Preparation method for metal alloy test rod

A metal alloy and test rod technology, applied in the field of metal alloy test rod preparation, can solve the problems of long production cycle, test rod composition deviation and high cost, achieve high uniformity and high accuracy, avoid segregation and loss, The effect of a short melting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

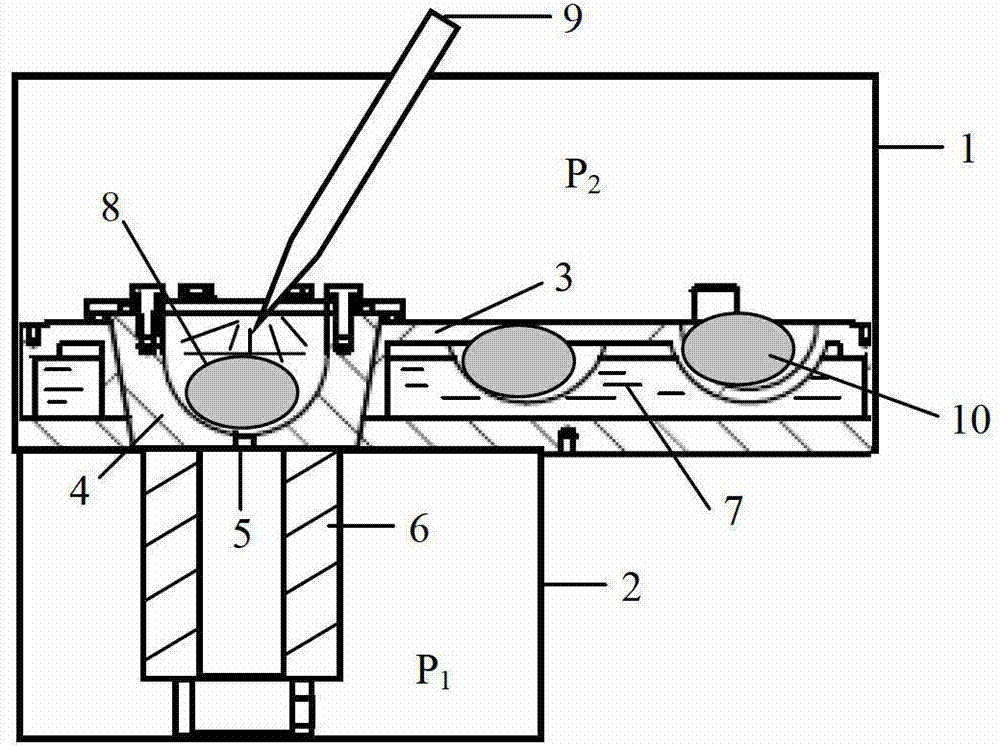

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Preparation of Ti-44.5Al-3Nb-0.6Si (at.%) alloy test rod

