Jacket lifting and binding process

A jacket and hoisting technology, which is applied in the field of jackets, can solve problems such as difficult and difficult hoisting and barging of the whole jacket of the jacket, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

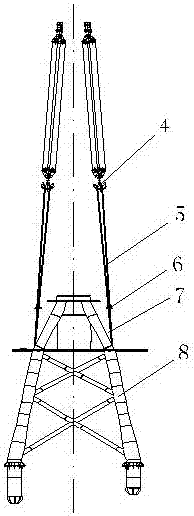

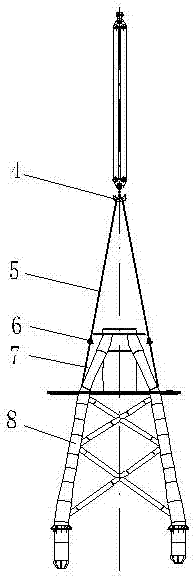

[0032] The fan jacket foundation is divided into three parts: the jacket connection section 81 , the steel platform 82 and the fan jacket main structure 83 . A vertical main cylinder is arranged in the middle of the upper jacket connection section 81. There are four legs on the four sides, a steel platform 82 in the middle, and a main structure 83 in the lower part. The main structure 83 is composed of four main legs and branch pipes. Ship components, ship components have railings, ladders, and additional facilities such as cable J-shaped pipes. Since the weight of the jacket is 400 tons and the volume and weight are relatively large, it is preferred to use barge transportation for its transfer. According to calculation, the lifting distance is required to be 30 meters.

[0033] The specific lifting steps are as follows:

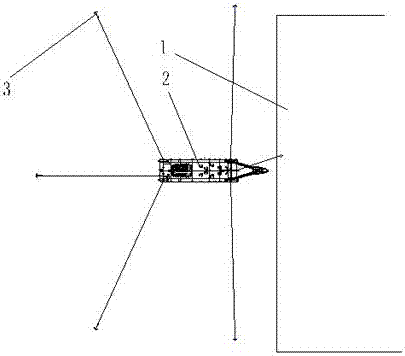

[0034] (1) The approach positioning of the crane ship: if figure 1 As shown, the 600t jib crane ship 2 is selected for hoisting operation. When the inclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com