Long-span steel beam lifting appliance and steel beam lifting method thereof

A hoisting method and large-span technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficulty in meeting construction requirements, bulky structure of spreaders, and very high requirements for lifting equipment, and achieve light structure and force transmission. Immediate, weight-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

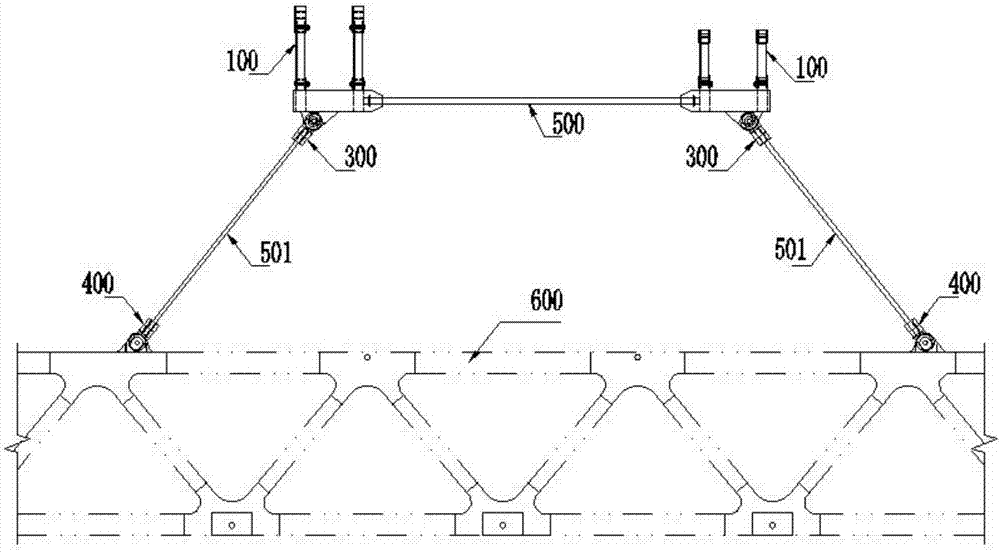

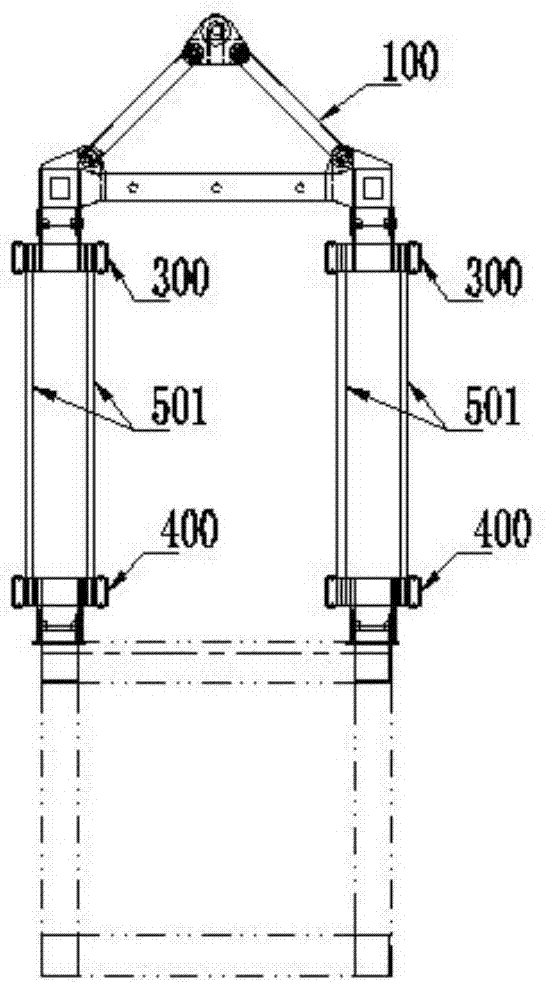

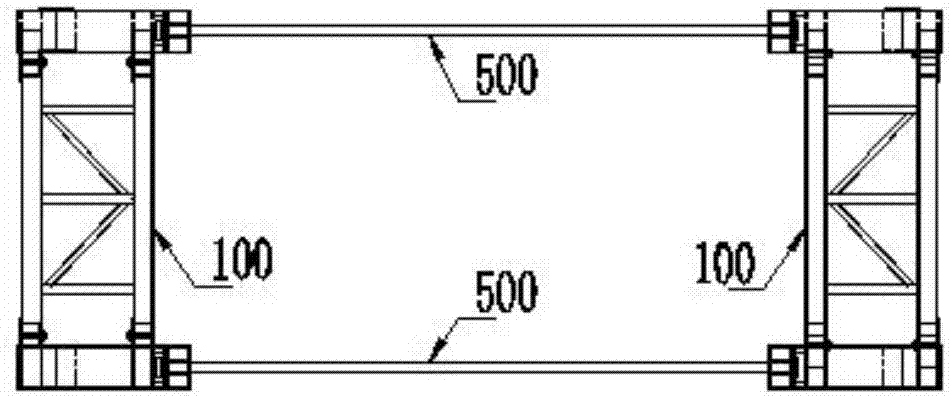

[0038] see Figure 1-Figure 3 As shown, the embodiment of the present invention provides a large-span steel beam hoisting sling, which is used for lifting a large-span steel beam 600, which includes:

[0039] Two booms arranged at intervals, each boom includes a shoulder pole beam 100 and two first stay cables 501, and the top ends of the two first stay cables 501 are respectively connected to two bottom ends of the corresponding shoulder pole beam 100. side; since the steel beam 600 has a rectangular parallelepiped structure, in order to ensure the stability of the steel beam 600 during hoisting, it is necessary to connect one of the first cables 501 on both sides of the steel beam 600, and the two The connecting line between the first cable 501 and the connection point of the steel beam 600 is preferably perpendicular to the length directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com