Processing technology of tensile composite conductor for cable and composite conductor

A processing and composite technology, which is used in cable/conductor manufacturing, metal/alloy conductors, and reducing the size of conductors/cables. , There are difficulties in large-length manufacturing, so as to ensure the consistency of appearance quality and outer diameter, the processing process is simple and practical, and the outer diameter control effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

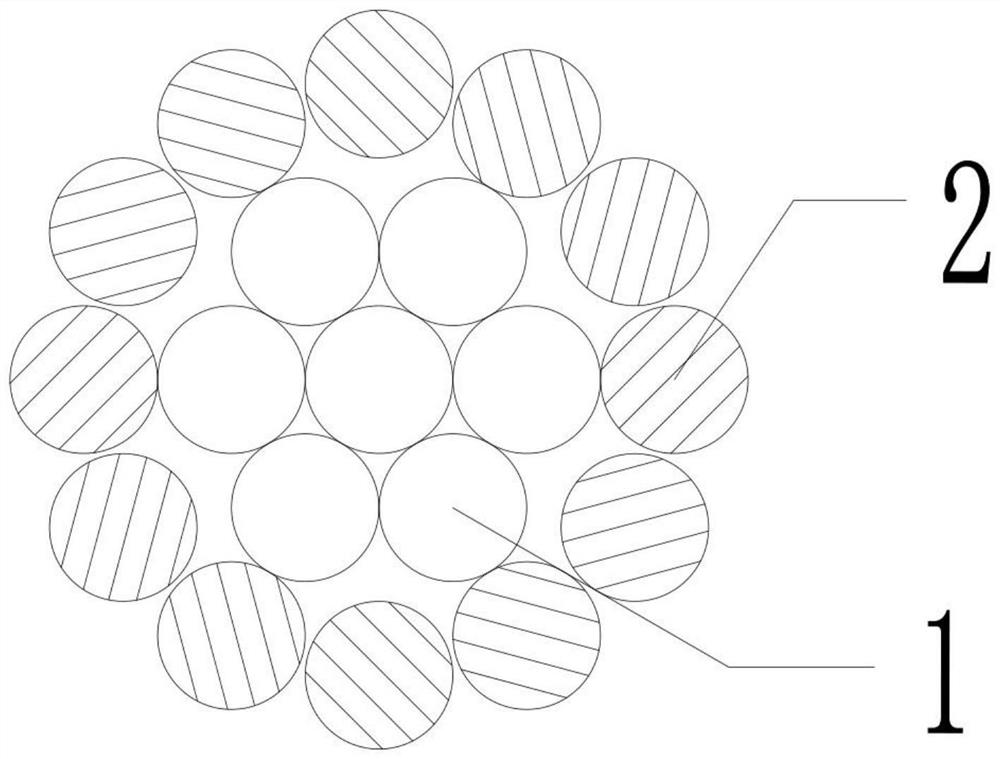

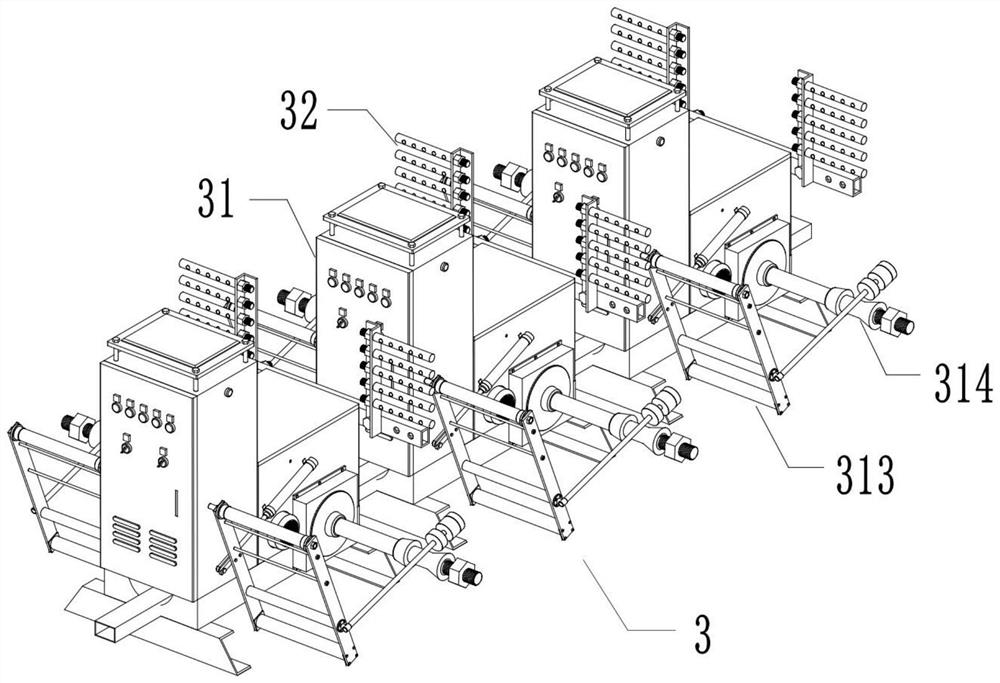

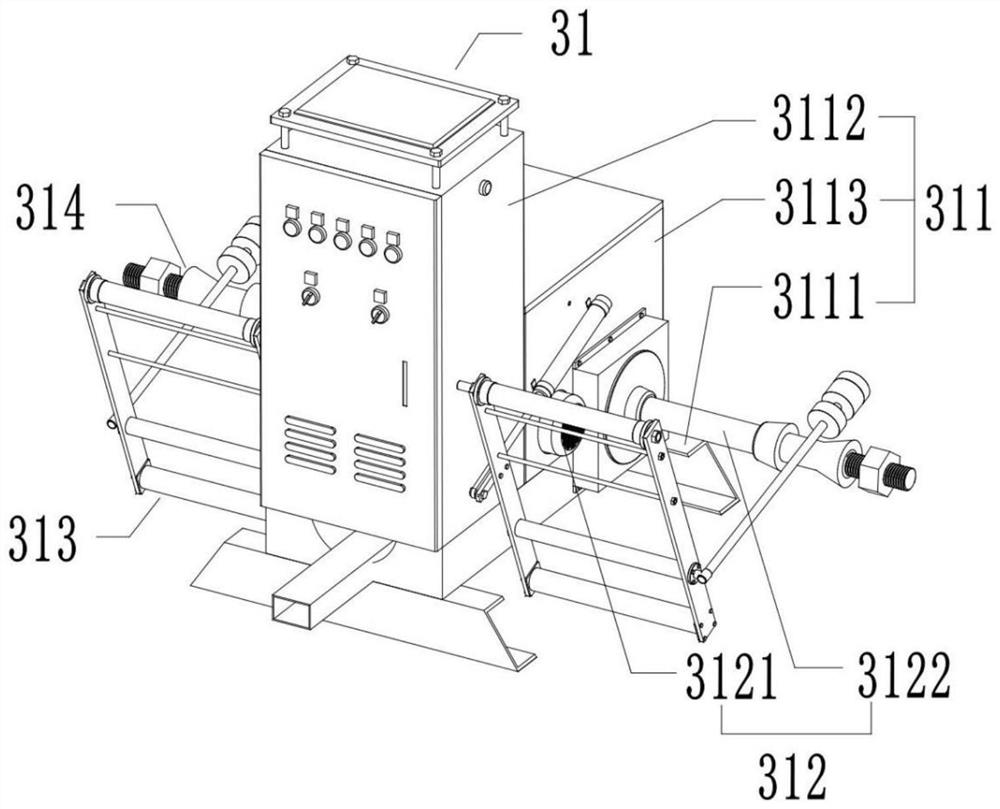

[0069] Such as figure 1 As shown in Fig. 1, a processing technology for tensile composite conductors for cables, including stranding treatment and annealing treatment, the stranding treatment adopts 19 strands or 37 strands of regular stranding, and arranges them in 3 layers through layered abnormal pay-off racks Aluminum alloy monofilament 1 and copper monofilament 2 supply twisted wires for the stranding machine, which are twisted into a conductor whose inner layer is aluminum alloy monofilament 1 and outer layer is copper monofilament 2, wherein the layered The different-moving pay-off frame 3 controls the different tensions of each layer of monofilament pay-off.

[0070] At the same time, according to the cross-sectional area specification of the composite conductor that needs to be processed, when the cross-section is small, the regular stranding method of 19 strands (ie 1+6+12) is adopted, and the inner layer is aluminum alloy monofilament 1 and the outermost layer is C...

Embodiment 2

[0117] Such as figure 1 As shown, the difference from Example 1 is that the aluminum alloy monofilament 1 is prepared by the following method:

