Novel steel-fiber composite bar (SFCB) and engineered cementitious composite (ECC)-concrete composite beam and preparation method thereof

A continuous fiber and concrete technology, applied in the direction of joists, girders, trusses, etc., can solve the problems of poor ductility of FRP reinforced concrete beams, large crack width and deflection, insufficient durability of ordinary reinforced concrete beams, etc., so as to improve the structural durability. The effect of stability, reduced dosage, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The formula of each component of the cement-based composite material ECC for engineering is: cement: silica fume: fly ash: water: quartz sand: water reducing agent = (0.2~0.4): (0.1~0.15): (0~0.3): ( 0.15~0.2):(0.2~0.3):(0~0.0015), the fiber is PVA polyvinyl alcohol fiber, and the volume content is 2.0%.

[0039] The preparation method of engineering cement-based composite material ECC: Mix cement, quartz sand, silica fume, and fly ash with a mixer at low speed for 1 min to make the mixture evenly distributed; add water and stir at low speed for 1 min; add water reducing agent and stir at high speed for 2 min, the cement mortar can be self-leveling; finally add PVA fiber and stir at high speed for 6 min until the fiber is evenly dispersed.

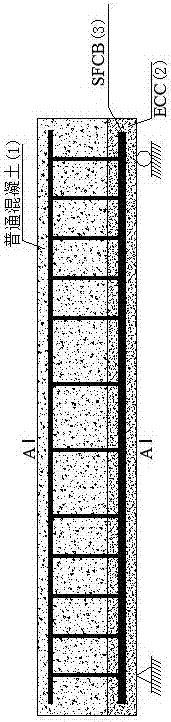

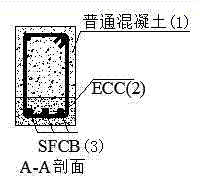

[0040] For a new type of steel-continuous fiber composite reinforcement ECC-concrete composite beam cast / prefabricated on site, the specific implementation steps are as follows:

[0041] (1) According to the structural construction...

Embodiment 2

[0047] For a new type of steel-continuous fiber composite reinforcement ECC-concrete composite beam cast / prefabricated on site, the specific implementation steps are as follows:

[0048] (1) Binding and placement of reinforcement cages are the same as Example 1.

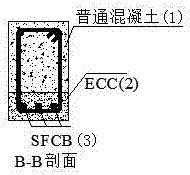

[0049] (2) The cement-based composite material ECC is used for engineering to pour a specific beam section. The pouring thickness is twice the thickness of the concrete protective layer of the longitudinal tension reinforcement. It can also be calculated and determined according to the actual situation. The length is 1 / 4~1 of the beam length / 2, the beam segment width is the same as the beam. And the beam segment is symmetrical to the moment control section of the beam.

[0050] (3) Pouring ordinary concrete, vibrating molding and curing are the same as in Example 1.

[0051] All material consumption and related dimensions need to be calculated and selected according to the needs of the actual project.

[0052] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com