Ultrahigh-toughness fiber-reinforced polymer modified cementitious composite and preparation method

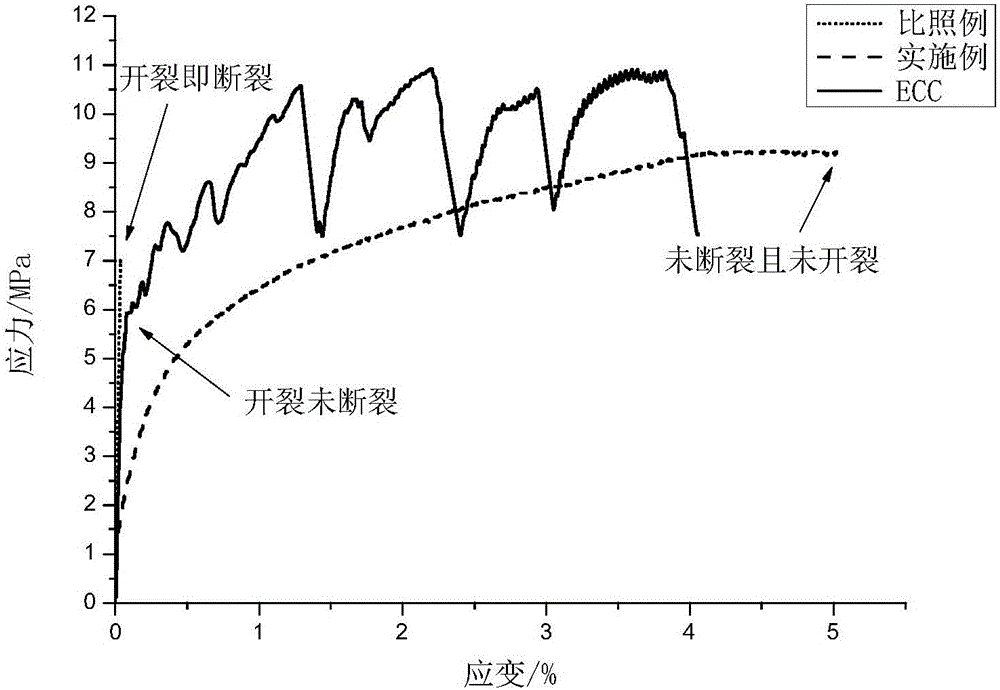

A fiber-reinforced, ultra-high toughness technology, applied in the field of building materials, can solve the problems of unpublished literature reports and high prices, and achieve the effects of high bending initial cracking stress, improved matrix deformation capacity, and increased strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

