Graphene oxide modified cement-based composite material and preparation method thereof

A technology of graphene modification and composite materials, which is applied in the direction of climate change adaptation, etc., can solve the problems of ECC selection and performance defects, and achieve the effects of excellent strain hardening performance, high ductility, superior strain hardening performance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

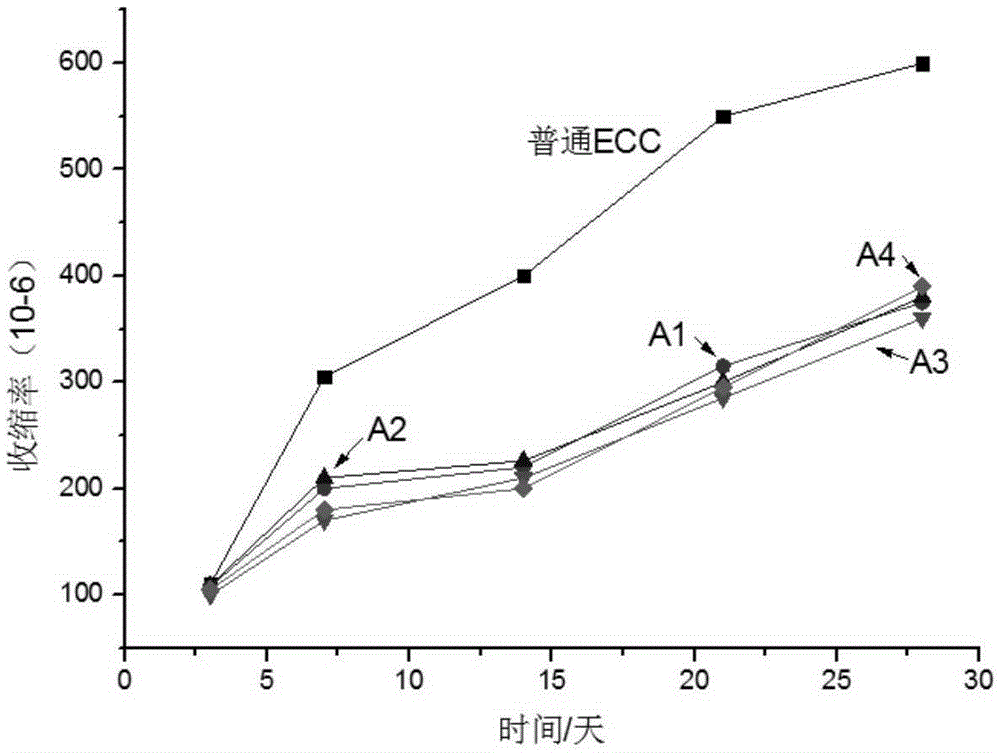

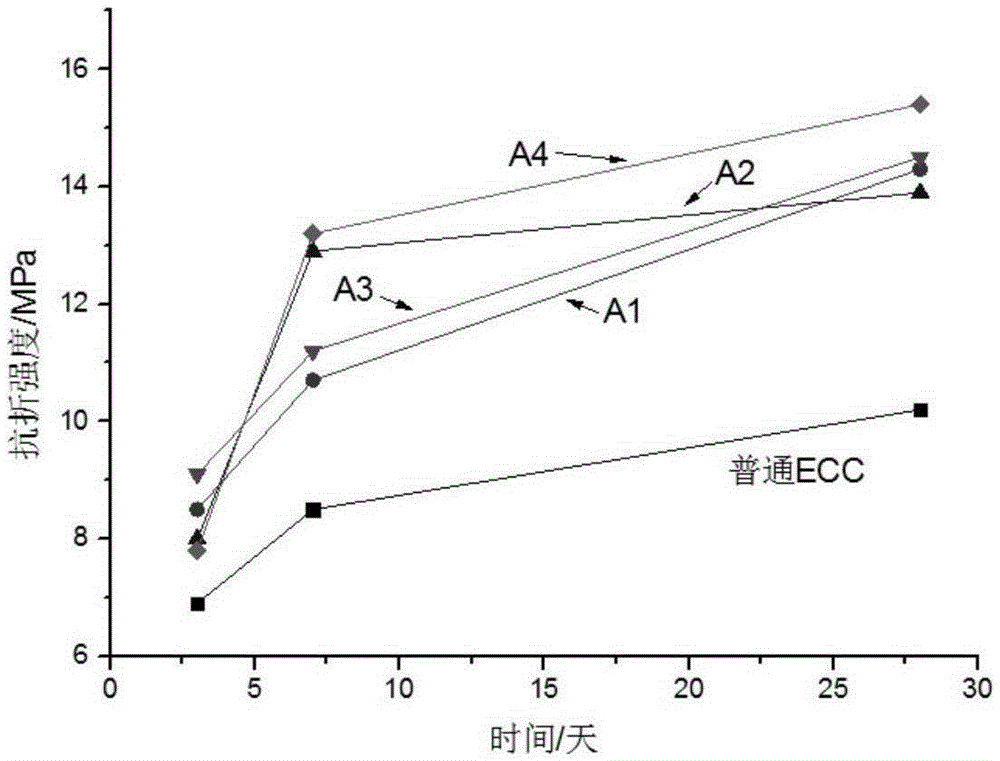

Embodiment 1-4

[0021] Concrete each embodiment carries out proportioning according to the parts of each component as shown in the table below:

[0022] project

Embodiment A1 / part

Embodiment A2 / part

Embodiment A3 / part

Embodiment A4 / part

cement

75

69

64

75

Quartz sand

150

173

194

160

75

69

45

60

water

23

18

19

27

Graphene oxide

0.06

0.05

0.05

0.06

Polycarboxylate superplasticizer

0.4

0.6

0.5

0.7

22

28

30

28

4.5

5.0

2.0

2.6

polyvinyl alcohol fiber

4.9

4.9

4

4.3

Shrinkage reducer

2.2

1.5

1.0

2.1

[0023] The cement described in the present invention is ordinary Portland cement, and the fly ash is secondary fly ash; the polymer is a styrene-butadiene emulsion with a solid content ≥ 48%, a pH value of 9.0-10.0, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com