Method for paving prefabricated coilable engineered cementitious composites (ECC)

A composite material, cement-based technology, used in road repair, climate change adaptation, roads, etc., can solve problems such as the paving of ECC materials that cannot be well adapted, the sustainability of reinforced concrete structures, and the lack of effective solutions for processes. , to achieve the effect of overcoming the late opening of traffic, the rapid opening of traffic, and shortening the construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

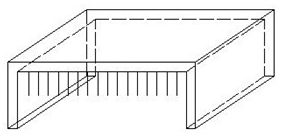

[0017] In the preparation of ECC components:

[0018] Prefabricated ECC components, the length is 100m~200, the width is 3~4m (adjusted according to the width of the lane), and the thickness is 1~5cm.

[0019] ② Composition of ECC materials: cement, fly ash, quartz sand, water, water reducing agent, polyvinyl alcohol fiber (PVA).

[0020] ③ The mixing ratio design of ECC materials, the mass ratio between cement: fly ash: quartz sand: water: superplasticizer is 1: 1.2: 0.8: 0.2: 0.013, and the content of PVA fiber is the total volume 2%. Among them, in order to reduce the amount of cement to reduce the cost, the content of fly ash can be increased to replace part of the cement, and the mass ratio of fly ash to cement can reach 5.6. At the same time, with the increase of the amount of fly ash, the ductility of ECC materials will increase. The increase will be more conducive to the crimping of prefabricated ECC components.

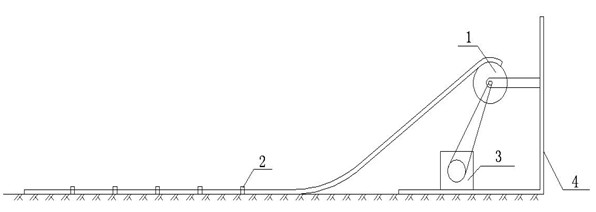

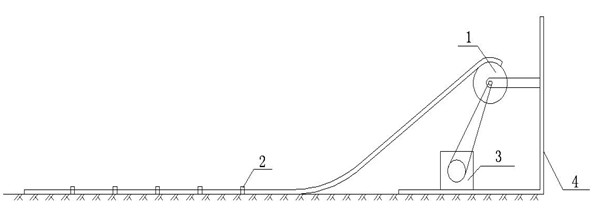

[0021] The operation of the process should me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com