Preparation method of semi-insulating silicon carbide substrate titanium ohmic contact electrode

An ohmic contact electrode, silicon carbide substrate technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of difficult technology acquisition, high cost, and high manufacturing difficulty, reducing the process flow and improving the yield. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific examples.

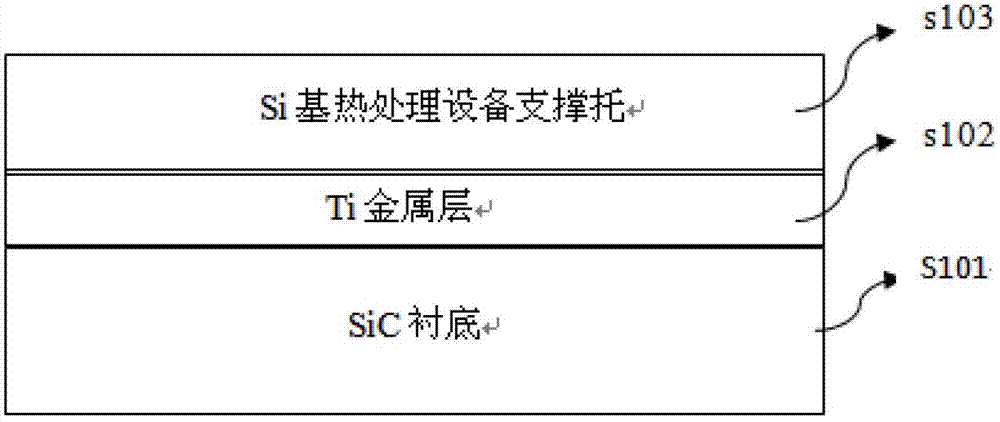

[0034] see Figure 1-Figure 2 , step s101, preparing a SiC wafer as a substrate, with a diameter of 3 inches, double-sided polishing, and carbon-side CMP;

[0035] Step s102, preparing titanium thin film electrodes, that is, using ultra-high vacuum magnetron sputtering equipment, DC target position, 80W, 300°C, 3600s, Ar gas flow 9sccm, deposition chamber pressure 0.45Pa, substrate speed 20r / min, deposition A layer of titanium electrode thin film, the thickness is controlled at 100-140nm.

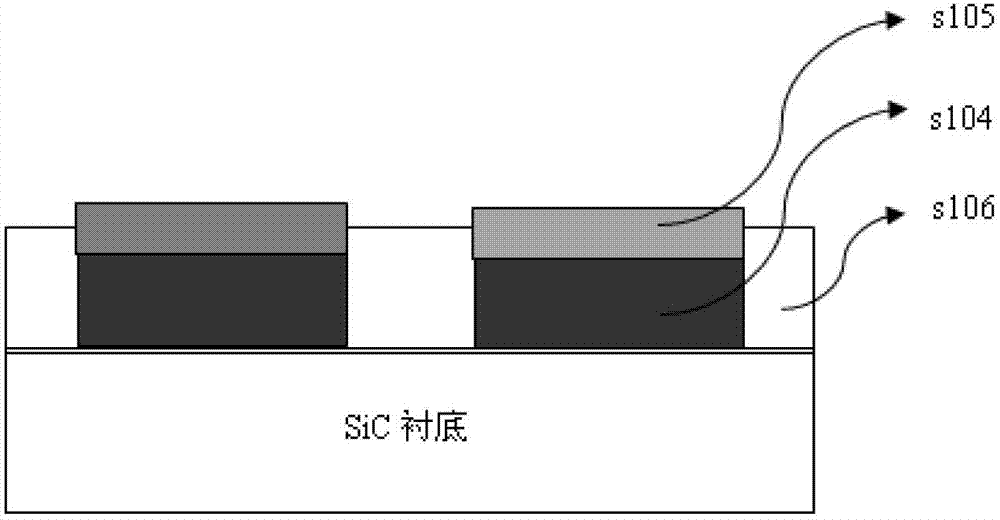

[0036] Step s103, step s104, high-temperature rapid heat treatment: the prepared titanium electrode is attached to the Si supporter of the rapid annealing furnace, and subjected to rapid heat treatment in an Ar atmosphere at 1000°C for 3 minutes to achieve an alloy compound electrode with a gradual change in Si, Ti, and SiC components.

[0037] Step s105, Au protection electrode, that is,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com