Conveying equipment for automated production line for steel grid plates

An automated production line and conveying equipment technology, applied in the field of steel grating manufacturing, can solve the problems of complex equipment, low degree of production automation, and low production efficiency, and achieve the effects of simplifying the operation process steps, ensuring product consistency, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

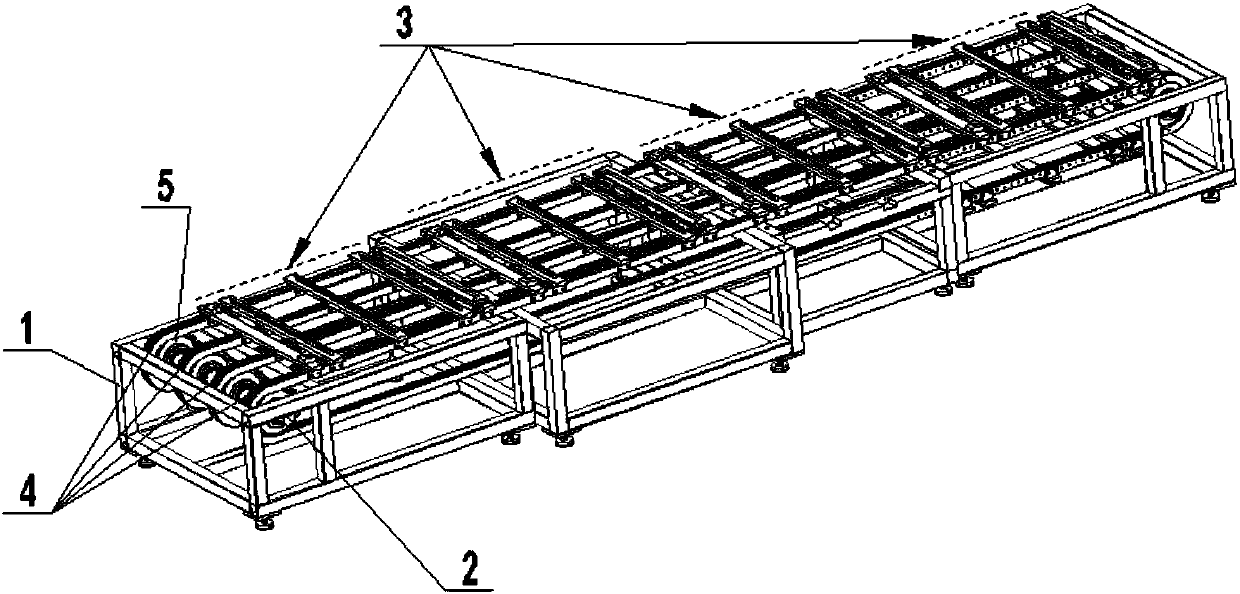

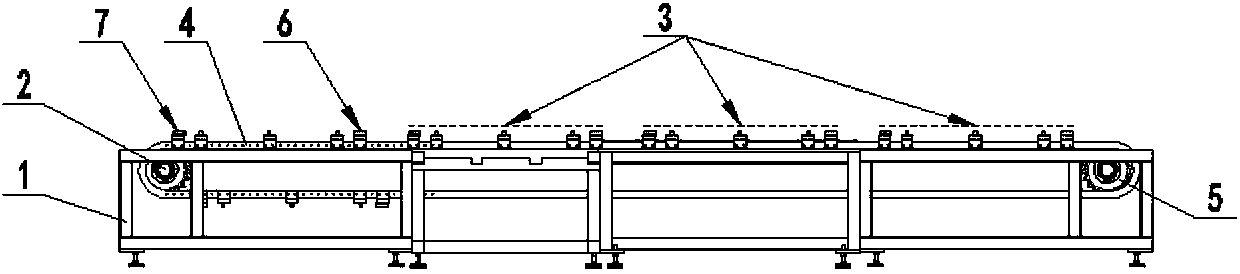

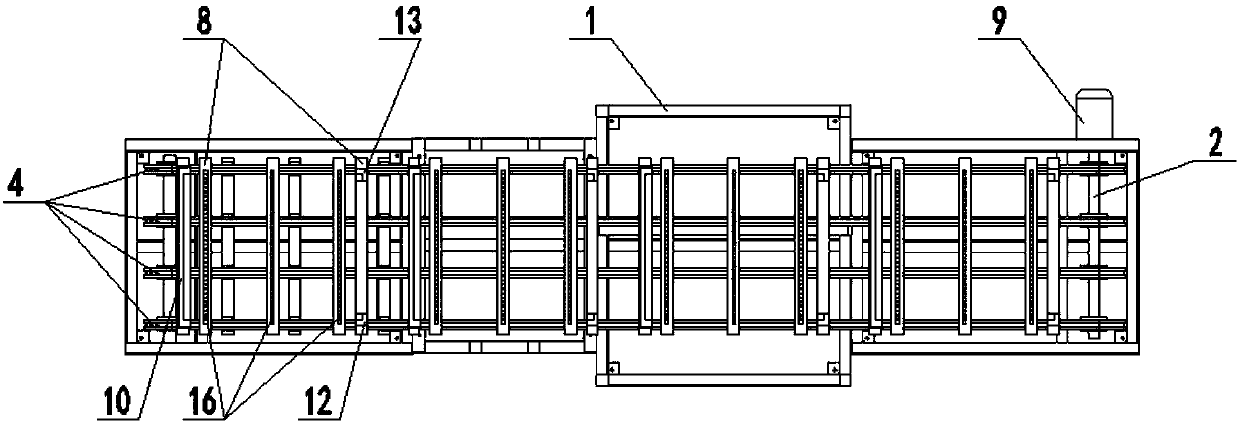

[0030] The invention provides a conveying equipment for steel grating automatic production line, such as Figure 1 to Figure 11 As shown, it includes a frame 1, a drive shaft 2, multiple sets of clamp mechanisms 3 and a plurality of drive belts 4, and the two ends of the drive shaft 2 are installed on both sides of the frame 1 through bearing seats respectively, and each drive shaft 2 is provided with There are a plurality of transmission wheels 5 with the same number, and each transmission belt 4 is meshed with the transmission wheels 5 at the corresponding positions of all transmission shafts 2, and each set of clamp mechanism 3 includes a limiting device A6, a limiting device B7 and at least two clamps The support plate 8, each clamp support plate 8 is installed on the transmission belt 4, and the limit device A6 and the limit d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com