Negative pressure hollow glass and preparation method thereof

A glass and hollow technology, which is applied in the field of negative pressure insulating glass and its production, can solve the problems of complex structure of air exhaust port and air valve, affecting the service life of insulating glass, bonding strength and airtightness damage, and is beneficial to automation The effect of continuous production line, promotion of industrial production, reduction of self-explosion rate and breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

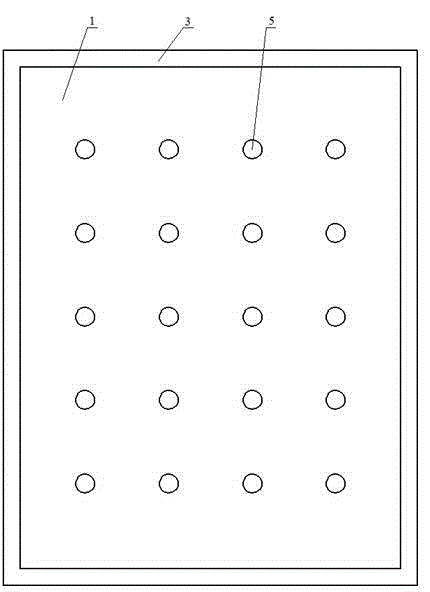

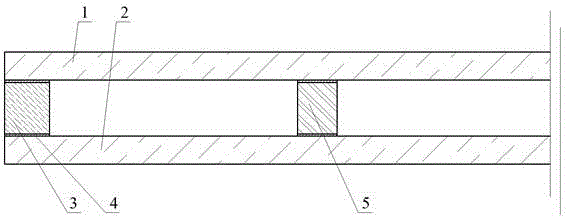

[0028] Example: see figure 1 and figure 2 , a negative pressure insulating glass, consisting of upper glass 1, lower glass 2 and frame 3, two pieces of glass are tempered glass, one of which is low-emissivity glass; the periphery of the two pieces of glass is sealed by frame 3 and ultraviolet curing glue 4 Connected together, the middle is a negative pressure hollow layer. The production method is as follows: First, cut two pieces of flat glass according to the shape and size of the negative pressure insulating glass to be produced, and perform edge grinding, chamfering, cleaning and drying, and then send the two pieces of glass into the tempering furnace respectively Carry out tempering treatment; according to the shape and size of the two pieces of glass, prepare 4 pieces of glass strips to form a frame 3, select a glass disc or cylinder with the same thickness as a support 5, and the thickness of the negative pressure hollow layer is the same as that of the existing hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com