Quantitative glue dispenser

A dispensing machine and dispensing device technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems affecting the production consistency of in-line LEDs, unbalanced in-line LED dispensing, and in-line LED dispensing. Type LED quality problems and other problems to achieve the effect of ensuring production consistency, avoiding quality problems, and keeping materials neat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

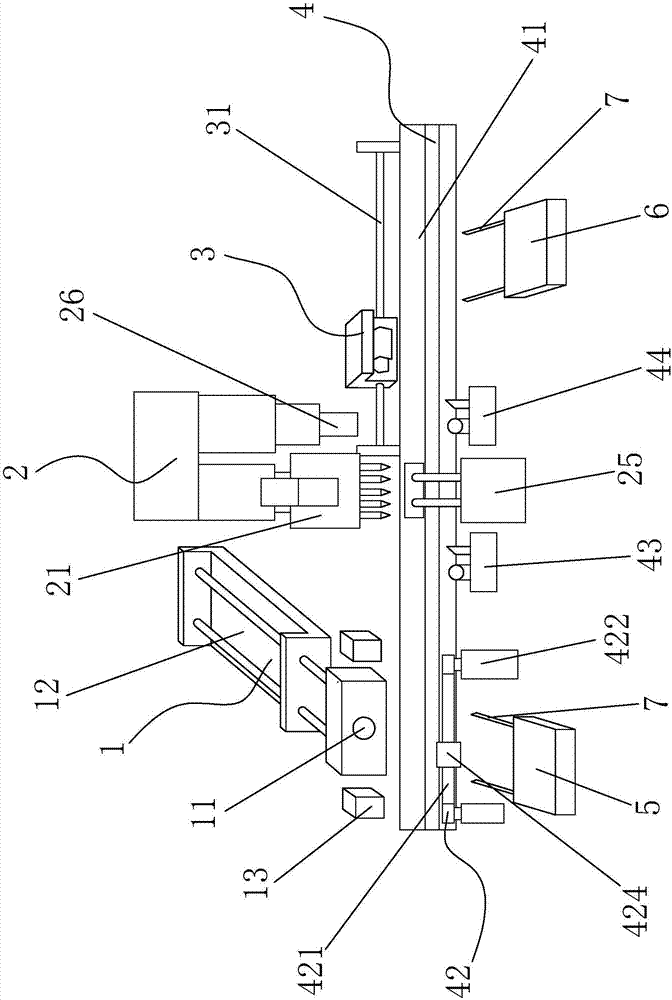

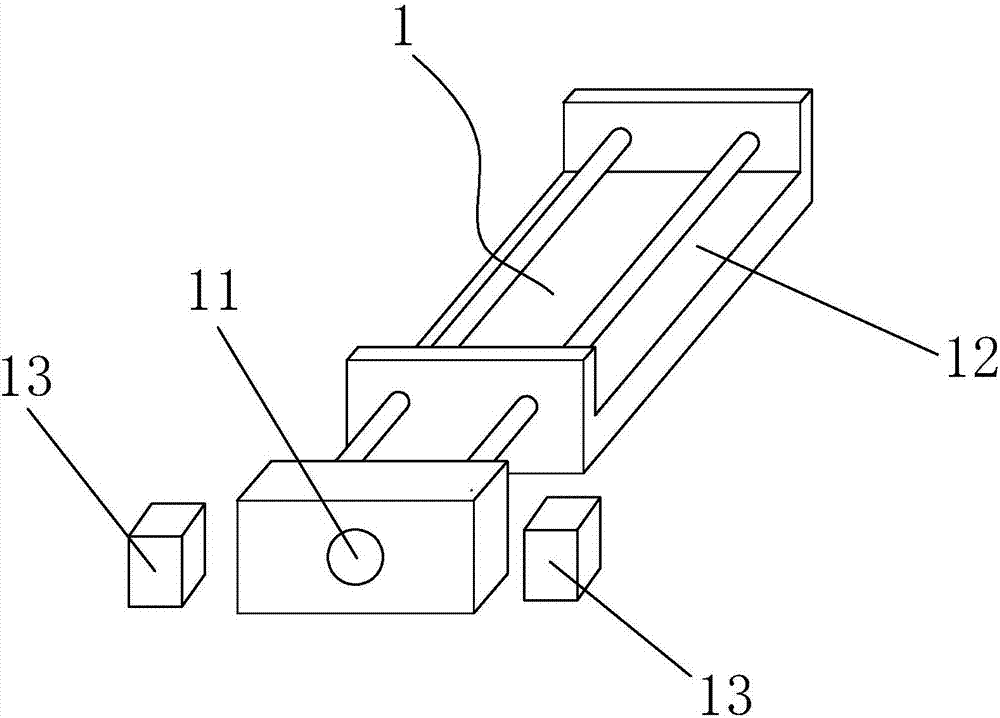

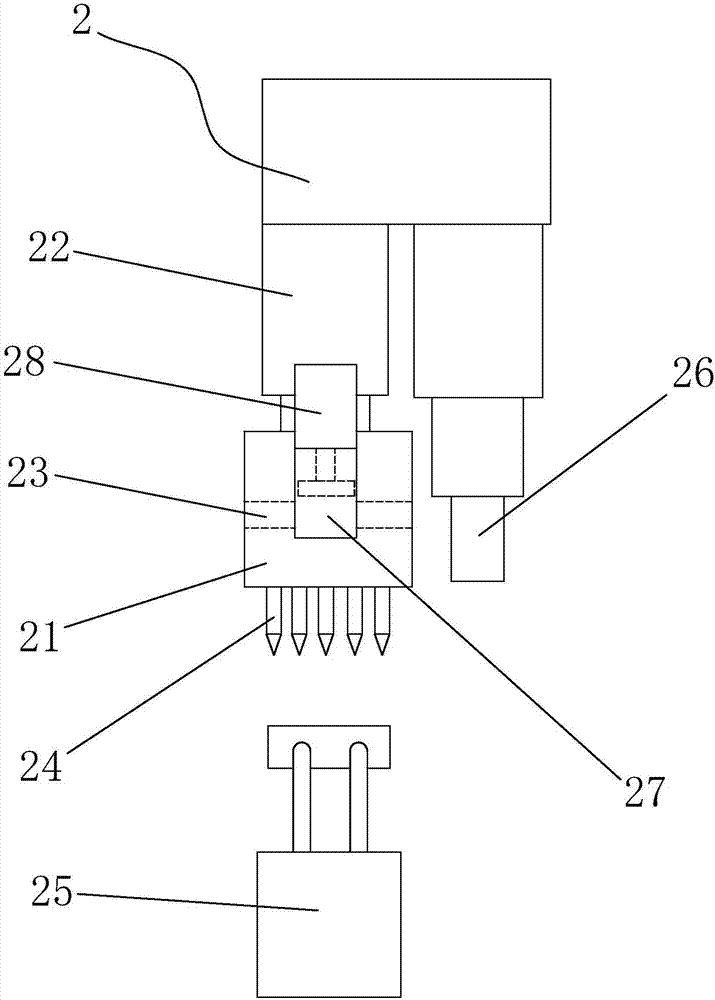

[0022] refer to Figure 1-Figure 5 , a kind of quantitative dispensing machine of the present invention comprises a dispensing machine body, and the dispensing machine body includes a material retrieving device 1 for placing materials in the dispensing machine body, a device for quantitative dispensing of materials The dispensing device 2, the unloading device 3 for taking the material out of the dispensing machine body and the conveying device 4 for conveying the material, the retrieving device 1, the dispensing device 2 and the unloading device 3 are respectively along the The transmission path of the transmission device 4 is set. The glue dispensing device 2 includes a glue injection module 21 for placing the glue to be injected. The glue injection module 21 is provided with a glue injection motor 22 for quantitatively outputting the glue. The glue injection motor An injection block 23 is arranged on the rotating shaft of 22 , and the injection motor 22 drives the injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com