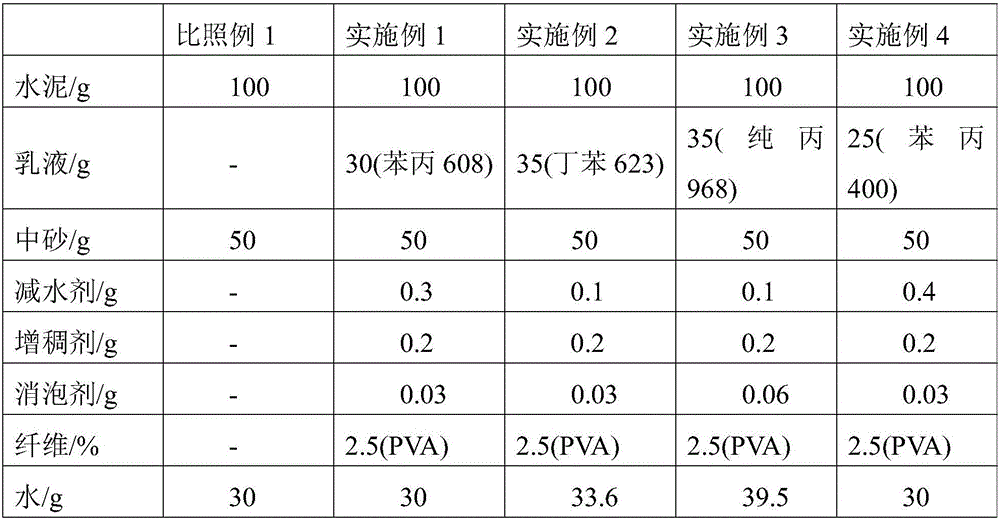

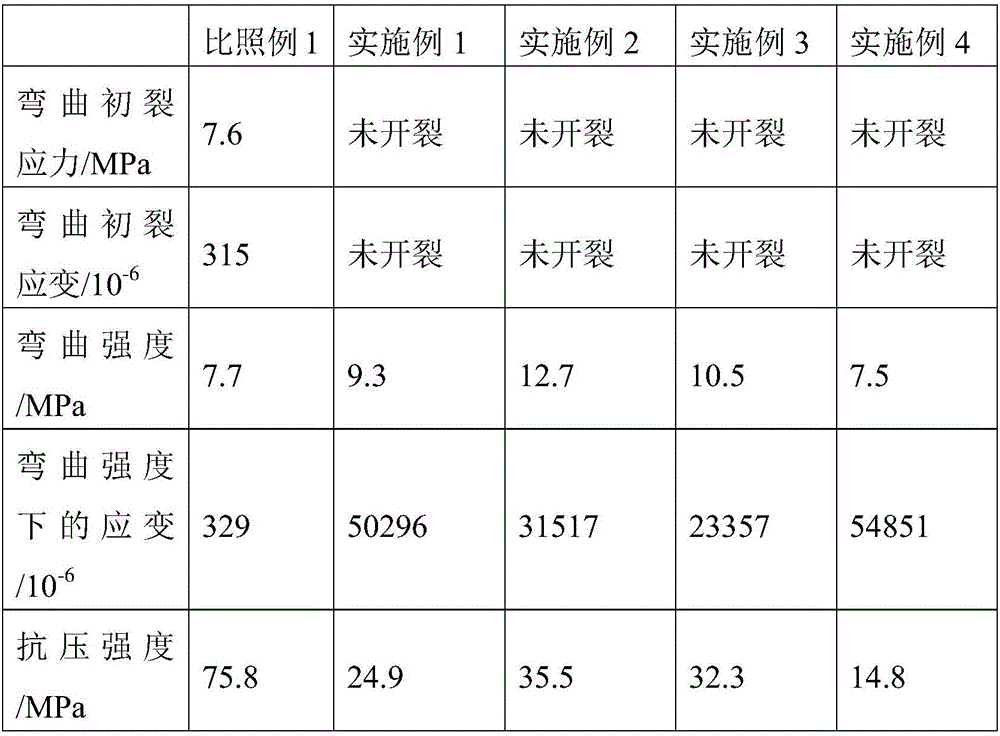

Embodiment 5

[0051] Ultra-high toughness fiber reinforced polymer modified cement-based composite material, prepared from ordinary portland cement, medium sand, polymer emulsion, synthetic polymer fiber, water reducer, defoamer, thickener and water , using the following formula by weight: Ordinary Portland cement 100, polymer emulsion (in terms of solid content) 25, medium sand 50, water reducer 0.1, thickener 0.1, water (including water contained in the emulsion) 30. Wherein, the synthetic polymer fiber accounts for 2.5% of the total volume of the composite material, and the defoamer accounts for 0.05% of the polymer emulsion quality. In this embodiment, the polymer emulsion is a styrene-acrylic emulsion with a solid content of 47%, and the synthetic polymer fiber is Polyvinyl alcohol fiber, the length is 10mm, the diameter is 15μm, the tensile strength is 1200MPa, the elastic modulus is 30GPa, the water reducer is polycarboxylate water reducer, the defoamer is emulsion defoamer, the thic...

Embodiment 6

[0058] Ultra-high toughness fiber-reinforced polymer modified cement-based composite material, prepared from cement, medium sand, polymer emulsion, synthetic polymer fiber, water reducer, defoamer, thickener and water, using the following weight Part formula composition: Ordinary Portland cement 100, polymer emulsion (calculated as solid content) 35, medium sand 50, water reducer 0.5, thickener 0.5, water 40, synthetic polymer fiber accounts for 2.5 of the total volume of the composite material %, the defoamer accounts for 0.05-0.2% of the mass of the polymer emulsion. The polymer emulsion is an emulsion for modifying cement mortar. In this embodiment, S400 styrene-acrylic emulsion with a solid content of 57% is used. The synthetic polymer fibers are polyvinyl alcohol fibers with a length of 15 mm, a diameter of 25 μm, a tensile strength of 1500 MPa, and an elastic modulus of 50 GPa. The water reducer is a polycarboxylate water reducer. The defoamer is an emulsion type defoa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com