Integral lifting type formwork device for an elevator shaft

A technology of overall lifting and elevator shaft, which is applied in the fields of formwork/template/work frame, on-site preparation of building components, construction, etc., which can solve the problems of high potential safety hazards, labor-intensive and labor-intensive problems, save manpower and material resources, improve technology Performance, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

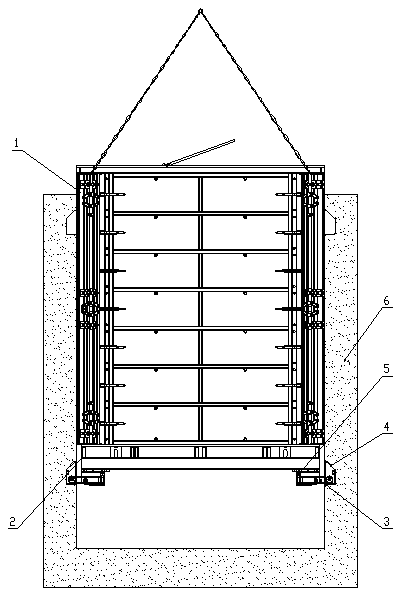

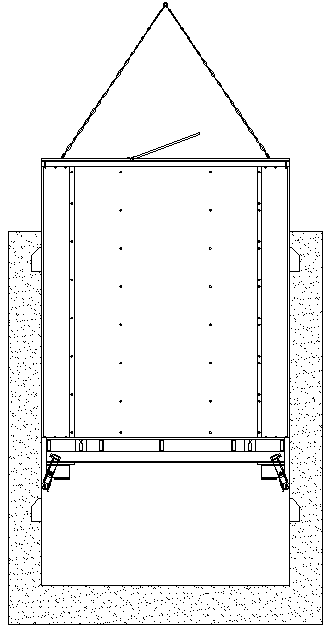

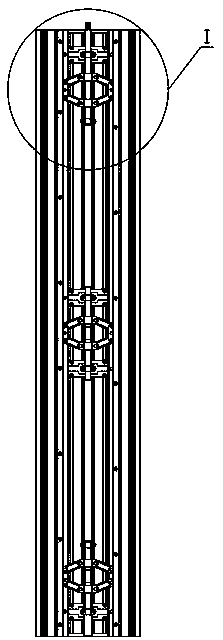

[0021] The present invention provides an elevator shaft overall lifting formwork device, which includes a core tube 1 with a rectangular parallelepiped structure. The four sides of the core tube 1 are all side plates 10 with flat surfaces. The upright column 22 with a right triangle cross section and the side plate 10 form a cuboid structure with a square cross section. The outer surfaces of two adjacent side plates 10 are respectively flush with the two side faces of the column 22, and the interior of the column 22 is longitudinally provided with some shrinking devices that allow the side plates 10 to move along the inner edge of the column 22, and the bottom of the column 22 It is movably connected with the base 2 of the core tube 1. Below the base 2, there are several claw seats 3 that are connected with the preset latch box 4 inside the wall 6. The claw seats 3 support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com