Rubber-engineered cementitious composite and its preparation method

A composite material and high ductility technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as waste rubber pollution, achieve performance improvement, increase deformation capacity, and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

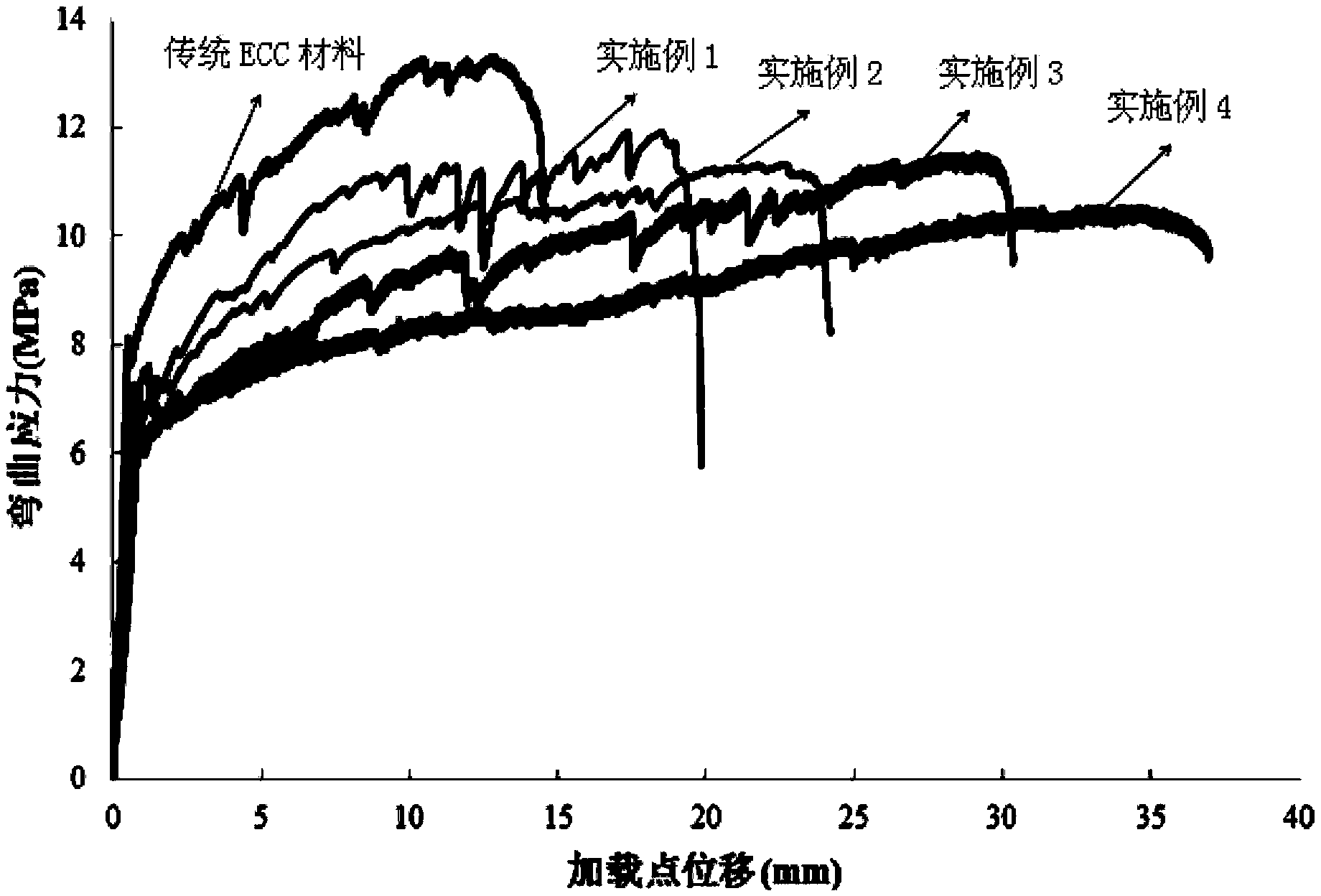

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] A rubber-high ductility cement-based composite material comprises the following components: cement, fly ash, water, water reducing agent and rubber additive, wherein the rubber additive is a mixture of rubber powder and quartz sand or rubber powder. Among them, the water reducer is a polycarboxylic acid type high-efficiency water reducer.

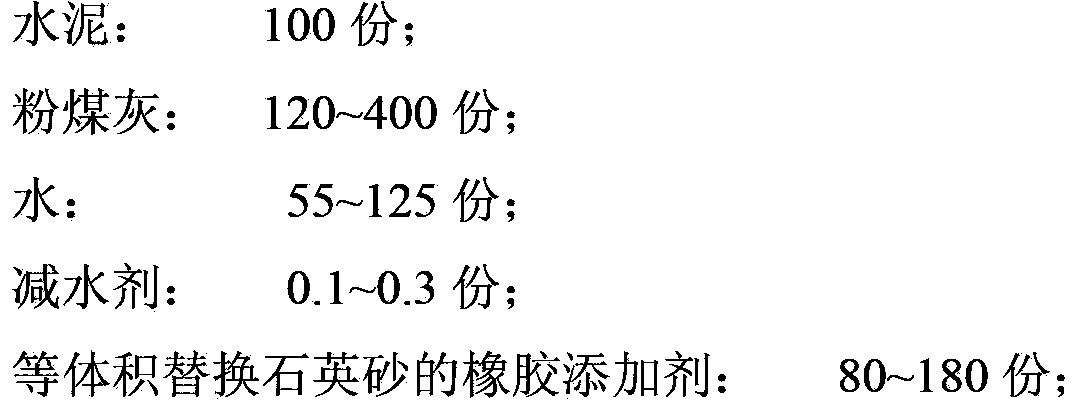

[0028] Further, in the present invention, the rubber additive is replaced with equal volume of quartz sand for calculation, then the mass parts of each component are:

[0029]

[0030] When proportioning, replace part or all of the quartz sand with rubber powder in equal volume;

[0031] In addition, polyvinyl alcohol fibers accounting for 1.5-2.5% of the total volume of the composite material are added.

[0032] Concrete each embodiment carries out proportioning according to the parts of each component as shown in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com