Steel and wood integrated I-shaped beam

A technology of I-beams and wooden beams, which is applied in the direction of formwork/formwork/work frame, connectors and structural elements of formwork/formwork/work frame, etc., which can solve the problems of inconvenient construction and installation, easy damage, and high cost , to achieve the effect of reducing transportation and storage costs, good versatility, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

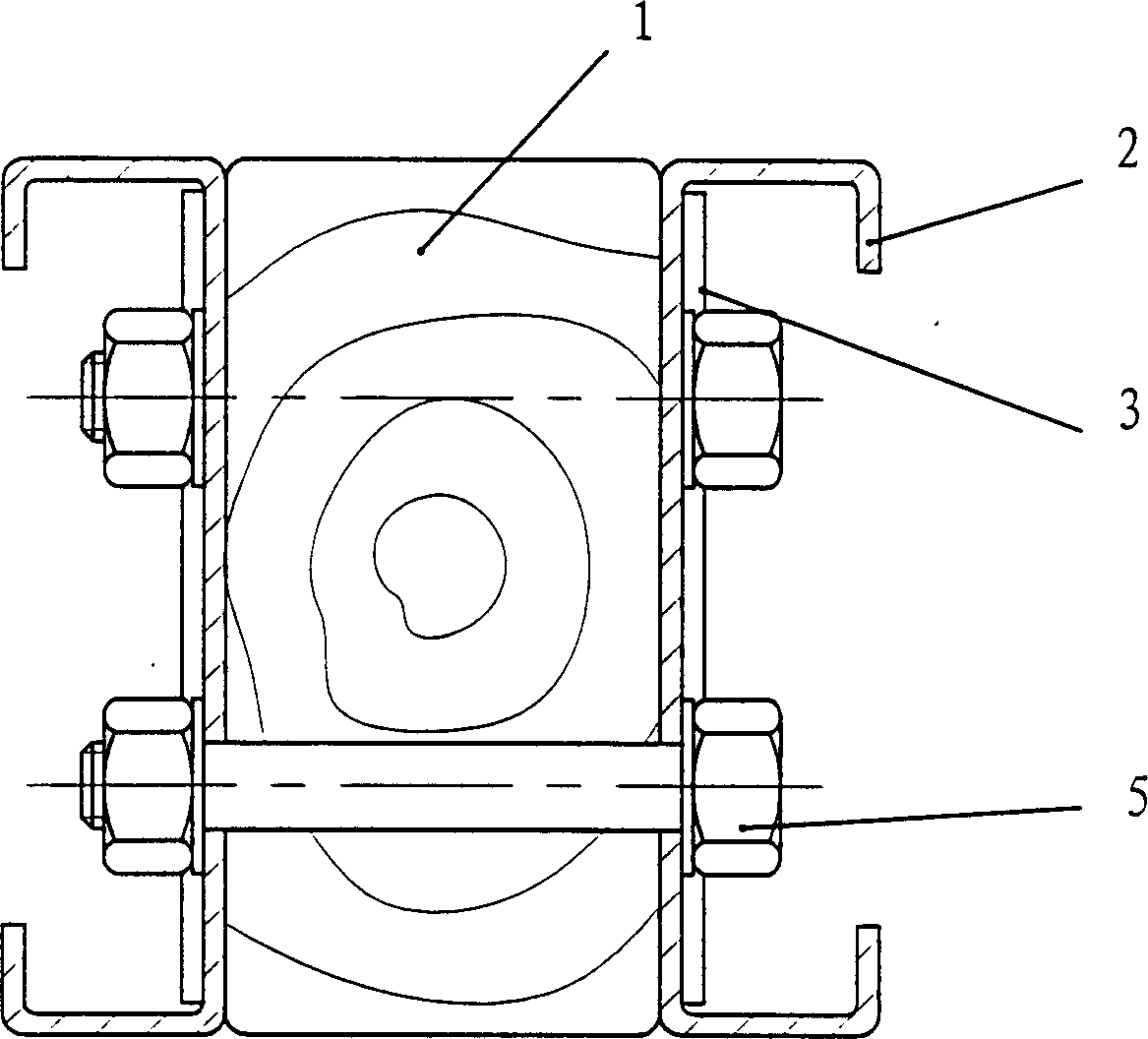

