Welding tool for cabin accessory support assembly

A welding tooling and bracket assembly technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as inability to perform batch welding, affect production progress, and huge labor costs, so as to ensure welding quality and The effect of product consistency, improving welding efficiency and saving post resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

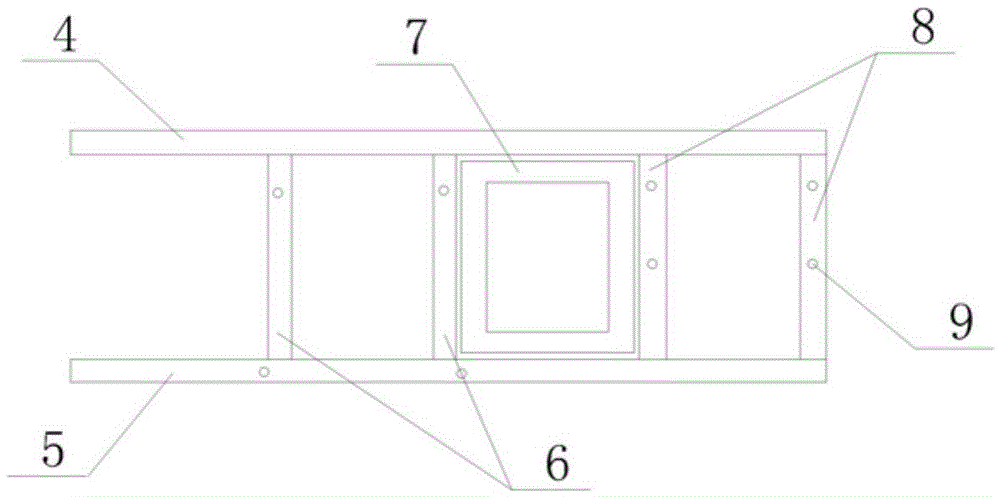

[0015] Such as figure 1 As shown, a complete engine room accessory bracket assembly usually includes an accessory bracket upper beam 4 , an accessory bracket lower beam 5 , a high voltage distribution box bracket 6 , a battery bracket 7 and an air conditioner compressor bracket 8 . Each component is also provided with several mounting positioning holes 9 .

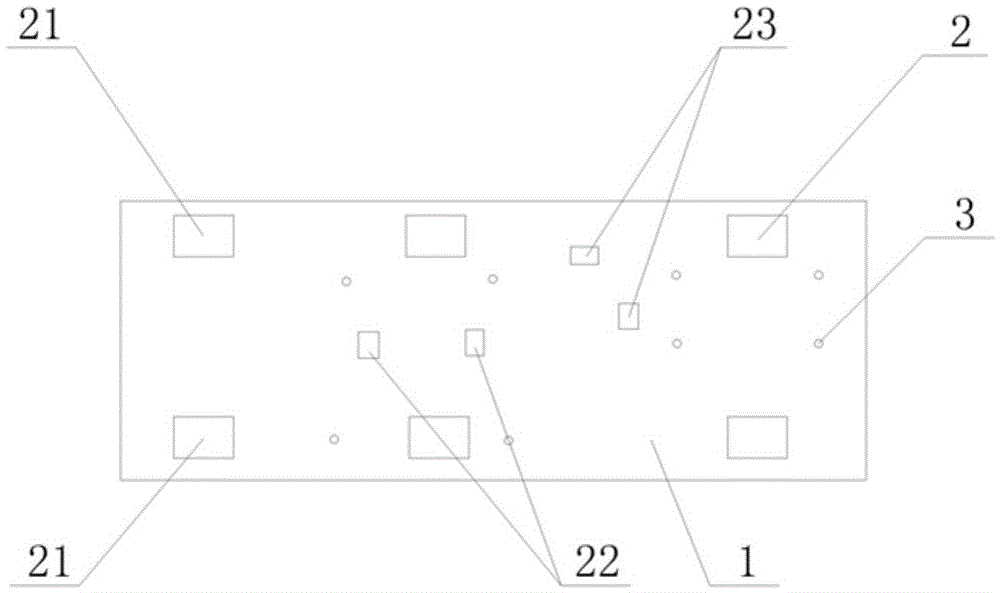

[0016] Such as figure 2 As shown in the figure, it is a welding tool designed to complete the welding assembly of various parts on the accessory bracket assembly of the engine room. The welding tool structure provided in this embodiment mainly includes a main body 1 of the welding tool. The main body 1 of the welding tool is a rectangular aluminum alloy plate on which a plurality of positioning angle irons 2 and positioning pins 3 are installed. The position of the positioning angle iron 2 matches the edge of the corresponding part. The positioning angle iron 2 includes a bracket beam fixing angle iron 21 , a high volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com