Engineered cementitious composite (ECC) repairing material and preparation method thereof

A repair material, cement-based technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of high cost and long curing time of high-early-strength cement-based composite materials, and achieve good engineering applications value, reduce maintenance time, and ensure the effect of high elongation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A high-ductility cement-based composite repair material comprises the following components: cement, fly ash, quartz sand, water, water reducing agent, early strength additive and polyvinyl alcohol fiber. Among them, the early-strength additive is a composite early-strength agent provided by Jiangsu Subote New Material Co., Ltd., and the water-reducer is a polycarboxylic acid-type high-efficiency water-reducer.

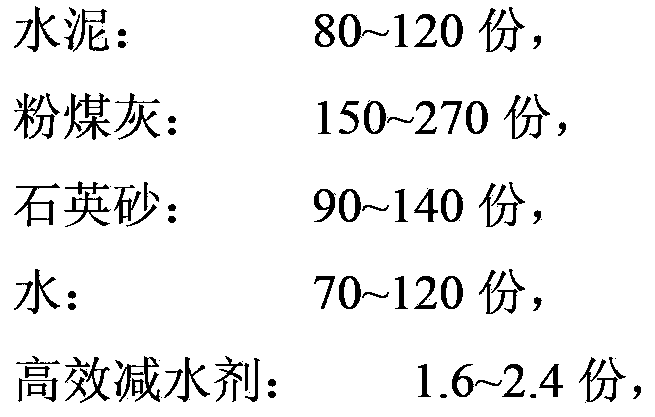

[0026] Further, in the present invention, the mass parts of the cement, fly ash, quartz sand, water, and water reducing agent are:

[0027]

[0028] Wherein, the mixture of cement and fly ash is called gel material, the quality of the early strength additive is 2.5-3.5% of the total mass of the gel material, and the volume of the polyvinyl alcohol fiber accounts for 1.5-2.5% of the total volume of the repair material. %.

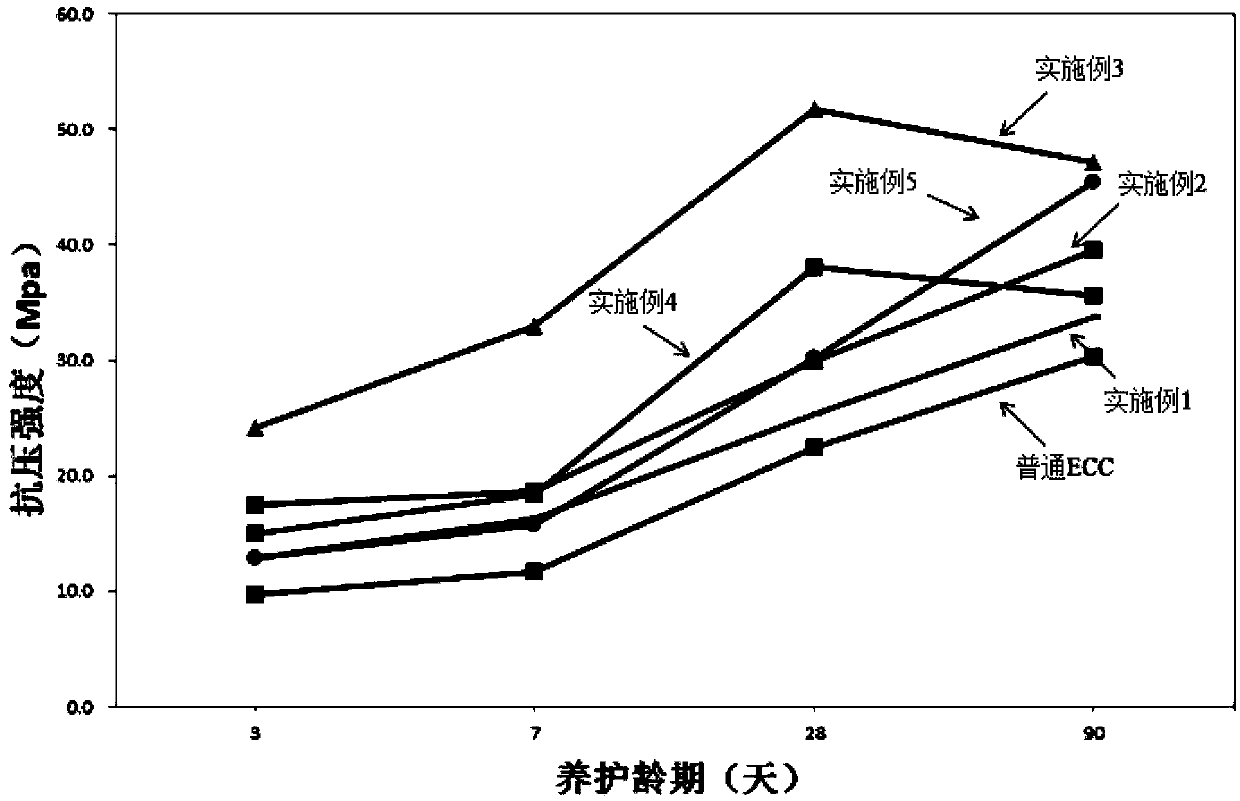

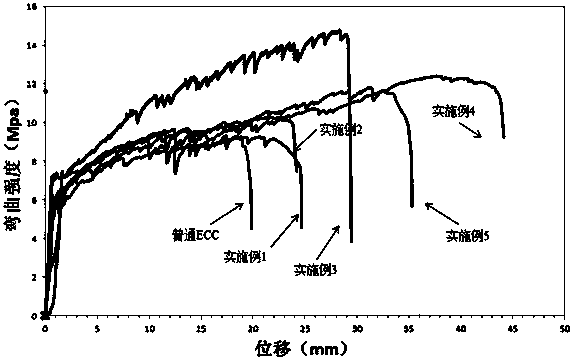

[0029] Concrete each embodiment carries out proportioning according to the parts of each component as shown in the table below:

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com