Auxiliary device for binding reinforcements of reinforced concrete beam and application thereof

A technology of reinforced concrete beams and auxiliary devices, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of safety, low reliability, inconvenient operation, instability, etc., and achieve high social and economic benefits. , Reduce the waste of resources, the effect of stable and reliable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

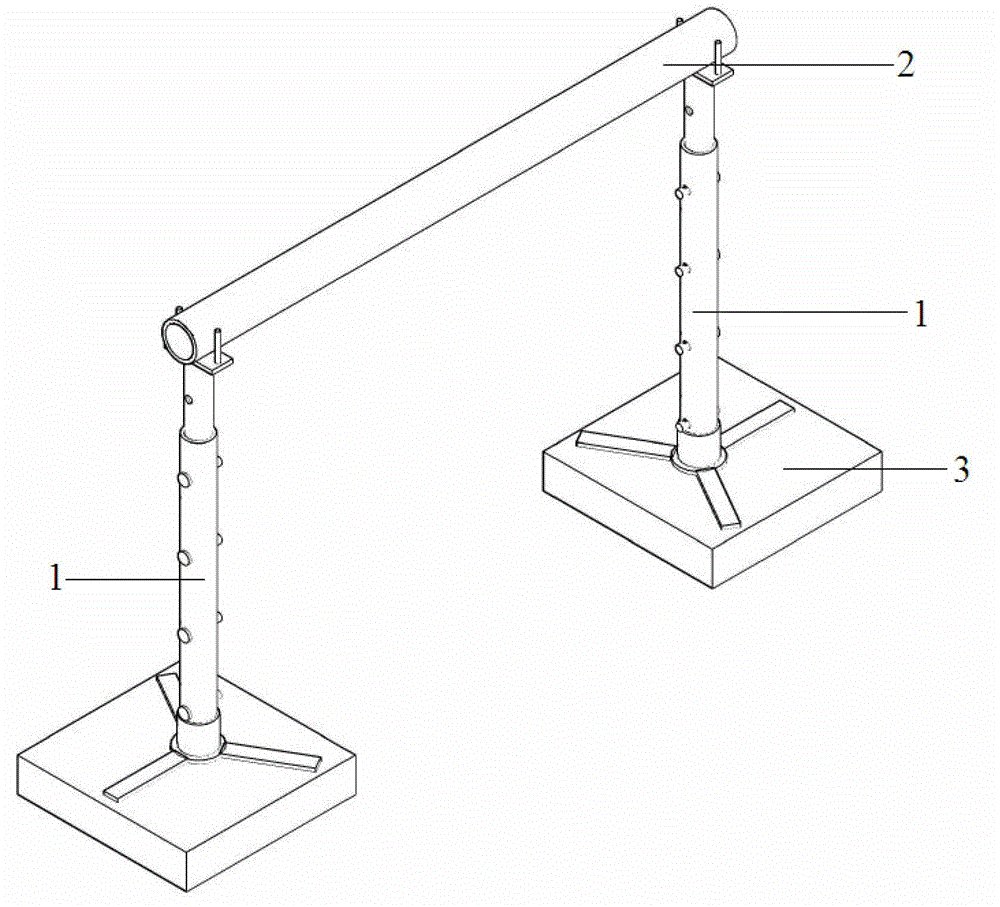

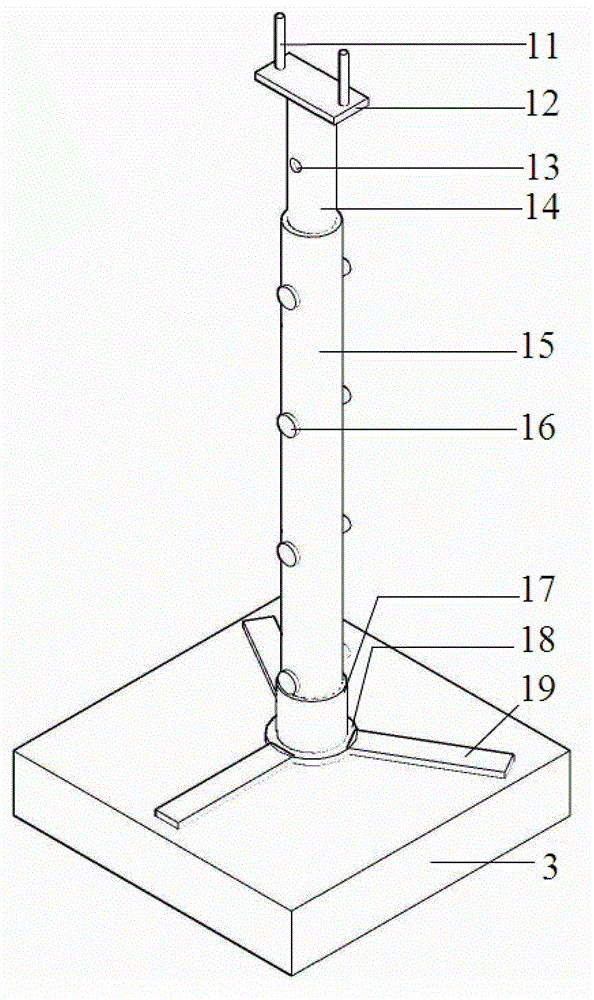

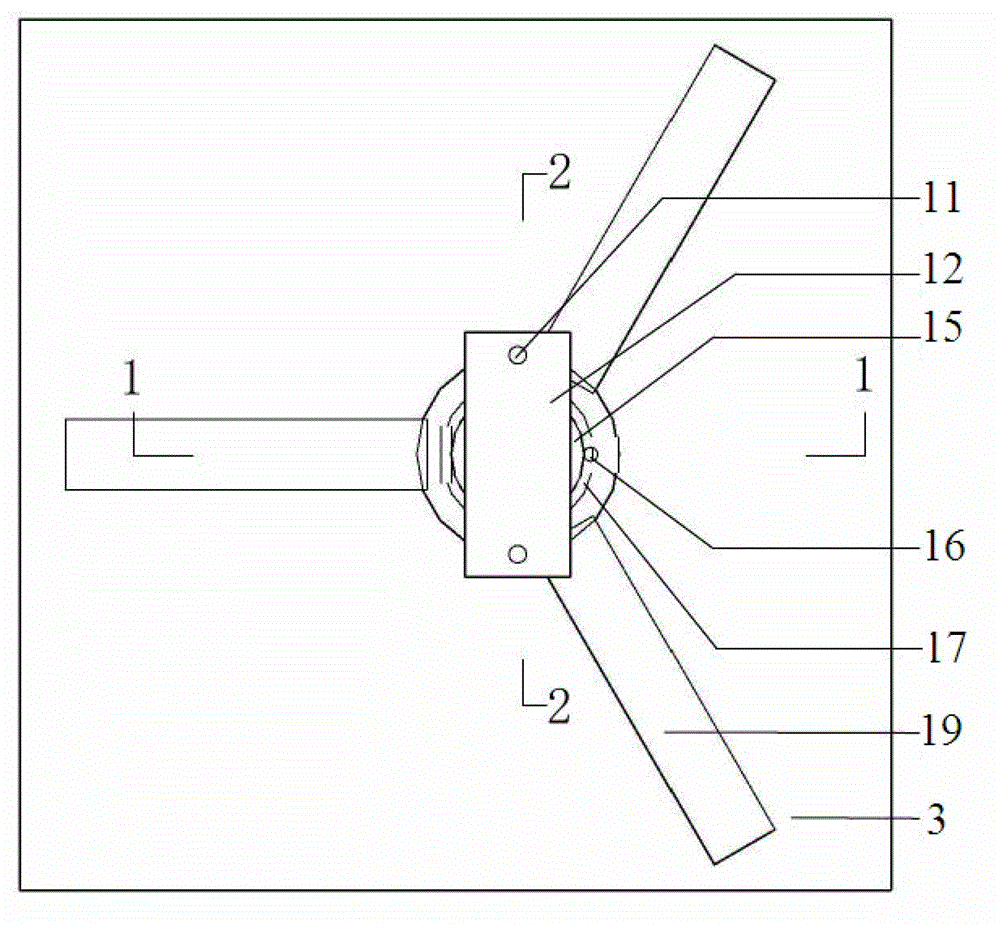

[0037] An auxiliary device for binding steel bars of reinforced concrete beams, the structure of which is as Figure 1 to Figure 5 As shown, the auxiliary device includes two brackets 1 arranged side by side and a cross bar 2 overlapped on the two brackets 1 , and the bracket 1 is a telescopic bracket 1 . The bracket 1 includes an inner tube 14 and an outer tube 15, the inner tube 14 is inserted into the outer tube 15 and is telescopically connected with it, the lower end of the outer tube 15 is provided with a fixing piece, the upper end of the inner tube 14 is provided with a joint base, and a cross bar 2 lapped on the docking base. Both the inner tube 14 and the outer tube 15 are provided with a plurality of through holes 13 along the length thereof, and the specifications and positions of the through holes 13 of the inner tube 14 are consistent with those of the outer tube 15 . The inner tube 14 is connected to the outer tube 15 by inserting the pin 16 into the through ho...

Embodiment 2