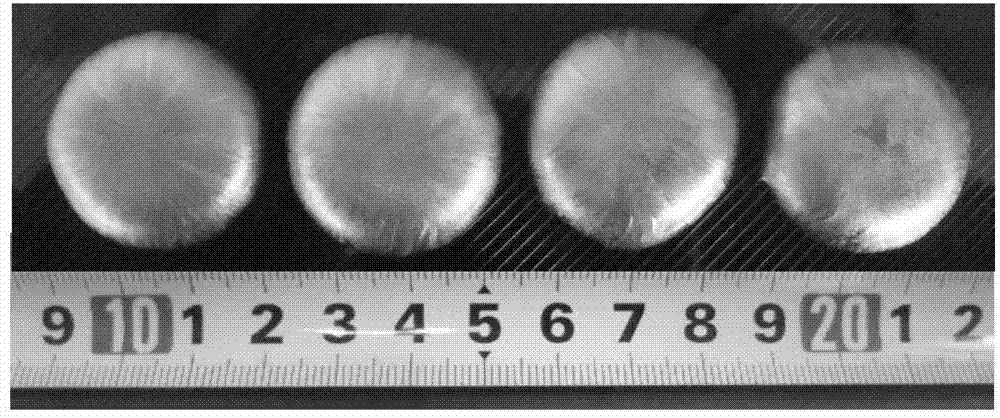

[0033] According to the mass fraction of Ti-44.5Al-3Nb-0.6Si (at.%) alloy components (Ti: 62.29wt.%, Al: 30.21wt.%, Nb: 7.01wt.%, Si: 0.42wt.%) and burning loss compensation law (Ti and Nb are not compensated, Al and Si are both added 0.4%), and high-purity raw materials are used in a certain proportion (Ti:Al:Nb:Si=1:0.49:0.11:0.013) to make 10- 100g alloy bag 10, put it in the copper crucible 3, vacuumize until the vacuum degree reaches 5×10 -3 Above Pa, then inject high-purity argon gas with a pressure of 0.05MPa; start the arc with low current under visual conditions, and gradually increase the melting current to avoid splashing of raw materials, and the low current is 20A; gradually increase the melting current to 200A. Under the assistance of electromagnetic stirring, the alloy bag is melted evenly and thoroughly, and the arc is closed to solidify into a button ingot; then it is turned over and...

Embodiment 2

[0039] The difference from Example 1 is that the alloy bag is placed in the copper crucible 3 of the equipment in the present invention, and the vacuum is evacuated until the degree of vacuum reaches 8×10 -3 Above Pa, then inject high-purity argon gas with a pressure of 0.06MPa; start the arc with low current under visual conditions, and gradually increase the melting current to avoid splashing of raw materials, and the low current is 30A; gradually increase the melting current to 500A. Under the assistance of electromagnetic stirring, the alloy bag is melted evenly and thoroughly, and the arc is closed to solidify into a button ingot; then it is turned over and melted, and this process is repeated 10 times to obtain a button ingot with high purity, high uniformity and high precision, and the button can be seen in the result. The ingot surface is smooth and uniform.

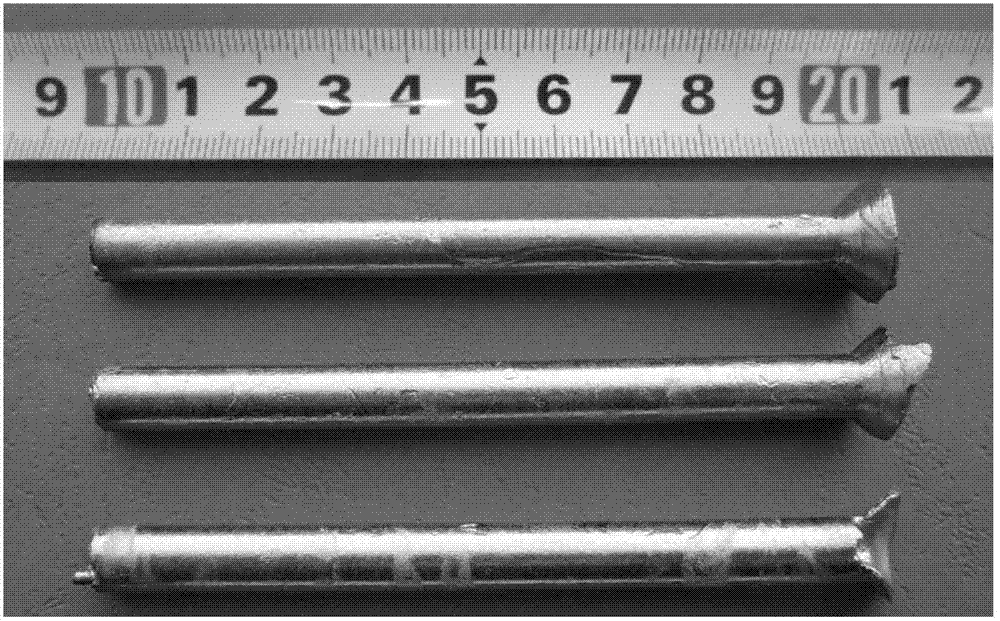

[0040] Put the button ingot into the alloy ingot crucible, place the metal mold of the test rod under the cruci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com