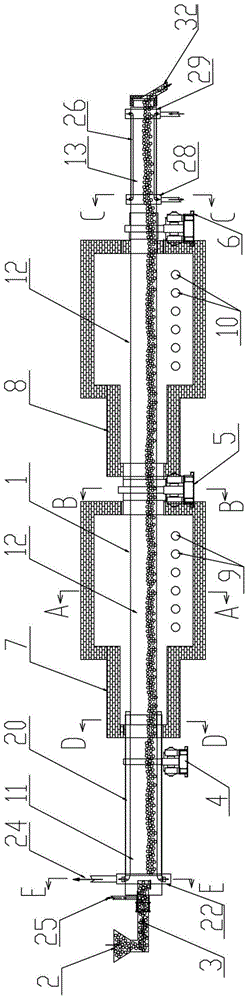

Whole-body type external-heating muffle type rotary kiln

A rotary kiln and external heating technology, which is applied in the direction of rotary drum furnaces, furnaces, furnace types, etc., can solve the problems of small kiln scale, low reduction temperature, and discontinuous temperature in high-temperature areas, and achieve the reduction of temperature required for reduction. The effect of continuous stability and flexible reduction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

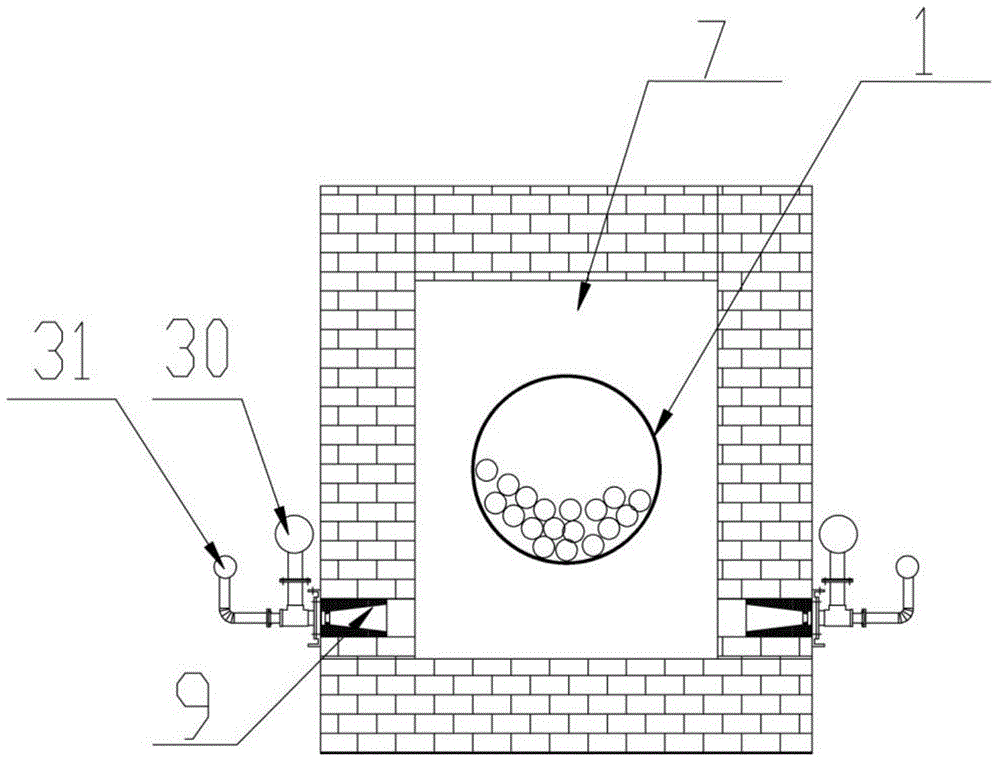

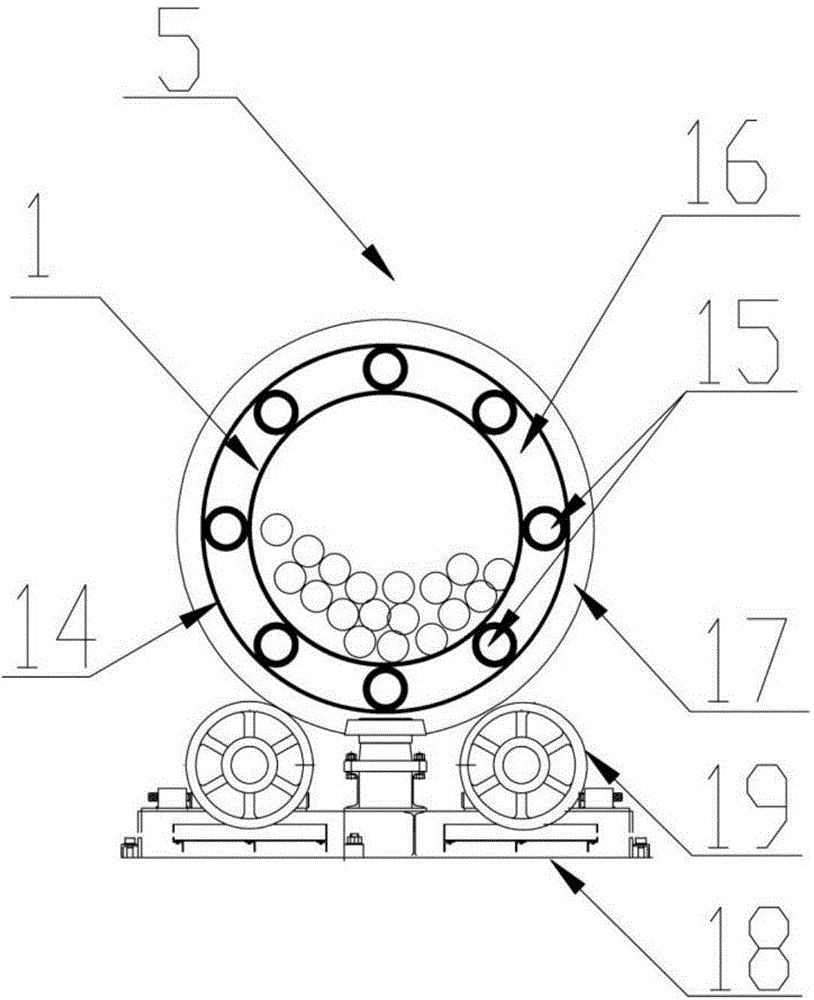

[0037] A kind of flame-trap type rotary kiln with external heating, including a rotary kiln shell 1, a feeding device, a driving device 4, a first support ring device 5 and a second support ring device 6, the special feature is that the rotary kiln shell The body 1 is supported on the drive device 4, the first support ring device 5 and the second support ring device 6, a first heating furnace body 7 is arranged between the drive device 4 and the first support ring device 5, and the A second heating furnace body 8 is arranged between the first supporting ring device 5 and the second supporting ring device 6, and a first burner group is respectively arranged on both sides of the first heating furnace body 7 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com