[0047] An auxiliary device for binding steel bars of reinforced concrete beams, the structure of which is as Figure 1 to Figure 5 As shown, the auxiliary device includes two brackets 1 arranged side by side and a cross bar 2 overlapped on the two brackets 1 , and the bracket 1 is a telescopic bracket 1 . The bracket 1 includes an inner tube 14 and an outer tube 15, the inner tube 14 is inserted into the outer tube 15 and is telescopically connected with it, the lower end of the outer tube 15 is provided with a fixing piece, the upper end of the inner tube 14 is provided with a joint base, and a cross bar 2 lapped on the docking base. Both the inner tube 14 and the outer tube 15 are provided with a plurality of through holes 13 along the length thereof, and the specifications and positions of the through holes 13 of the inner tube 14 are consistent with those of the outer tube 15 . The inner tube 14 is connected to the outer tube 15 by inserting the pin 16 into the through hole...

Embodiment 3

[0057] An auxiliary device for binding steel bars of reinforced concrete beams, the structure of which is as Figure 1 to Figure 5 As shown, the auxiliary device includes two brackets 1 arranged side by side and a cross bar 2 overlapped on the two brackets 1 , and the bracket 1 is a telescopic bracket 1 . The bracket 1 includes an inner tube 14 and an outer tube 15, the inner tube 14 is inserted into the outer tube 15 and is telescopically connected with it, the lower end of the outer tube 15 is provided with a fixing piece, the upper end of the inner tube 14 is provided with a joint base, and a cross bar 2 lapped on the docking base. Both the inner tube 14 and the outer tube 15 are provided with a plurality of through holes 13 along the length thereof, and the specifications and positions of the through holes 13 of the inner tube 14 are consistent with those of the outer tube 15 . The inner tube 14 is connected to the outer tube 15 by inserting the pin 16 into the through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com