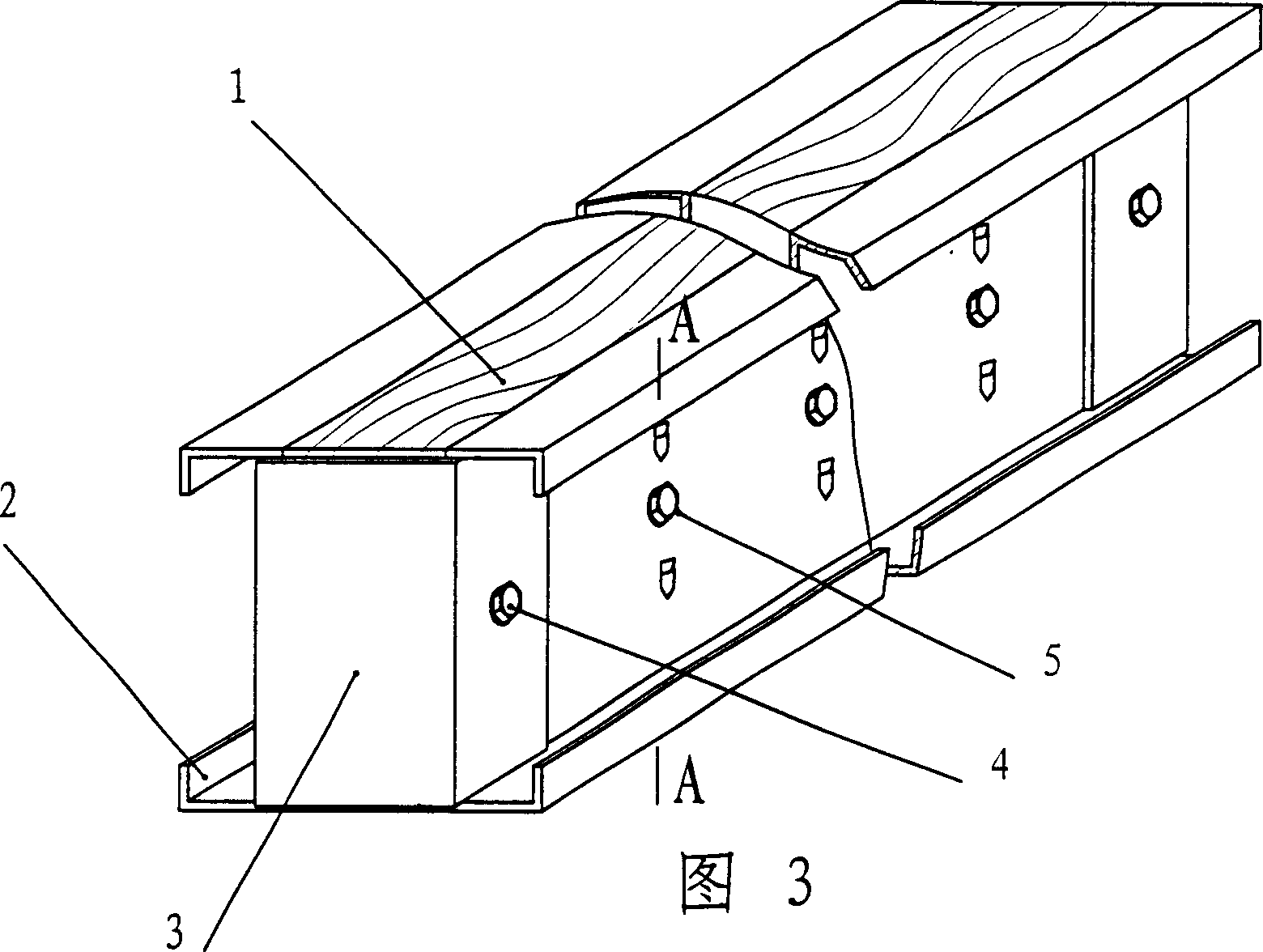

[0017] See figure 1 3, the steel-wood integrated I-beam of the present invention includes a wooden beam 1, the length of the wooden beam, its two wide sides, that is, the two sides that are placed vertically when in use are fixedly connected with the stressed steel 2, and the wooden beam A head 3 is fixedly connected with screws 4 at both ends. The connection between the wooden beam 1 and the stressed steel 2 or the head 3 can be connected by screws or rivets.

