Segmented self-traveling type cast-in-place beam hydraulic inner mould and mould erecting and demoulding method thereof

A cast-in-place beam, self-propelled technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of high labor intensity, low efficiency, poor working environment, etc., and achieve good overall stability and good economy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with drawings and embodiments.

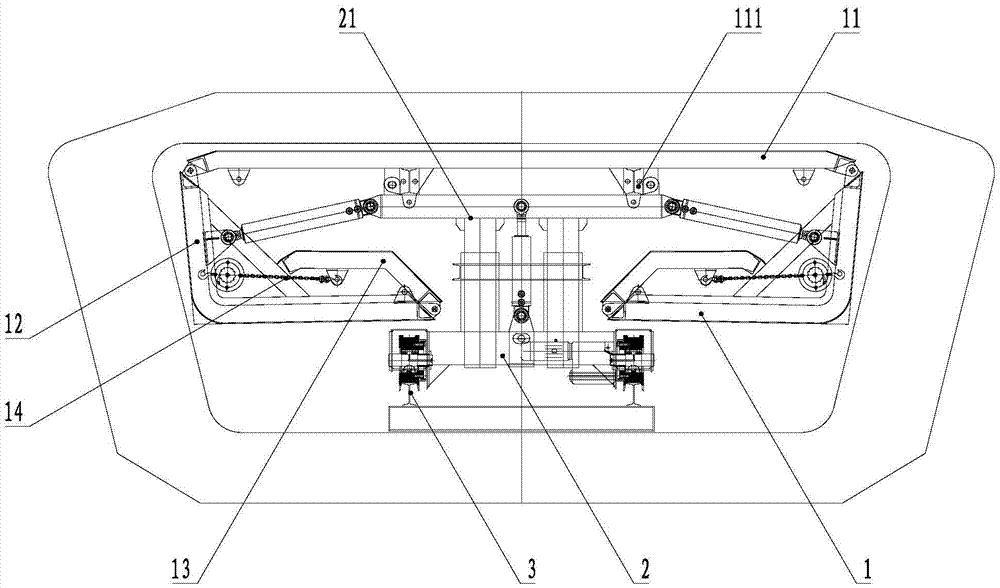

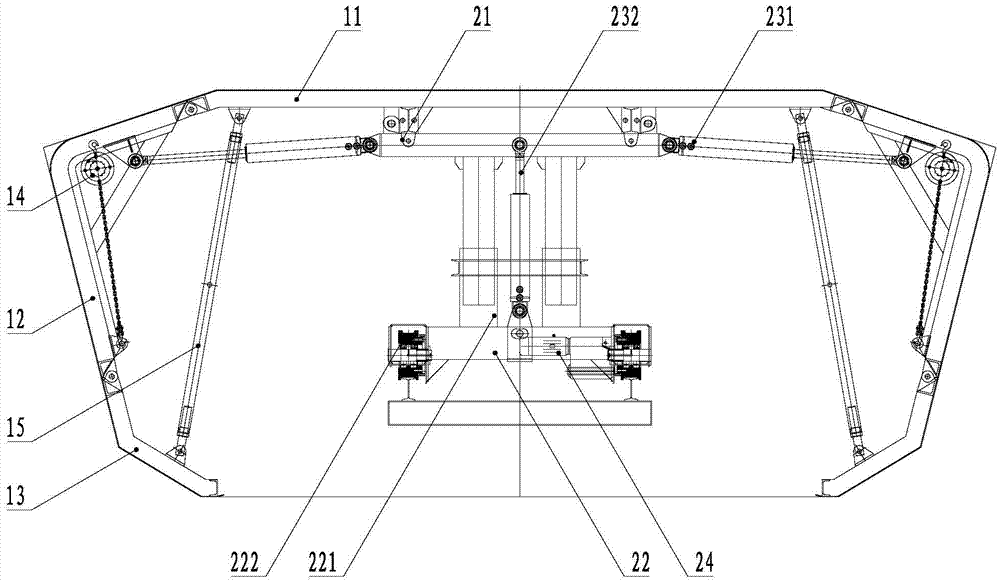

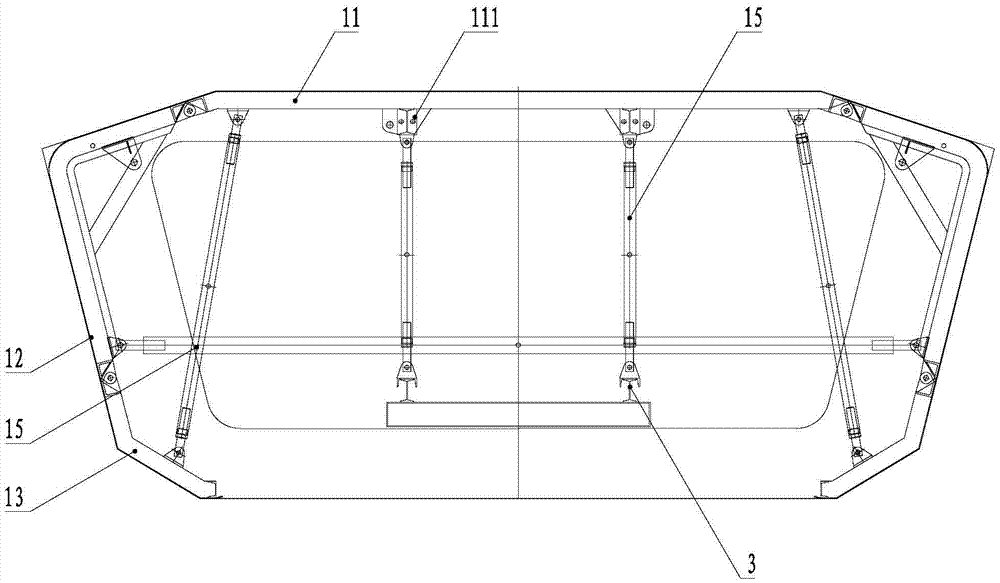

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the segmental self-propelled cast-in-place beam hydraulic inner mold provided by the present invention includes a template group, a mold moving device 2 and a track 3, and the mold moving device 2 consists of a mold moving trolley 22 and a guide set on the mold moving trolley 22. The column device 21, the lateral cylinder 231, the jacking cylinder 232, the hydraulic system 23 and the electrical system 24 are composed, the mold moving device 2 is movably connected with the segment formwork 1 through the guide column device 21, and the mold moving trolley 22 is arranged on the track 3, The formwork group is divided into several segment formworks 1 along the beam length direction, and each segment formwork 1 is composed of a top plate 11, an upper movable formwork 12 and a lower movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com