Prestressed partially-encased steel T-shaped composite beam and construction method thereof

A technology of prestressed and composite beams, which is applied in the direction of load-bearing elongated structural components, structural elements, building components, etc., can solve the problems of small component cross-section size, complex construction, and small self-weight, so as to improve beam stiffness, The effect of simplifying the construction process and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

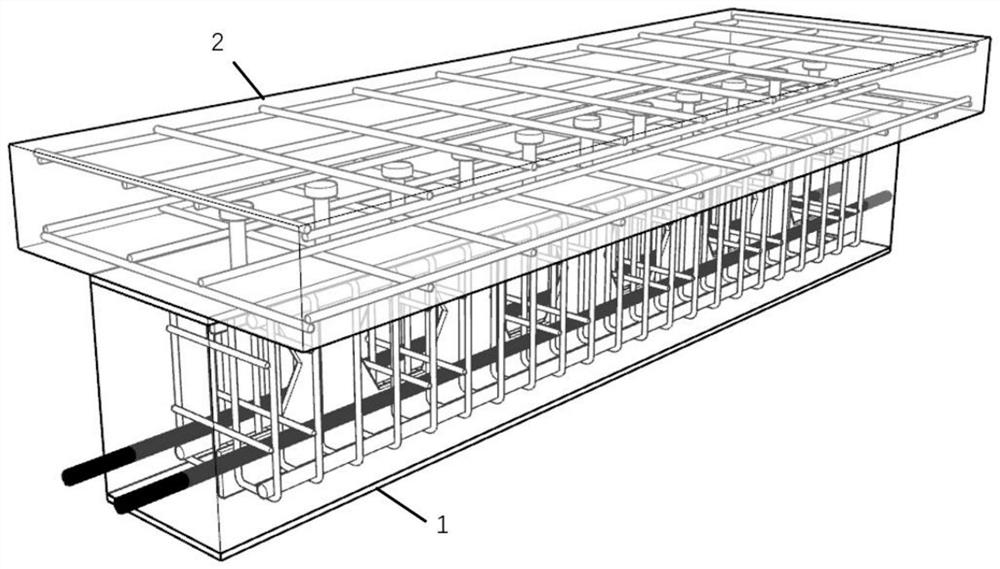

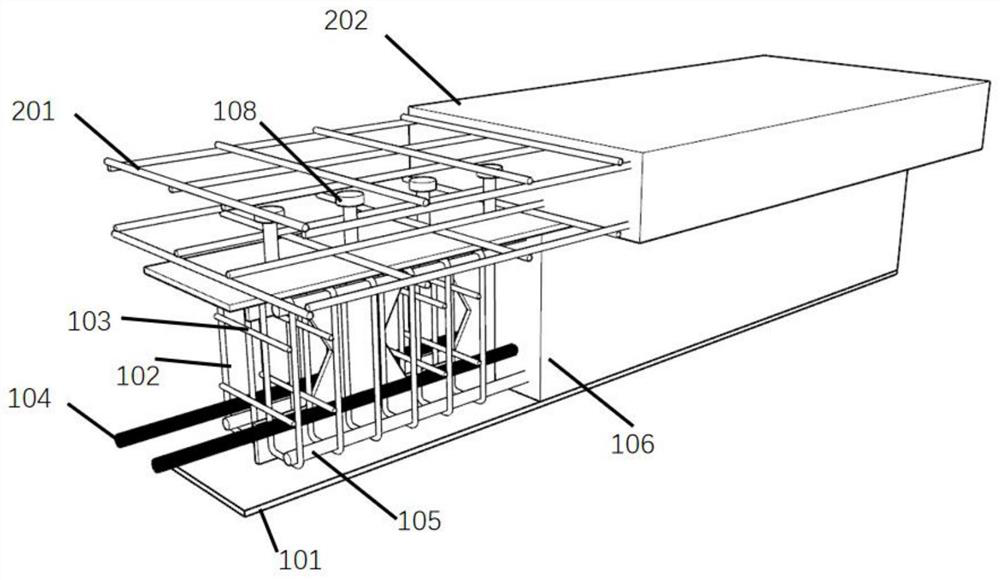

[0046] A prestressed partially outsourced steel T-shaped composite beam, based on prestressed prefabricated assembly technology, has excellent mechanical performance, can significantly improve the crack resistance and bending stiffness of the beam, and is convenient for on-site construction and shortens the construction period. Such as figure 1 As shown, it is mainly composed of prestressed prefabricated rectangular composite beam 1 and cast-in-place concrete flange plate 2.

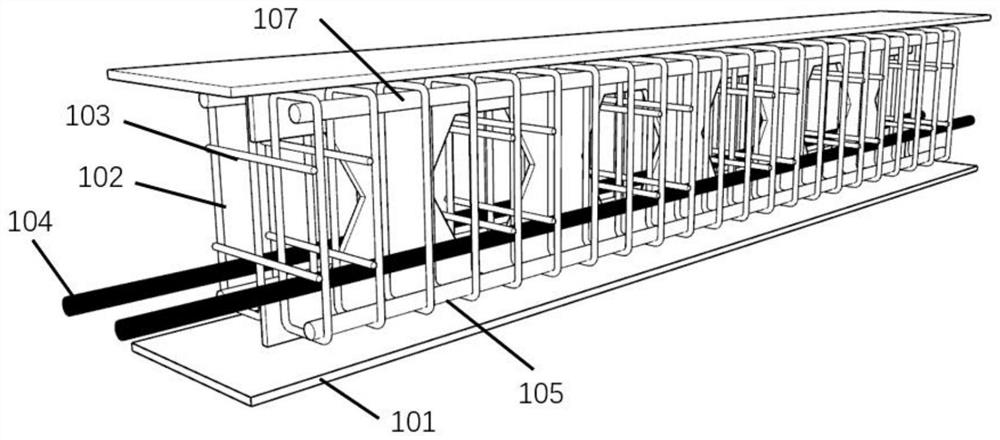

[0047] refer to figure 2 , image 3 , Figure 4 , the prestressed prefabricated rectangular composite beam 1 includes: honeycomb steel 101, several closed stirrups 102, several tie bars 103, several longitudinal reinforcements 105, several longitudinal reinforcements 107, several prestressed steel strands 104, prefabricated ultra-high performance concrete 106 and seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com