Plate bending angle detection device and method

A bending angle and detection device technology, applied in the field of detection, can solve the problems of insufficient measurement accuracy, bulky equipment, affecting the operation efficiency of the bending machine, etc., to reduce manual labor, high degree of automation, improve production efficiency and The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

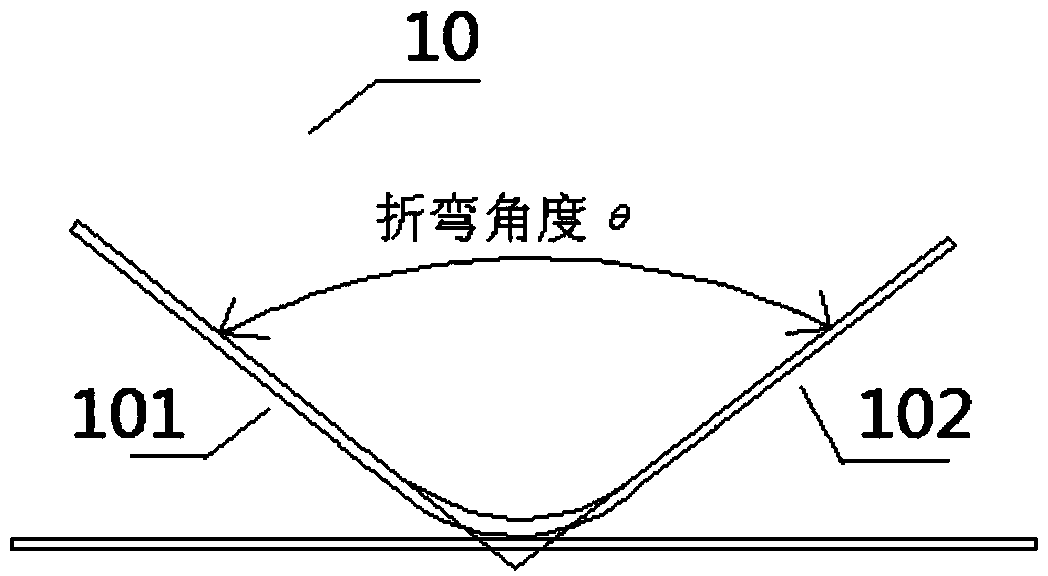

[0018] During the processing of the plate, it is often bent to form the desired shape. figure 1 It shows a schematic diagram of a shape of the plate after being bent. like figure 1 As shown, the sheet material 10 has a first portion 101 and a second portion 102, and the angle formed by the first portion 101 and the second portion 102 is called a bending angle θ. What the present invention provides is a device and method for detecting the bending angle θ.

