Burner for external spiral intake volatization and atomization type parking heater with flat cap and necking

A technology of external spiral and heater, which is applied in the direction of engine components, engine starting, machine/engine, etc., can solve the problems of heater thermal efficiency decline, high noise, unfavorable normal combustion of fuel, etc., to improve combustion efficiency and combustion quality, Effects of reducing pollution discharge and heat loss, and avoiding the possibility of carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

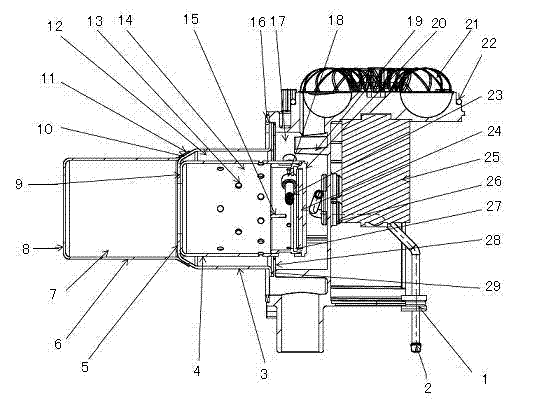

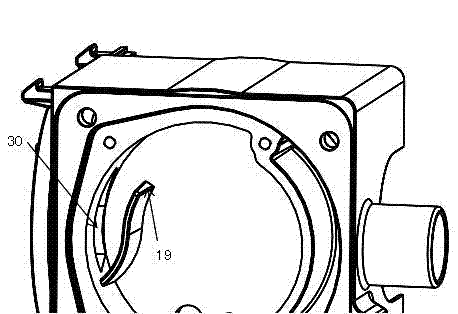

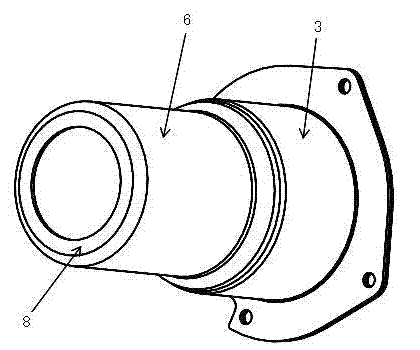

[0029] see Figure 1 to Figure 4 As shown, in the burner for a volatile atomization parking heater with a flat cover, a flat shrinkage, and an external spiral air intake of the present invention, the atomization cylinder 4 and the air preheating cylinder 3 are all stainless steel circular cylinders, and one end is a flat closure. The atomizing cylinder 4 and the air preheating cylinder 3 are socketed together, and the two flat ends are coaxially positioned and connected as a whole; the annular area between the atomizing cylinder 4 and the air preheating cylinder 3 is an air preheating chamber 12. The space inside the atomizing cylinder 4 is the atomizing chamber 14, and two to five rows of small round holes are arranged on the atomizing cylinder 4 as the air inlet holes 13 of the atomizing cylinder, and the prehea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com