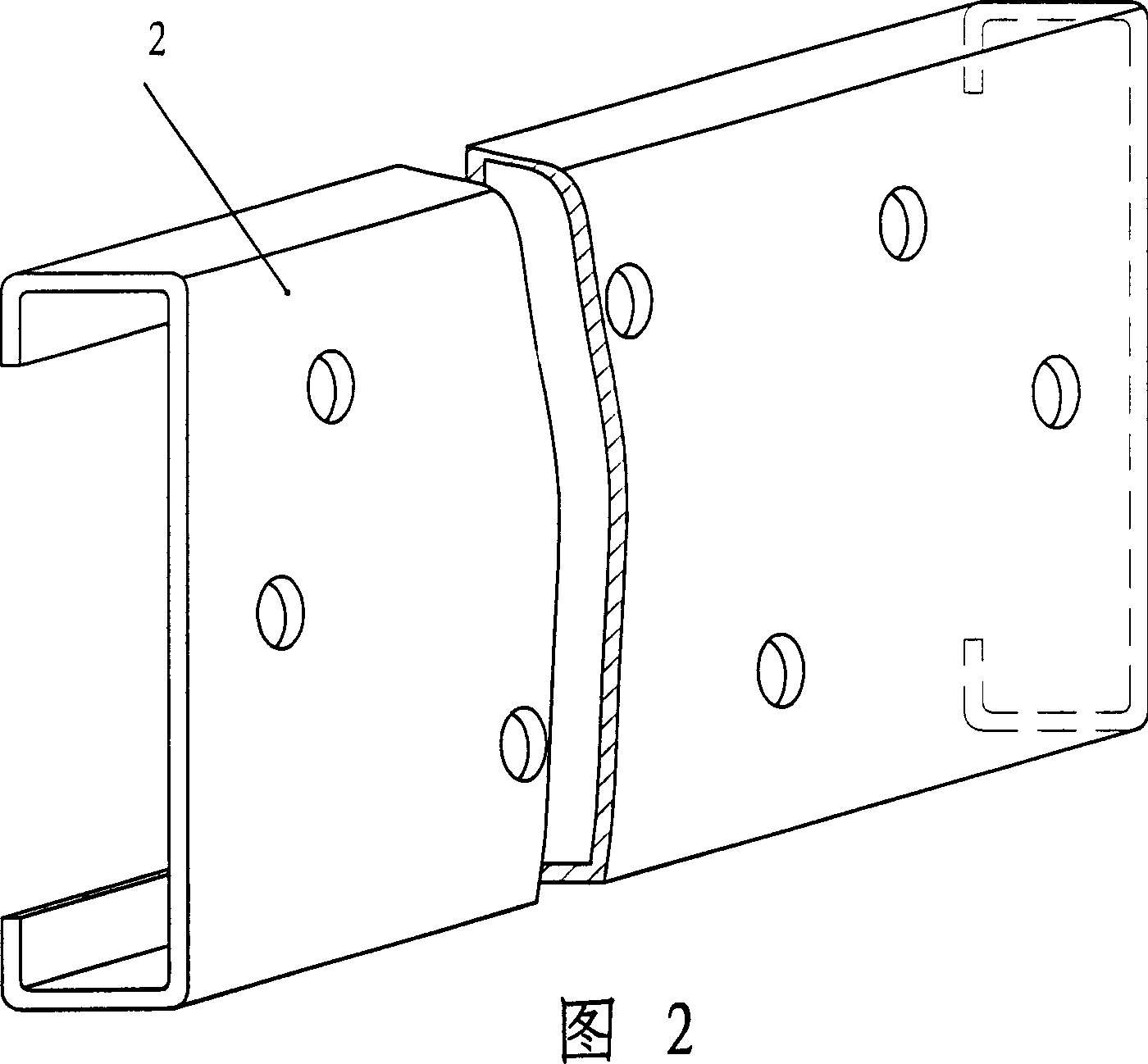

[0018] See Figure 2 and Figure 4 , The cross-sectional shape of the stressed steel 2 is a rectangular tube, one wide side has an opening that traverses the entire length, and on the other wide side, a row of through holes or two rows of upper and lower holes are evenly arranged in the length direction. Through holes to install screws. The number of through holes is determined by the length of the I-beam. Generally, the hole distance is about 50cm.

[0019] Referring to Figures 5 and 6, the stressed section steel 2 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com