PCB board of planar transformer and preparation method thereof

A planar transformer, PCB board technology, applied in the direction of transformer/inductor parts, inductor/transformer/magnet manufacturing, transformer/inductor magnetic core, etc., can solve the problem of low winding efficiency of multi-layer superimposed winding and complicated PCB board process and other problems to achieve the effect of reducing the time for coating the self-adhesive layer, product qualification rate and product consistency guarantee, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

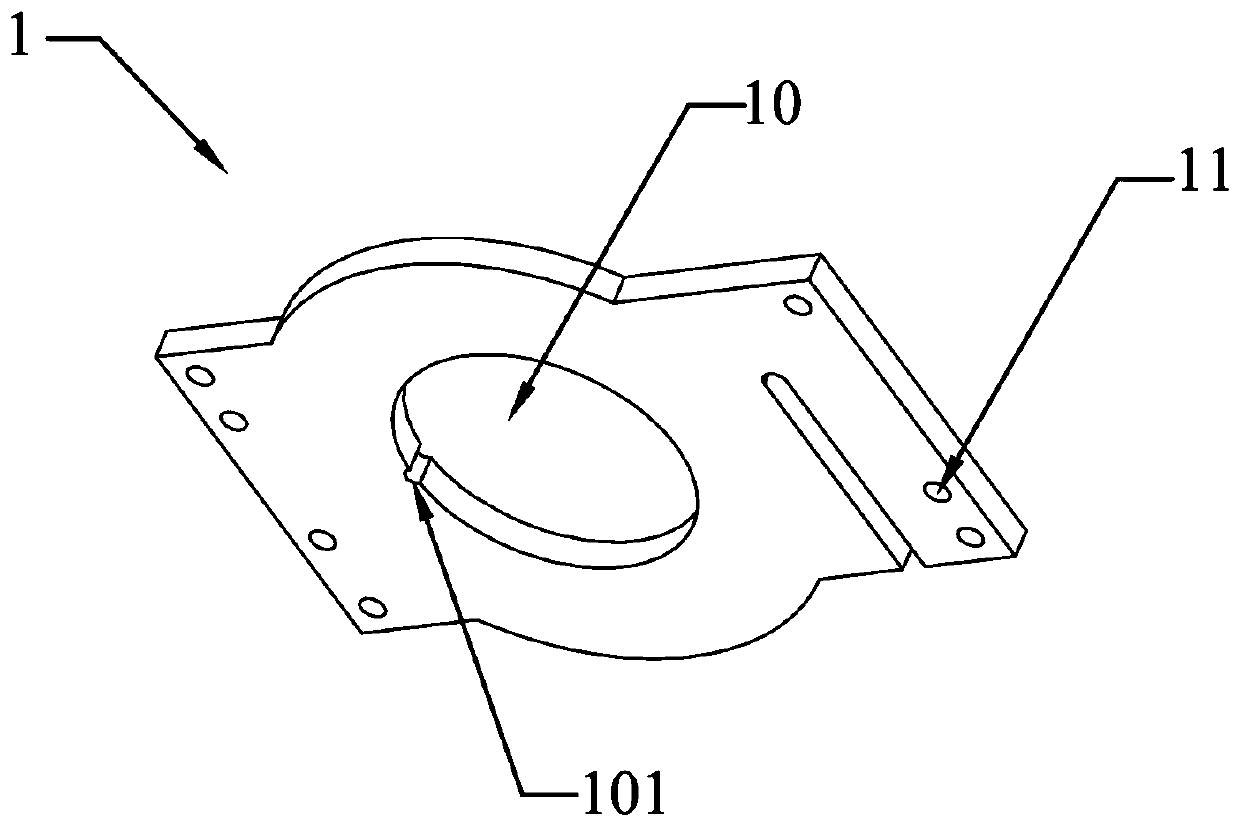

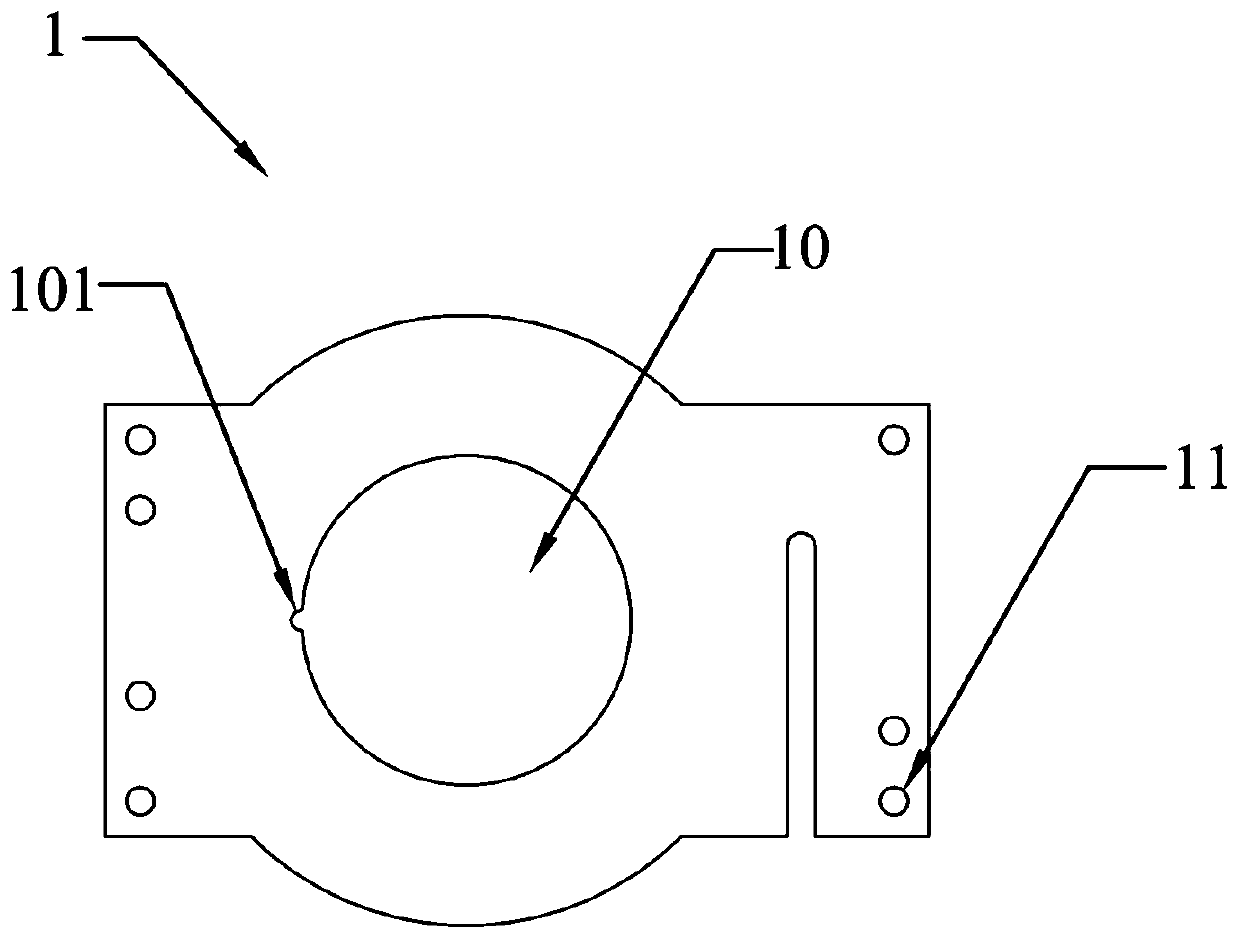

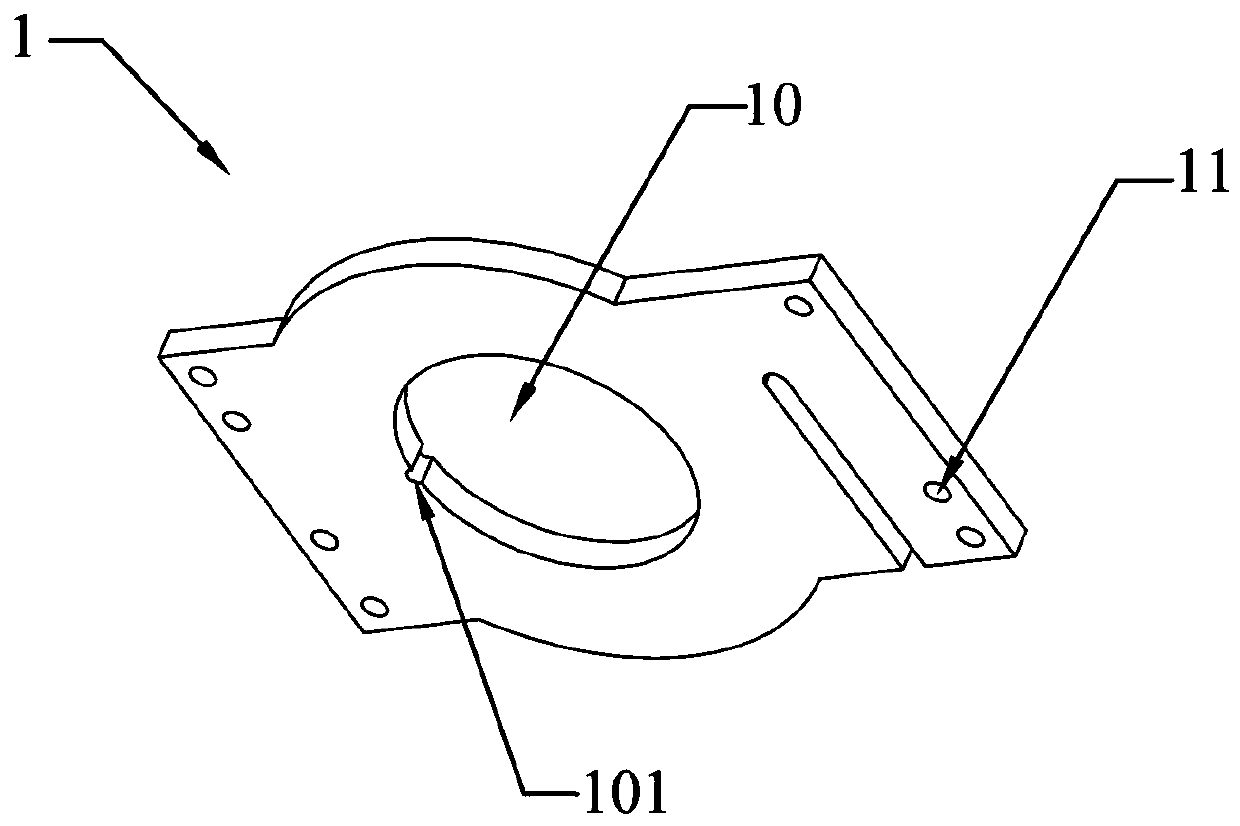

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] The specific embodiment of the present invention proposes a PCB board of a planar transformer, and the planar transformer is mainly applied to a mobile phone fast charging source adapter, and can also be used on a tablet computer and a new energy vehicle power adapter; and the present invention proposes The above-mentioned PCB board does not need to be coated with a self-adhesive layer on the surface, but forms an integrated double-sided winding part on the PCB substrate by colloid injection molding for double-sided plane winding, thereby eliminating the need for self-adhesive coating. The labor cost caused by the self-adhesive layer and a series of problems caused by avoiding the secondary heating of the self-adhesive layer.

[0027] refer to Figure 1 to Figure 7 , the planar transformer PCB board proposed by the specific embodiment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com