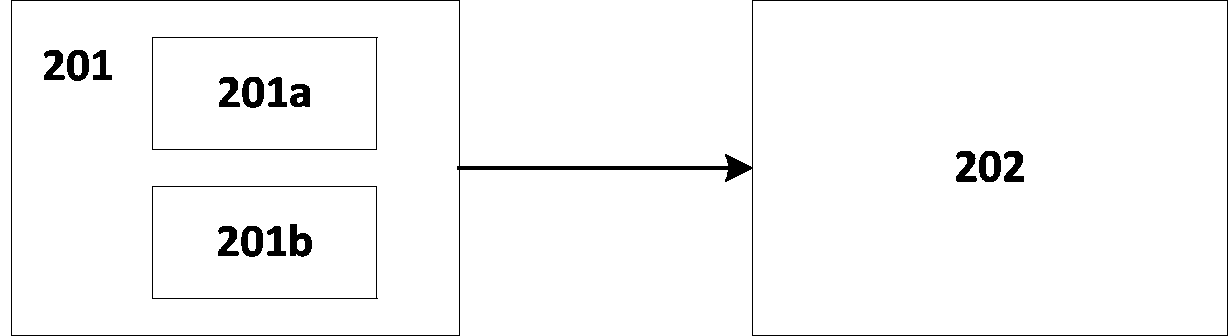

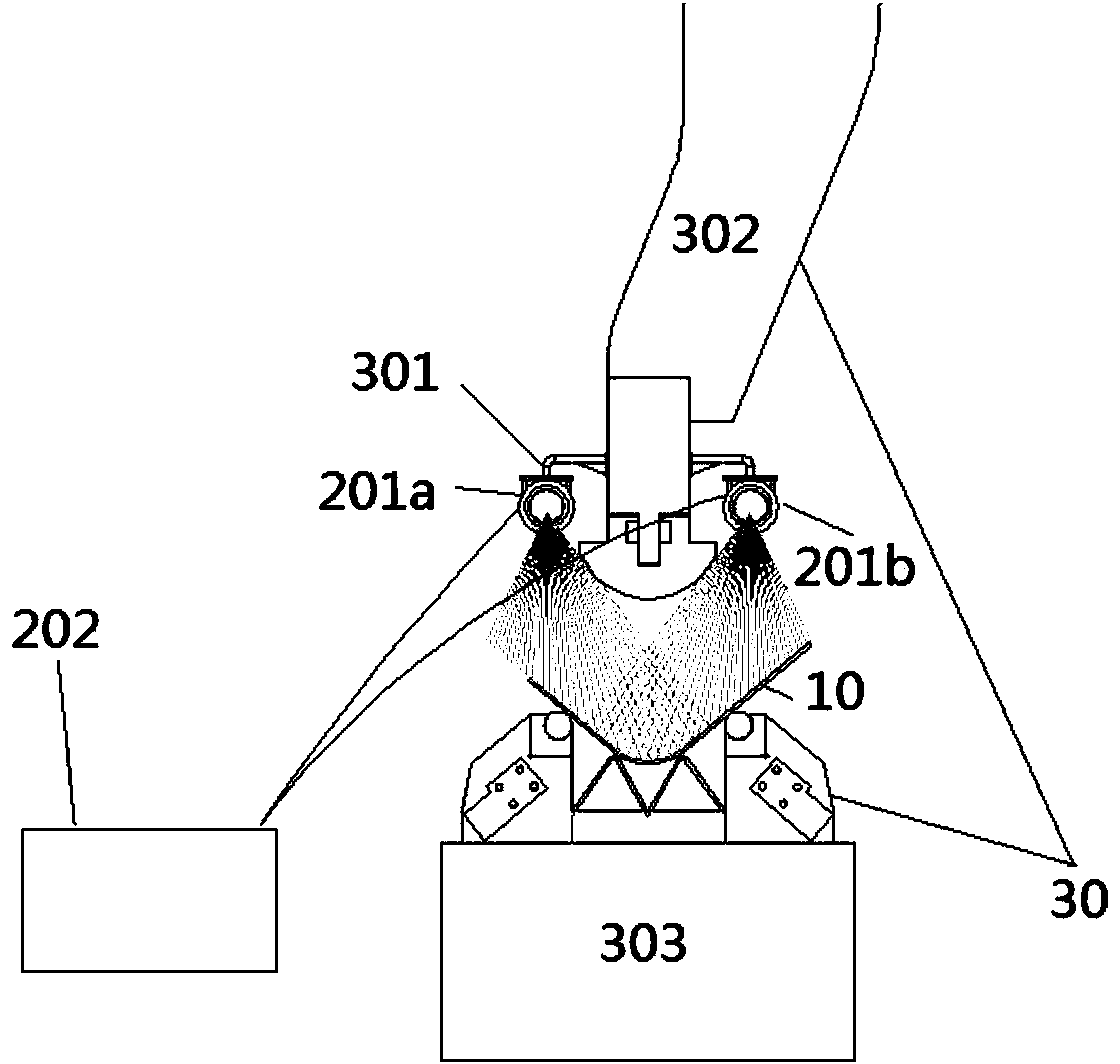

[0019] figure 2 The structure diagram of the plate bending angle detection device is shown. like figure 2 As shown, the device may include: a scanner 201, configured to emit a beam to the plate 10 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com