Hoisting method and hoisting device for concrete prefabricated box beam

A hoisting device and hoisting method technology, applied in bridges, bridge construction, transportation and packaging, etc., can solve the problems of box girder hoisting holes and abdomen damage, difficulty in installing box girder in place, hidden dangers of rope hoisting, etc. Less damage, balanced hoisting, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

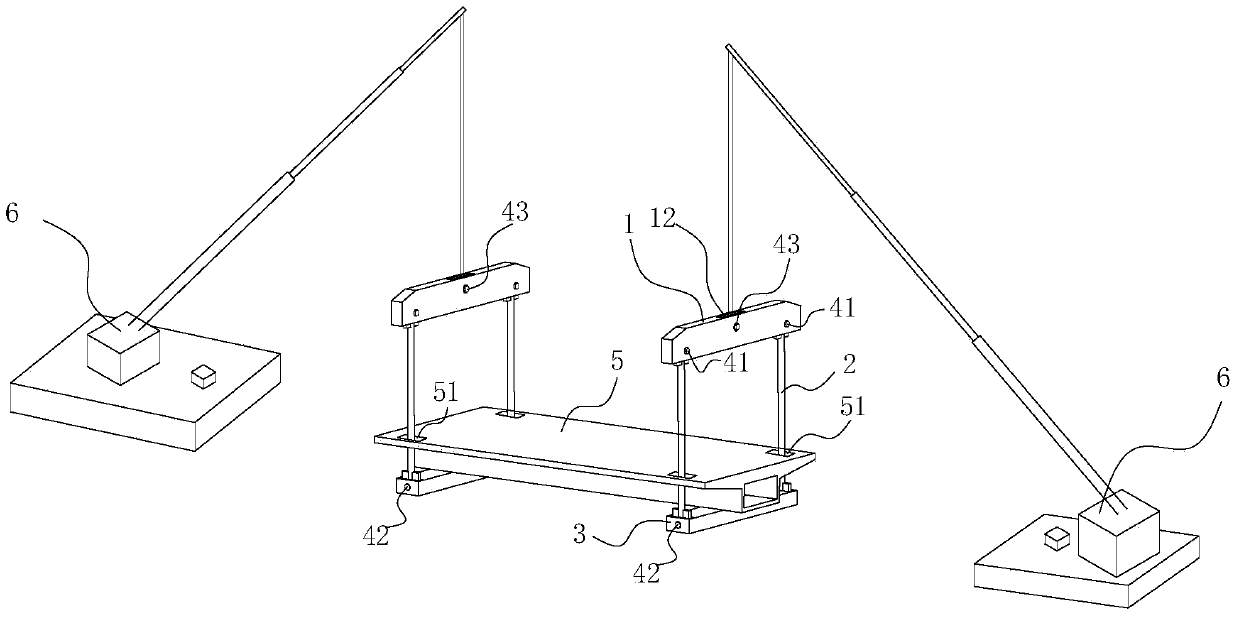

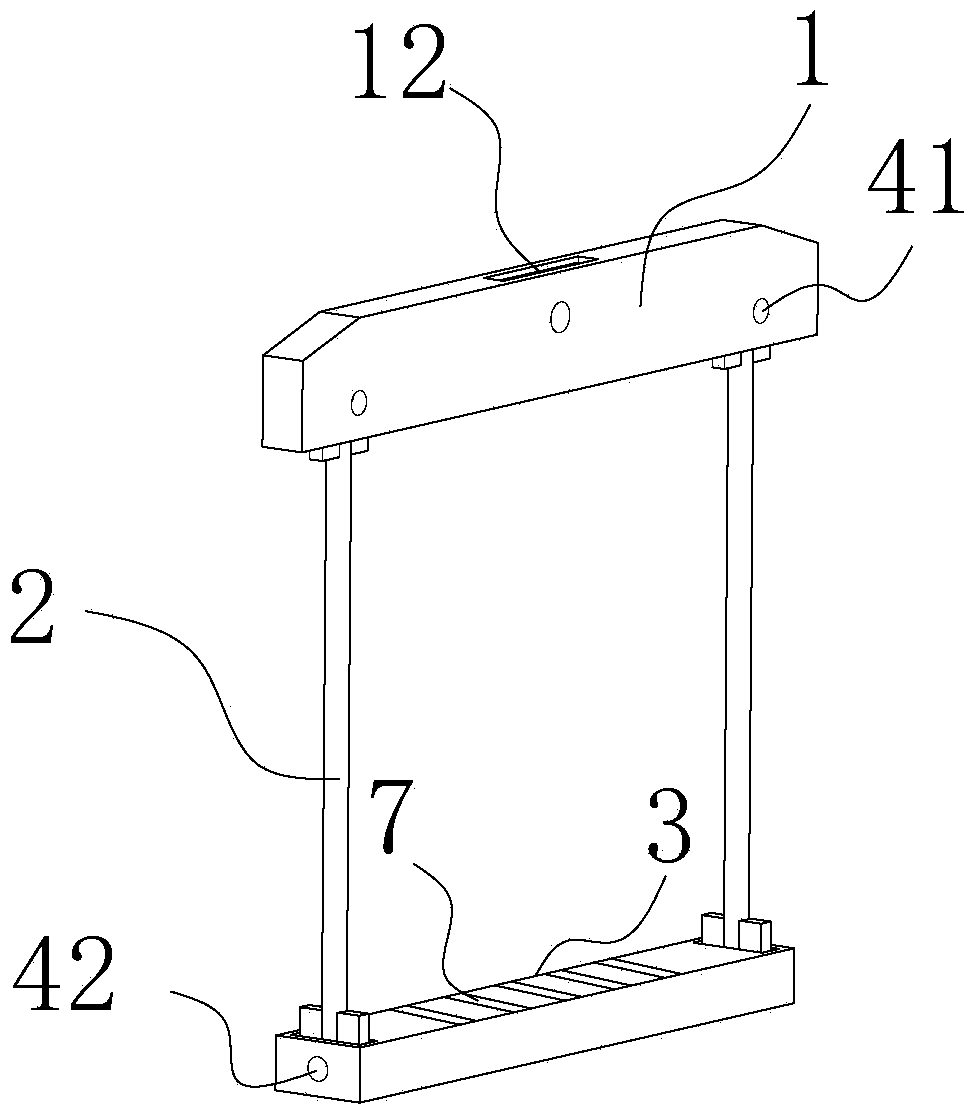

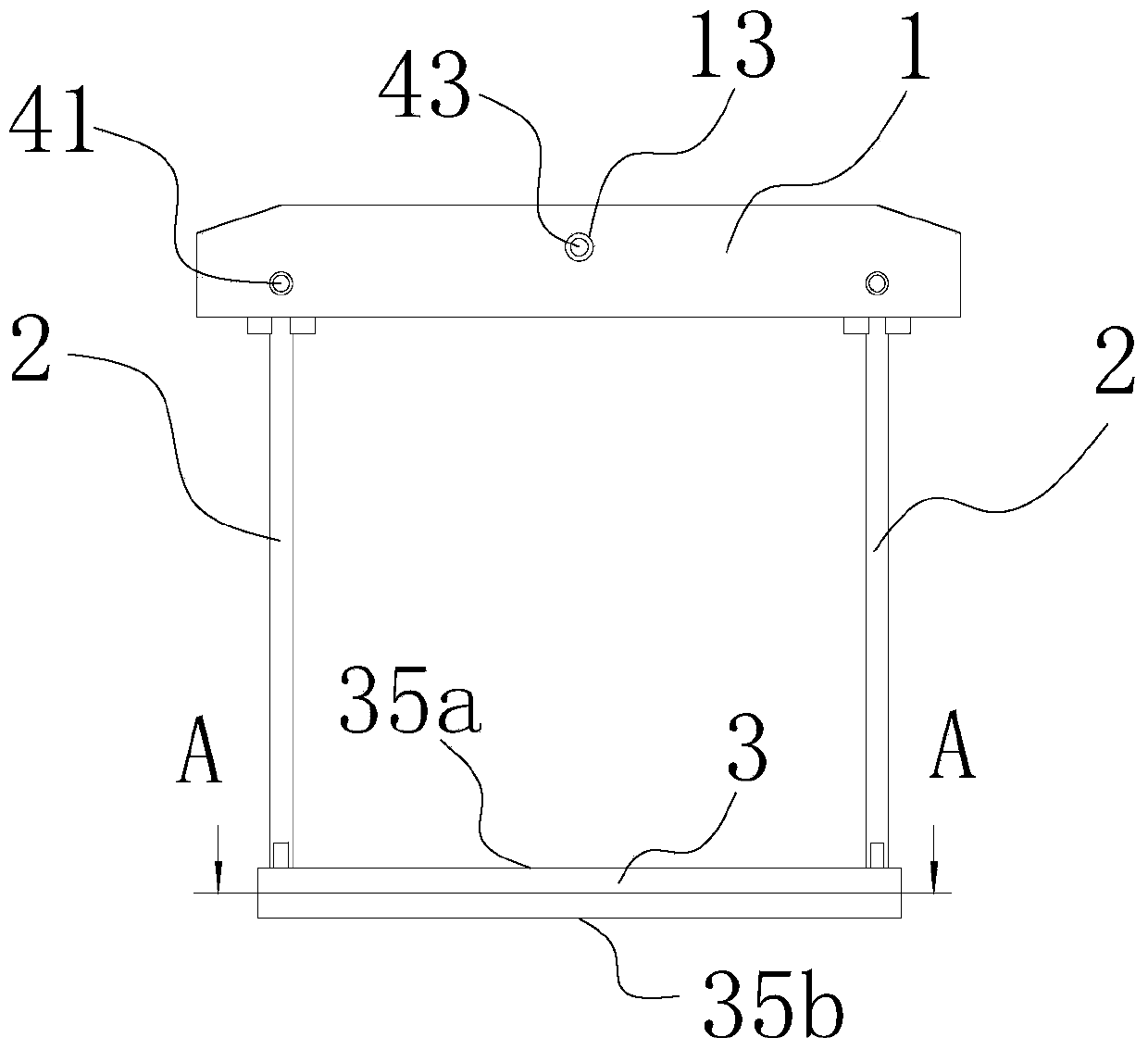

[0053] Such as Figure 2 to Figure 8 As shown, the concrete prefabricated box girder hoisting device includes a balance beam 1, a connecting rod 2, and a beam 3. Both ends of the balance beam 1 are connected to the connecting rod 2 through a first connection structure, and the two ends of the beam 3 are connected through a second connection. The structure is connected with the connecting rod 2 which is located between the balance beam 1 and the cross beam 3 . The balance beam 1 is provided with a hoisting structure. The first connection structure includes an upper pin shaft 41, pin holes 22 are provided at both ends of the connecting rod 2, and upper pin holes are provided on the balance beam 1; the second connection structure includes a lower pin shaft 42 , the beam 3 is provided with a lower pin hole 34; the upper pin 41 passes through the pin hole 22 at one end of the connecting rod 2 and matches with the upper pin hole on the balance beam 1, and the lower pin 42 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com