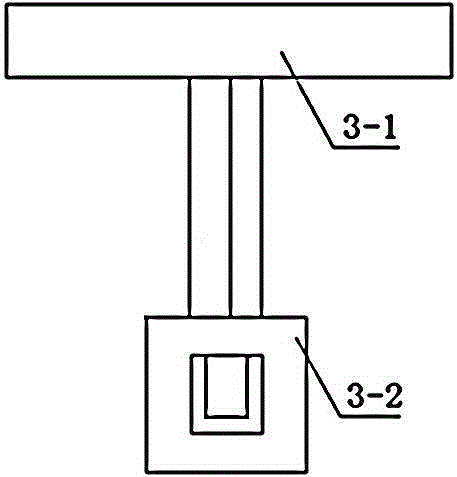

[0015] a spreader, such as Figure 1-2 As shown, it includes a hanger, and the hanger includes an arc-shaped connecting plate 1 for bonding with the end face of the pot insulator and a guide rail 2 connected to the connecting plate 1 through a connecting bolt 4 at one end. The guiding direction of the guide rail 2 In the same direction as the axis of the pot insulator, a lifting device connector 3 is installed on the guide rail 2 for guiding movement. The arc-shaped connecting plate 1 is provided with 7 connection holes 5 at intervals along its circumferential direction, which are used to fix and connect the pot insulator. The pot insulator is embedded with a double-screw screw, and the axis direction of the double-screw screw is the same as the pot The axial direction of the insulator is the same and runs through the two end faces of the pot insulator. The connecting hole 5 and one end of the double-screw head screw are fixedly connected by a nut to fix the pot insulator on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com