[0118] S1: Smelting, put the aluminum ingot and the alloy mixed material into the smelting device for smelting to obtain molten aluminum alloy, wherein the mass fraction of each element of the alloy mixed material is: Si=0.10%, Fe=0.5%, Cu=0.2%, Mg=0.05%, Zn=0.05%, B=0.02%, the rest are Al and unavoidable trace impurities, and the total content of impurity elements is 0.08%, in addition, the mass fraction of Li element is 0.03%, and the mass fraction of Ga element 0.03%;

[0119] S2: Casting, introducing the molten aluminum alloy into the casting device for casting to obtain aluminum alloy rods;

[0120] S3: Rolling, rolling the aluminum alloy rod into an aluminum alloy rod;

[0121] S4: Wire drawing, so that the aluminum alloy rod is drawn into an aluminum alloy monofilament 1 through multiple wire drawing equipment such as a larg...

Embodiment 3

[0125] Such as figure 1 As shown, the difference from Example 2 is that in the preparation of the aluminum alloy monofilament 1, the step S1: smelting, the aluminum ingot and the alloy mixed material are put into the smelting device for smelting to obtain the molten aluminum alloy, wherein the alloy mixed The mass fraction of each element of the material is: Si=0.05%, Fe=0.6%, Cu=0.2%, Mg=0.03%, Zn=0.03%, B=0.005%, the rest are Al and unavoidable trace impurities, and the impurities The total element content is 0.085%, and the mass fraction of Li element is 0.03%, and the mass fraction of Ga element is 0.03%.

[0126] Further, the stranded conductor is annealed at a high temperature of 350°C for 6 hours to obtain a composite conductor. After annealing, the tensile strength of the composite conductor reaches 300MPa, and the elongation at break can reach more than 15%, which is better than that of aluminum Alloy stranded conductors and copper stranded conductors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com