ECC (engineered cementitious composite) durable type colored road pavement structure and paving method thereof

A laying method and durable technology, which is applied in the field of ECC durable colored pavement pavement structure and its laying, can solve the problems of easy falling off of gravel, rough surface, pedestrian safety, etc., so as to prevent aggregate falling off and improve thermal expansion resistance Cold shrinkage ability and the effect of improving road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The pavement structure is the ECC colored bus lane paved on the asphalt pavement:

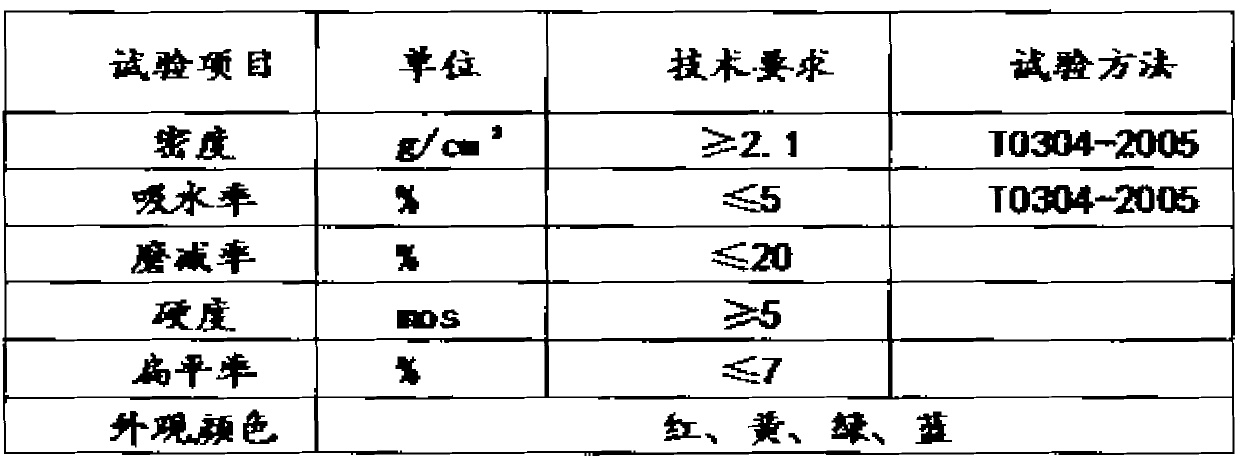

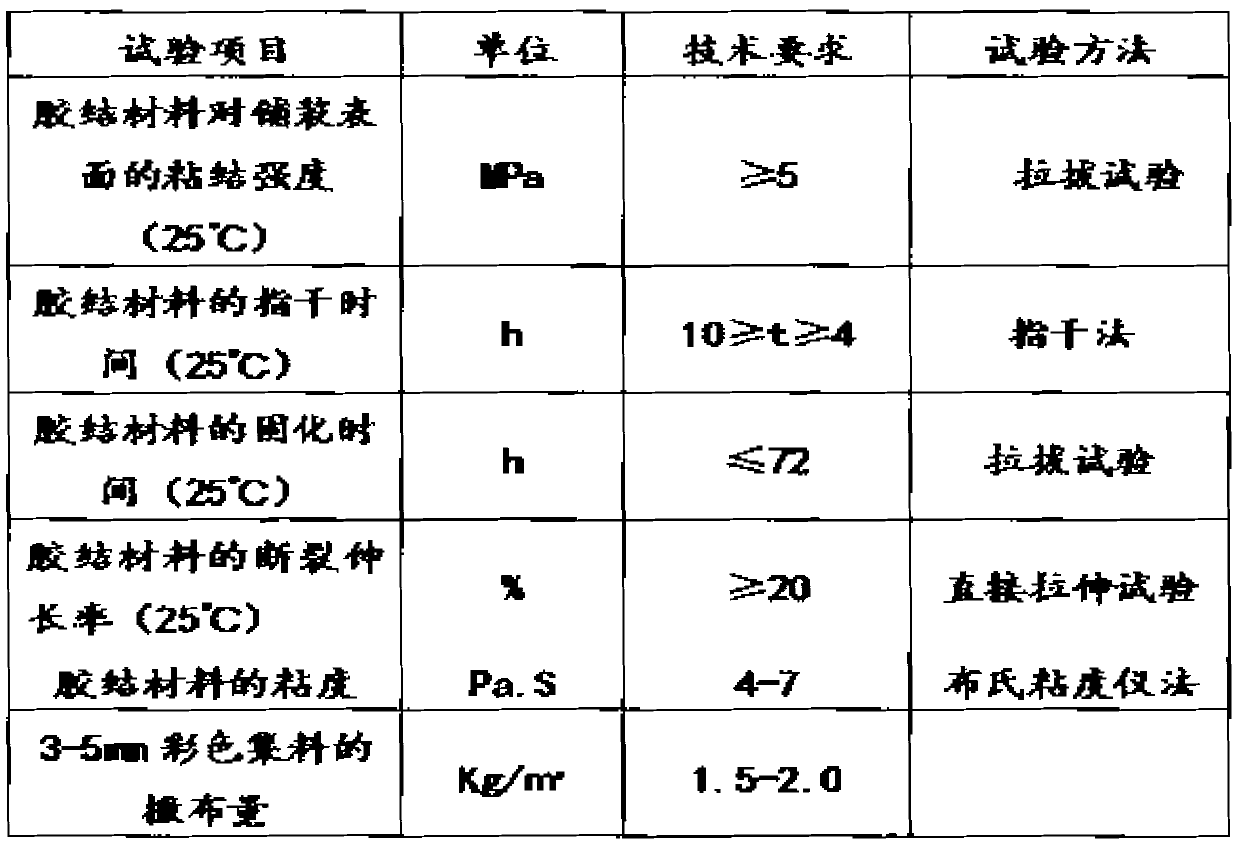

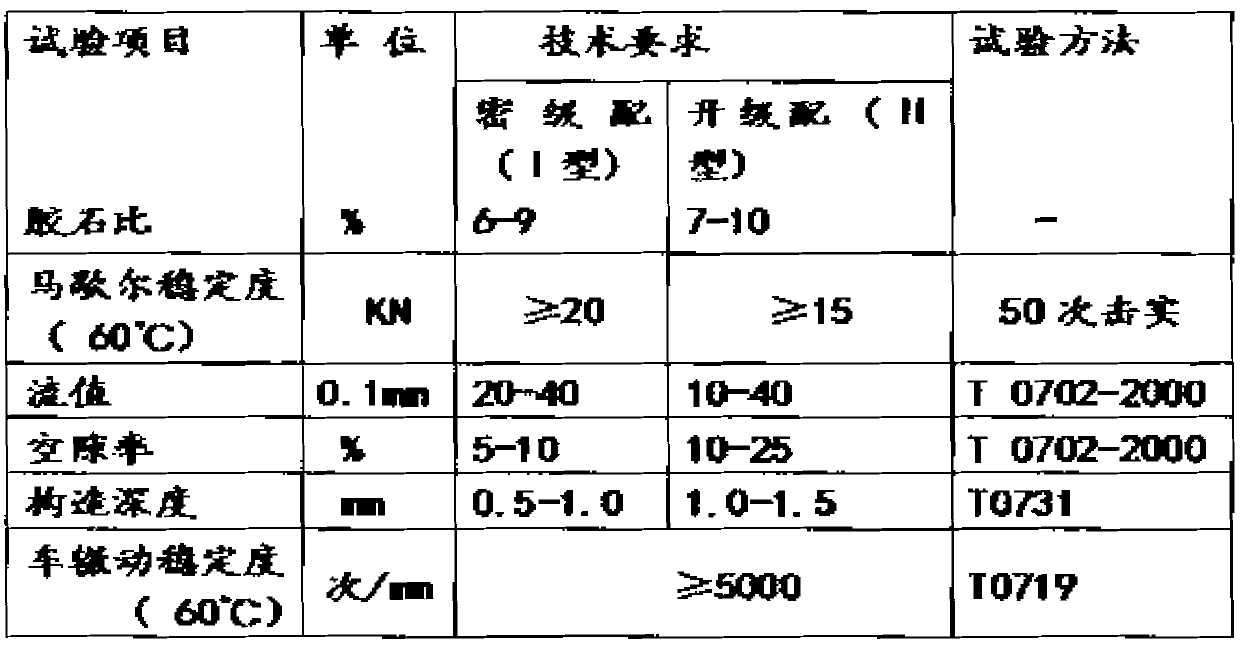

[0041] The pavement structure includes: an EC constrained base layer paved on the asphalt pavement 1 and a concrete surface course laid on the EC constrained base layer with epoxy resin as the cementing material, and the EC constrained base layer includes a cemented base layer made of epoxy resin The material layer and the color aggregate layer sprinkled on the bonding material layer; the thickness of the EC constraining bottom layer is 5mm, and the thickness of the concrete surface layer is 20mm.

[0042] Colored pavement design requirements: red bus lanes, design thickness 25mm, pavement must be flat, rough and free of water, pavement strength should meet the needs of the bus load operation.

[0043] The specific implementation steps are as follows:

[0044] ⑴ The elevation of the asphalt pavement should reserve the pavement thickness of the colored pavement, and the surface of the as...

Embodiment 2

[0058] The pavement structure of the present embodiment is paved on the reinforced concrete bridge deck ECC color landscape sidewalk, which includes paving on the reinforced concrete bridge deck EC constrained bottom layer and laying on the EC constrained bottom layer by epoxy resin as cementing material concrete The surface layer, the EC constrained bottom layer includes a cementitious material layer made of epoxy resin and a color aggregate layer sprinkled on the cemented material layer, the thickness of the EC constrained bottom layer is 3mm, and the thickness of the concrete surface layer is 7mm

[0059] Design requirements: The colored landscape pavement is directly paved on the sidewalk of the reinforced concrete bridge deck. The pavement thickness is 10mm.

[0060] The specific implementation steps are as follows:

[0061] ⑴Shot blasting is performed on the surface of the reinforced concrete bridge deck to make the surface cleanliness reach Sa2.0 level;

[0062] ⑵Prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com